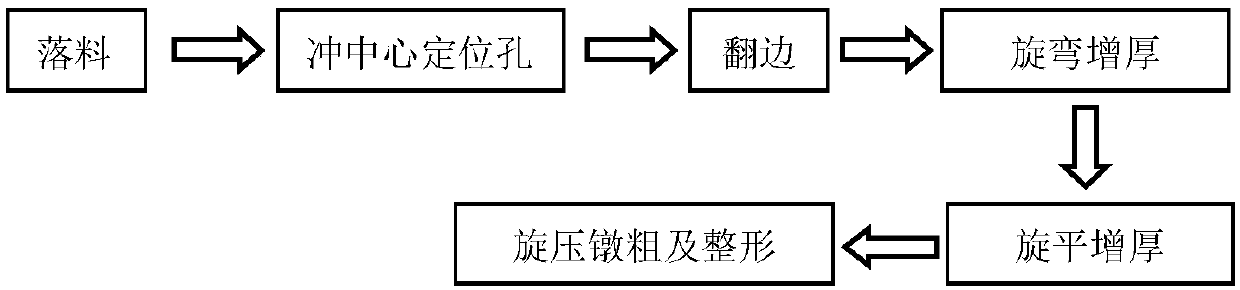

A method for forming plate-like parts with thin bottom and thick outer edge

A technology with outer edge and thin bottom, which is applied in vehicle parts, transportation and packaging, etc., can solve the problems of low production efficiency, poor mechanical properties and overall mechanical properties, high production cost, etc., achieve low equipment requirements, improve production efficiency and use The effect of less life and fewer forming passes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The integral spinning forming method is adopted for the dual-mass flywheel drive toothed plate 25 for an automobile, and the initial sheet material with a thickness of 3 mm is passed through the spinning forming process to form a dual-mass flywheel drive toothed plate 25 with an outer edge thickness of 10.5 mm, specifically including The following steps:

[0048] (1) Blanking: cutting and blanking the incoming plate with a thickness of 3 mm to obtain a circular blanking part 1;

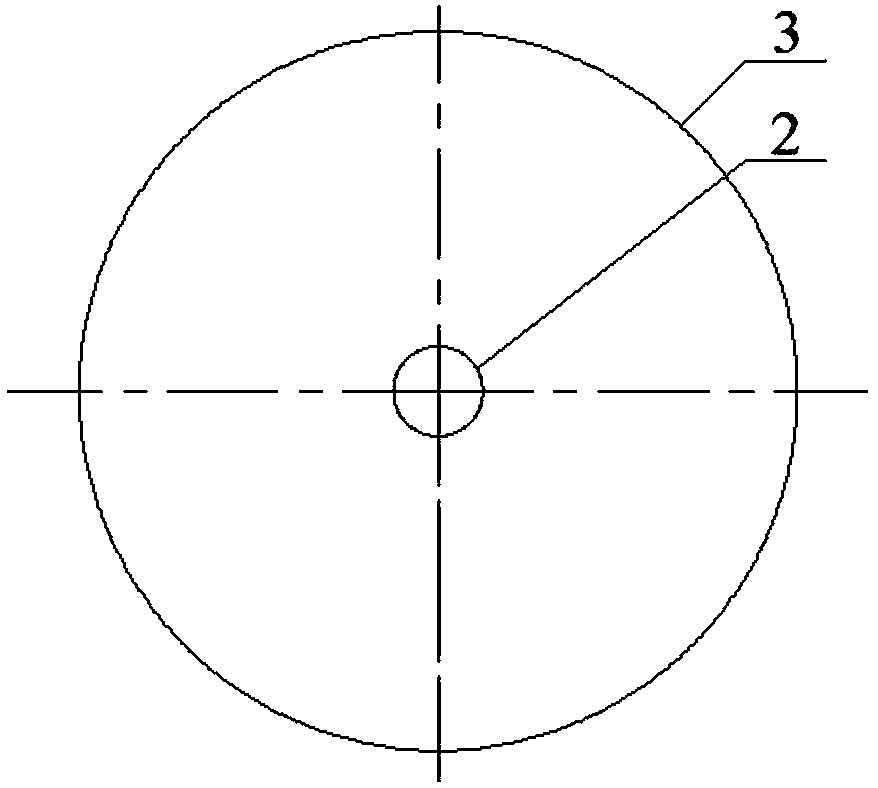

[0049] (2) Punch center positioning hole: carry out punching 2 (hole diameter is 40mm) to the blanking part center, make the punching part 3 with center positioning hole 2;

[0050] (3) flanging: flanging the peripheral edge of the punching part to obtain a flanging part 4 whose outer edge is a inferior arc shape;

[0051] (4) Thickening by turning: install the first mandrel on the turntable of the spinning machine, the mandrel rotation speed is 300r / min, and the flanging part 4 is coaxially i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com