A method for preparing concrete

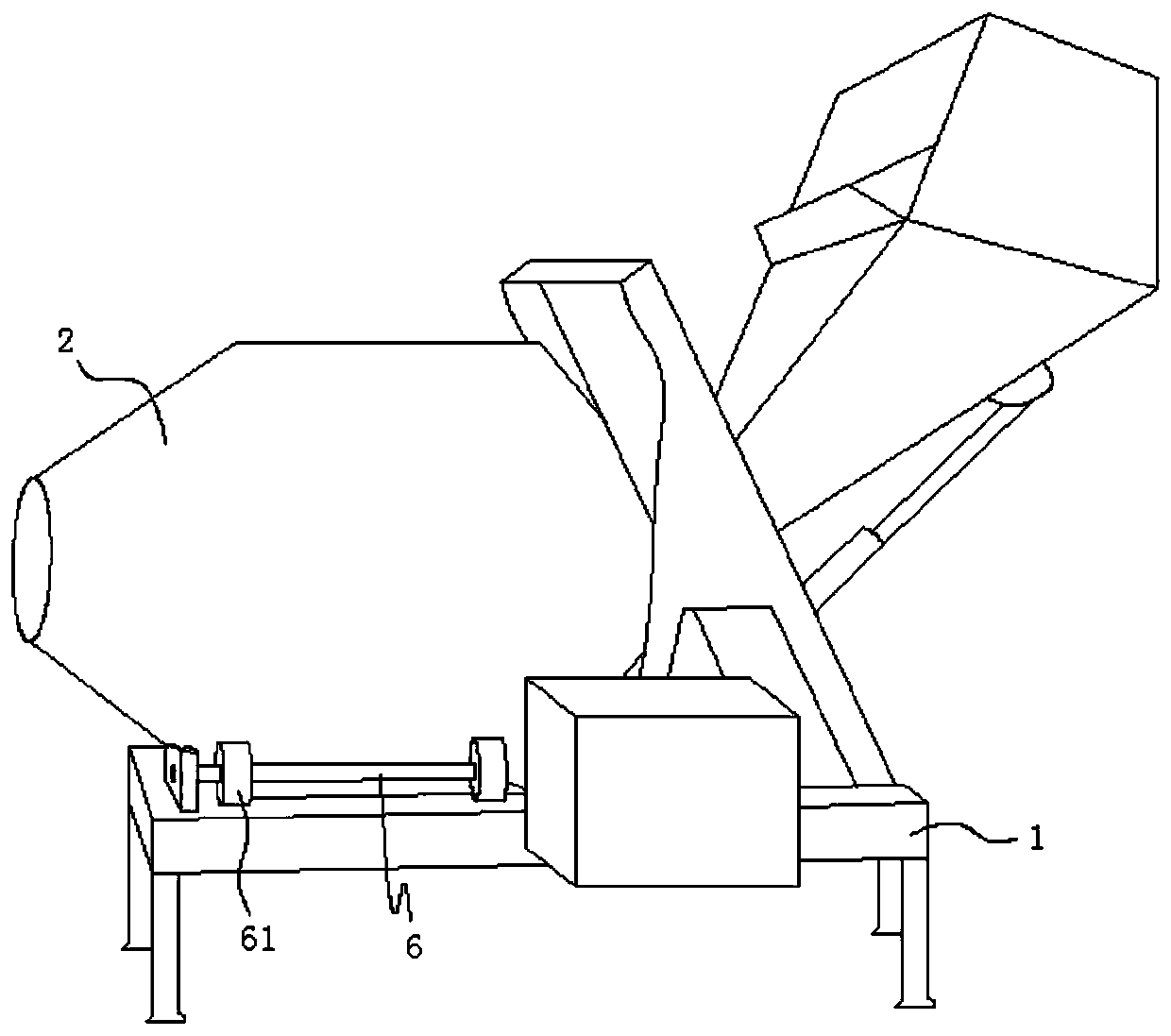

A technology for concrete and mixing equipment, which is applied in the direction of clay preparation equipment, chemical instruments and methods, cement mixing equipment, etc. It can solve the problems of affecting the use effect of concrete, destroying the ecological environment, and poor mixing effect, so as to reduce unit water consumption and avoid Effect of pollution and saving cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

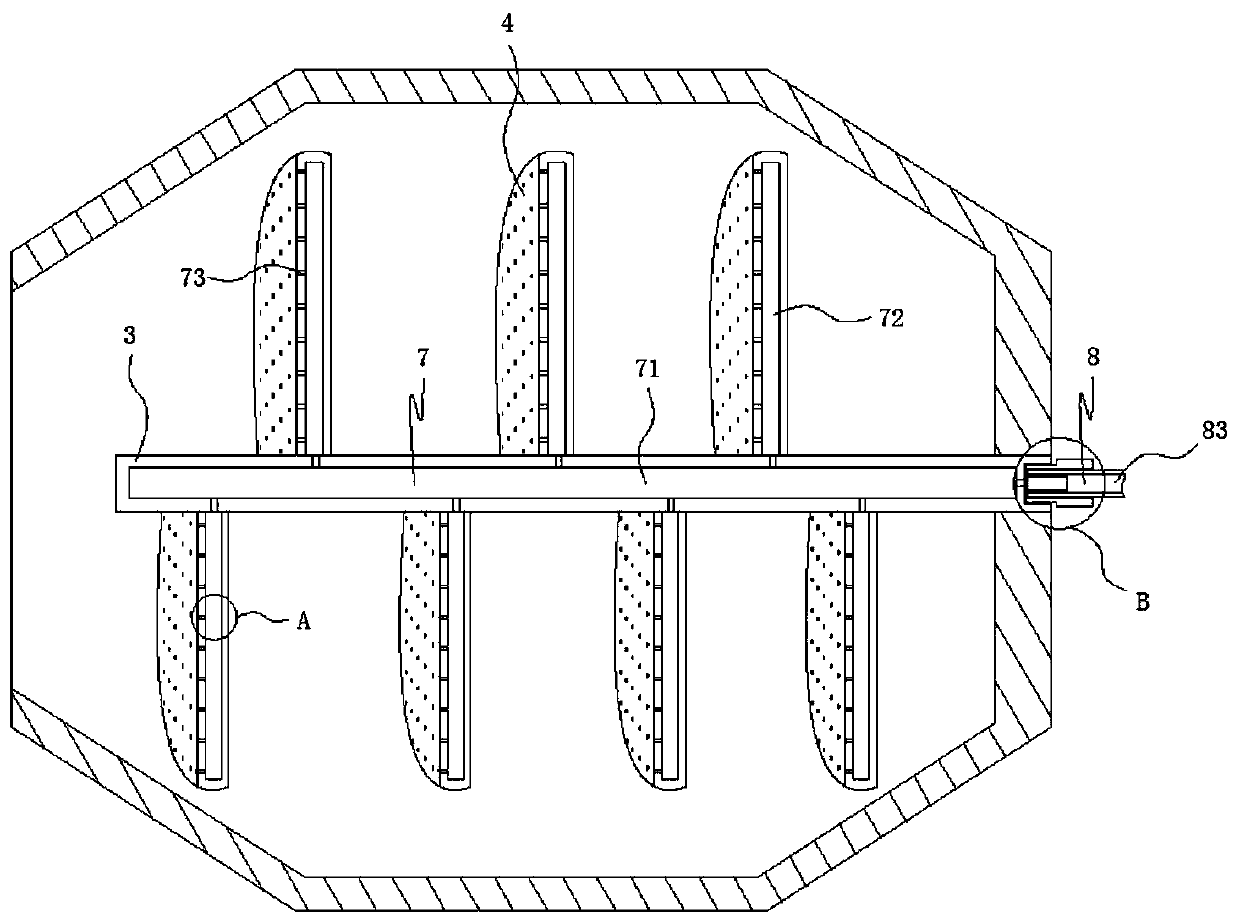

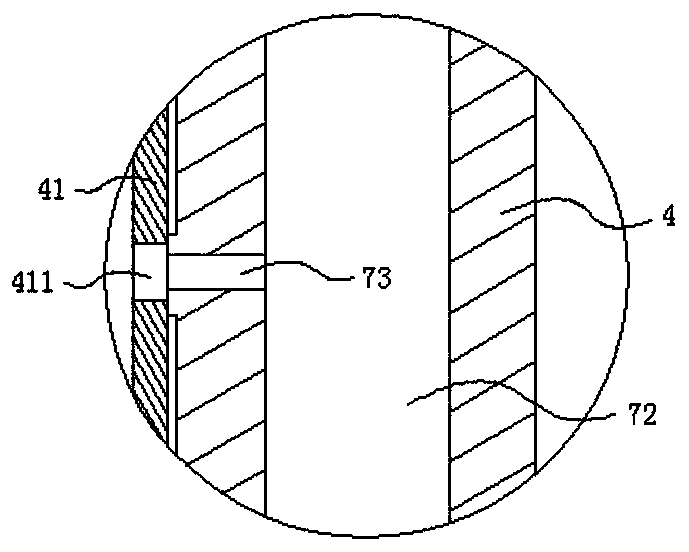

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing concrete includes the following steps: (1) Raw material acquisition: Obtain sludge, construction waste, coal ash, and cement, and put them into mixing equipment at 1:1.5:1.2:2.5; specifically, The sludge is the sediment in the primary sedimentation tank of sewage treatment, which is scraped out by scraping equipment. The scraping equipment is realized by the prior art, so it will not be repeated; secondly, the sludge is put into the mixing equipment Before the inside, the sludge is deodorized. The specific operation is as follows: Put calcium oxide into the sludge at a ratio of 2:1, mix it with a rake, and let it stand for 20 minutes; after the standing is completed, find a piece of it outdoors Cement ground, and then spread the sludge on the cement floor with a rake, then air dry and air dry until the sludge is naturally air-dried and hardened; then put the air-dried sludge into a crusher for crushing and crushing After the completion of the 80-me...

Embodiment 2

[0041] A method for preparing concrete includes the following steps: (1) Raw material acquisition: Obtain sludge, construction waste, coal ash, and cement, and put them into mixing equipment at 1:1.3:1.1:2.3. The structure is the same as that in Example 1, so it will not be repeated; specifically, the sludge is the sediment in the primary sedimentation tank of sewage treatment, which is scraped out by a mud scraping device, and the mud scraping device is a prior art. It is realized, so it will not be repeated; secondly, before the sludge is put into the mixing equipment, the sludge is deodorized, and the specific operation is as follows: put calcium oxide into the sludge at a ratio of 2:1, and stir and mix with a rake After uniformity, let stand for 25min; after the rest is complete, find a piece of cement floor outdoors, then spread the sludge on the cement floor with a rake, and then air dry and air dry until the sludge is naturally air-dried and hardened ; Afterwards, the ai...

Embodiment 3

[0044] A method for preparing concrete includes the following steps: (1) Raw material acquisition: Obtain sludge, construction waste, coal ash, and cement, and put them into mixing equipment at 1:1.5:1.2:2.5. The structure is the same as that in Example 1, so it will not be repeated; specifically, the sludge is the sediment in the primary sedimentation tank of sewage treatment, which is scraped out by a mud scraping device, and the mud scraping device is a prior art. It is realized, so it will not be repeated; secondly, the sludge is deodorized before being put into the mixing equipment. The specific operation is as follows: Put calcium oxide into the sludge at a ratio of 2:1, and stir and mix with a rake After uniformity, let stand for 30 minutes; after the standing is completed, find a piece of cement floor outside, then spread the sludge on the cement floor with a rake, and then dry it naturally, until the sludge is naturally air-dried and hardened ; Afterwards, the air-drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com