Intelligent test system and method of hydraulic disk brake of petroleum drilling machine

A test system and hydraulic technology, applied in the field of oil drilling, can solve the problems of inaccurate manual operation of hydraulic disc brakes, troublesome operation of hydraulic disc brakes, and large impact, and achieve the effects of eliminating risks, simple operation, and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

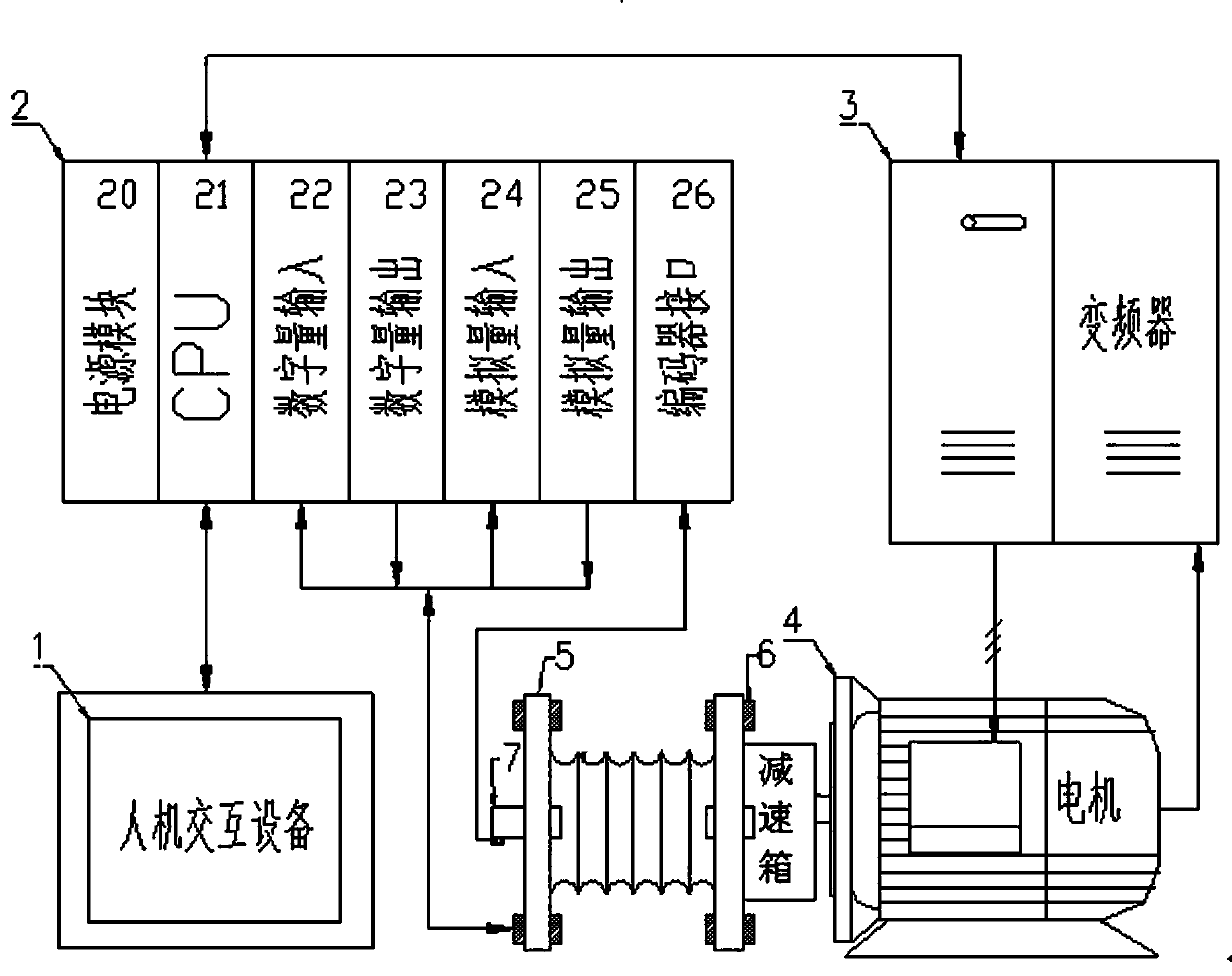

[0031] Attached below Figure 1-5 The present invention is described in further detail:

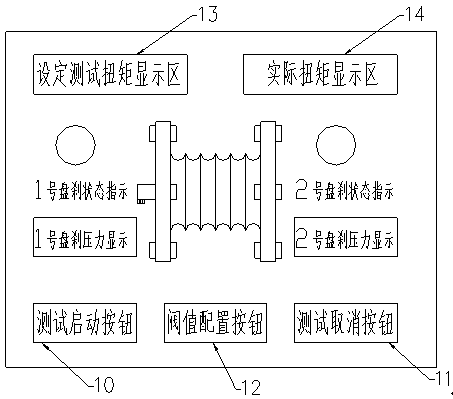

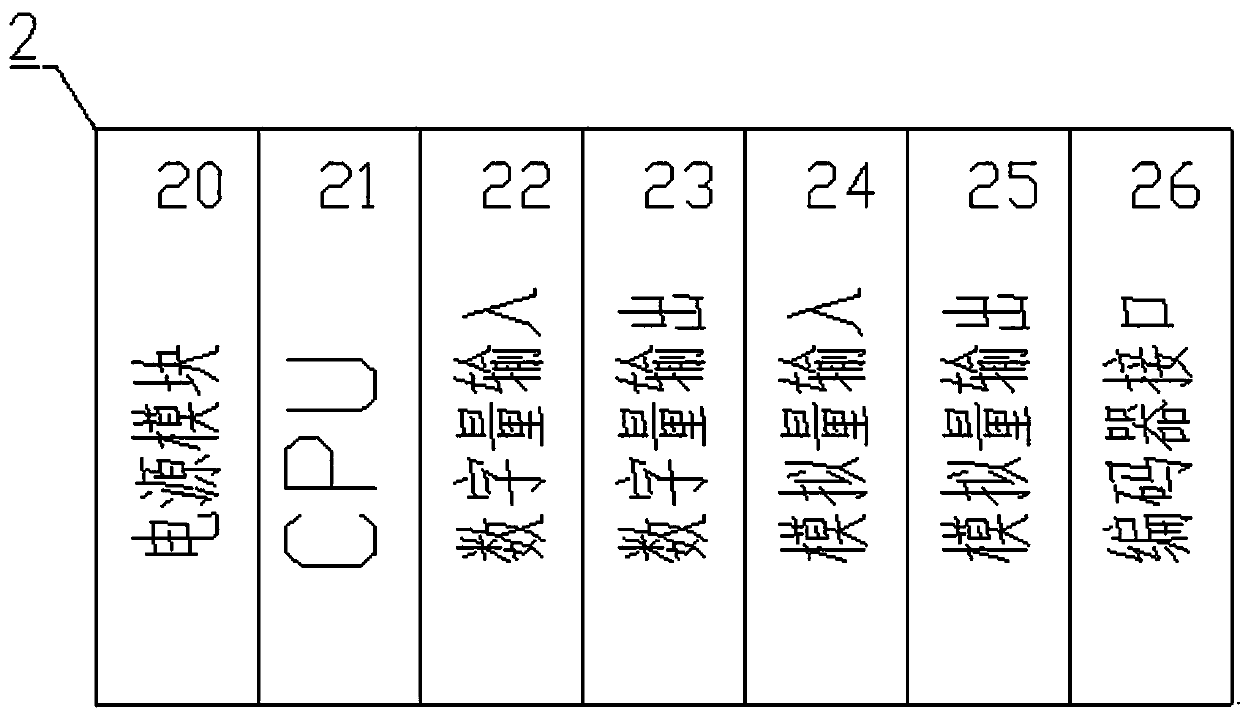

[0032] The intelligent testing system for hydraulic disc brakes of oil drilling rigs of the present invention includes a visual human-computer interaction device 1, a programmable controller 2, a frequency converter 3, a motor 4, a winch drum 5, a hydraulic disc brake 6, a winch drum encoder 7, and the like. Visualized human-computer interaction device 1, equipped with output fields of No. 1 and No. 2 hydraulic disc brake pressures, status indicator lights of No. 1 and No. 2 hydraulic disc brakes, a test start button, a threshold configuration button, a test cancel button, and a set and measured torque input domain, and the actual torque display domain; it provides an interactive interface for the user to select the operation object, set the parameters and select the operation action, and encode and correct the information selected and set; the winch drum encoder 7 is used to judge The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com