Hydraulic self-heating sucker-type water cup

A hot straw type, straw technology, applied in drinking vessels, engine components, machines/engines, etc., to achieve the effect of good development space, novel design, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

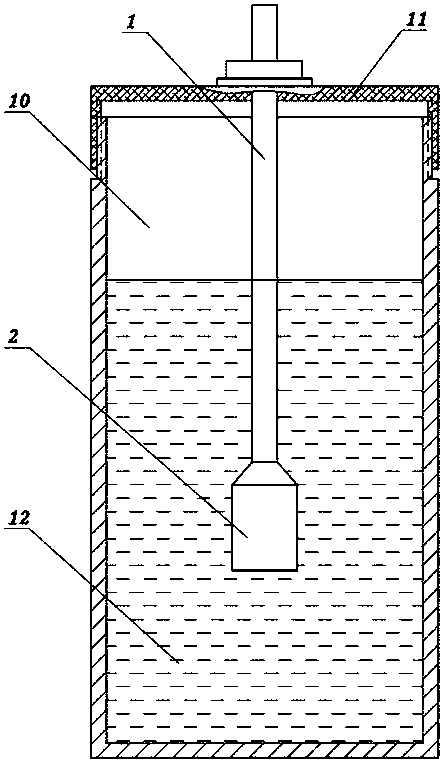

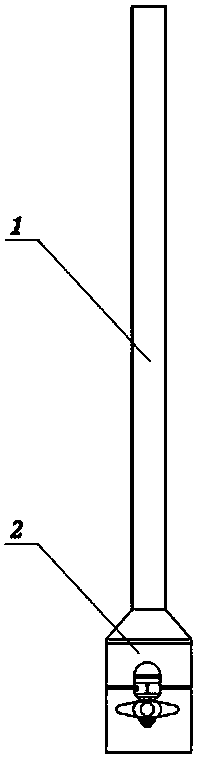

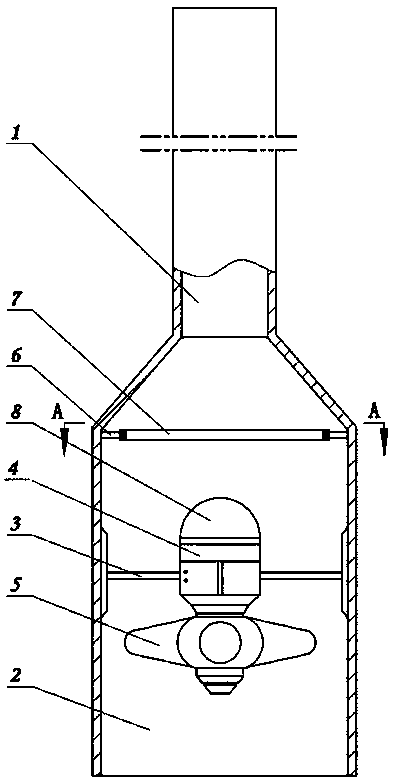

[0022] Example 1: The first hydraulic self-heating straw type water cup, such as figure 1 As shown, necessary components such as the cup body 10, the cup lid, and the straw are included. See figure 2 As shown, the straw includes a straw body 1 on the upper side and a straw heating section 2 on the lower side. The upper end of the straw body 1 leads out of the cup 10 and the straw heating section 2 is located at the bottom of the cup 10.

[0023] Such as image 3 As shown, the middle part of the heating inner wall of the straw is fixed with a reversible hydro-generator 4 through a bracket. The shaft of the reversible hydro-generator 4 coincides with the shaft of the heating section 2 of the straw. The turbine blades are installed on the shaft. The resistance wire 7 is fixed on the upper side of the heating section 2 of the straw. The power output end of the reversible water turbine generator 4 is connected to both ends of the resistance wire 7.

[0024] The resistance wire 7 used ...

Embodiment 2

[0030] Example 2: On the basis of Example 1, see Figure 4 , The straw body 1 and the straw heating section 2 have a sealed butt joint structure, and the two parts are processed separately and assembled together.

[0031] In addition, see Image 6 As shown, the resistance wire 7 used in this embodiment is a spiral disc-shaped structure, which is connected to the middle of the straw heating section 2 respectively. Conducive to full contact with water flow to achieve heat exchange.

Embodiment 3

[0032] Embodiment 3: On the basis of embodiment 1 or embodiment 2, a connecting seat 13 is provided on the upper side of the cup lid and located outside the straw body 1, and a connecting seat 13 is installed on the lid that can be flipped and buckled. The upper secondary cover can seal the port of the straw body 1.

[0033] For specific structure, see Figure 7 As shown, the secondary cover is a rotating secondary cover 16 whose two sides are respectively hinged on both sides of the connecting seat 13 by pins 14. After the rotating secondary cover 16 is turned over, the upper port of the straw body 1 can be secondary covered. A fixed arc-shaped shell 15 is sleeved on the outer side of the rotating auxiliary cover 16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com