Bracket positioning guide plate and manufacturing method, bracket positioning gauge and bracket positioning method

A positioning plate and positioner technology, which is applied in the field of orthodontics, can solve the problems of inaccurate pasting position, unsynchronized acid etching, inconvenient operation, etc., and achieve the effects of preventing acid etching from being too long, saving time, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

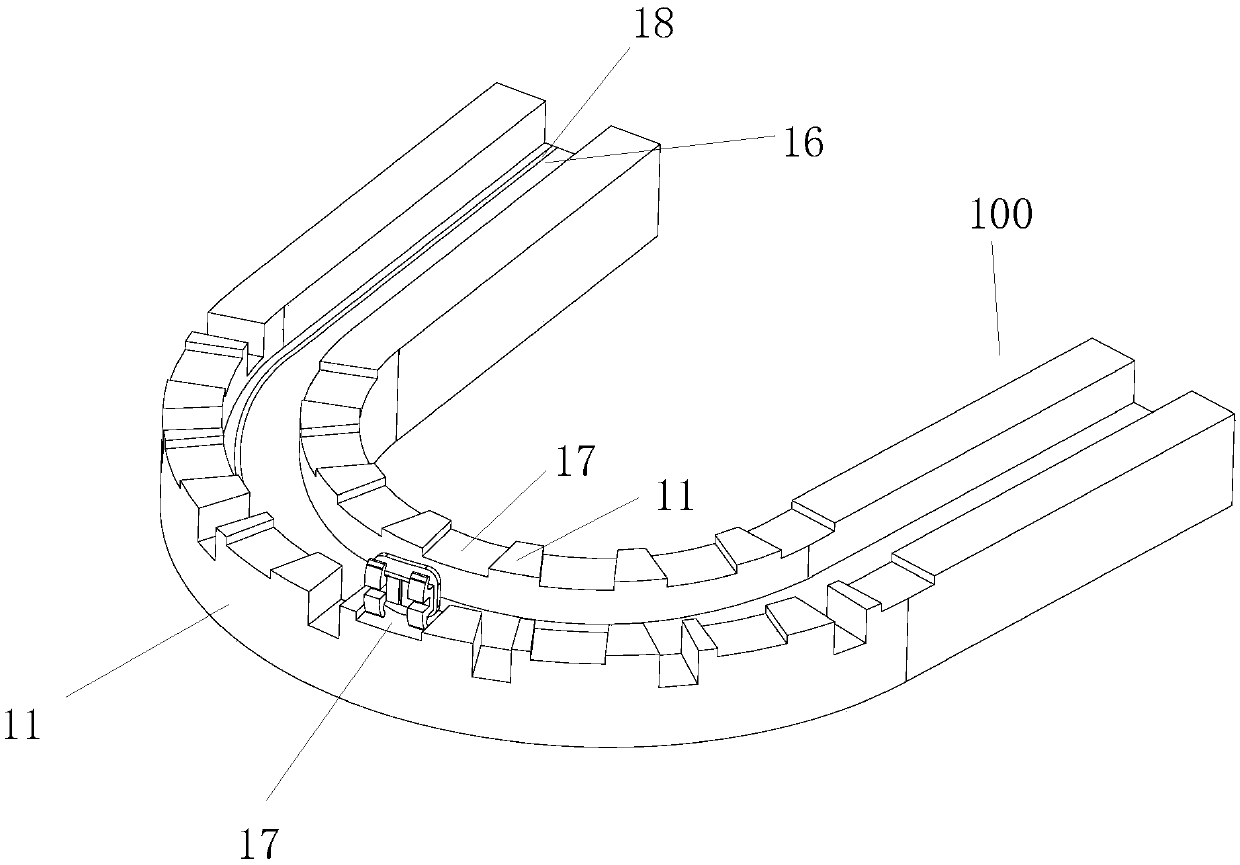

[0041] Such as figure 1 and Figure 4 As shown, the bracket positioning guide plate 100 includes an occlusal plate 16, the occlusal plate 16 is provided with a mounting plate 11 that fits the tooth surface, and the mounting plate 11 is provided with a matching opening 17 for holding the bracket. The number and position of the fitting openings 17 are adapted to the number and the position of the fitted tooth surface teeth. The mounting plate 11 fits on the inner surface or the outer surface of the teeth, and the mounting plate 11 is arranged on the outer edge or / and the inner edge of the occlusal plate 16 . Whether the mounting plate 11 fits on the inner edge or the outer edge of the tooth depends on whether the bracket is fixed on the outside or the inner side of the tooth, and the corresponding mounting plate 11 is also arranged on the inner edge or the outer edge of the occlusal plate 16 .

[0042] When the teeth of the upper and lower oral cavity all need to be corrected,...

Embodiment 2

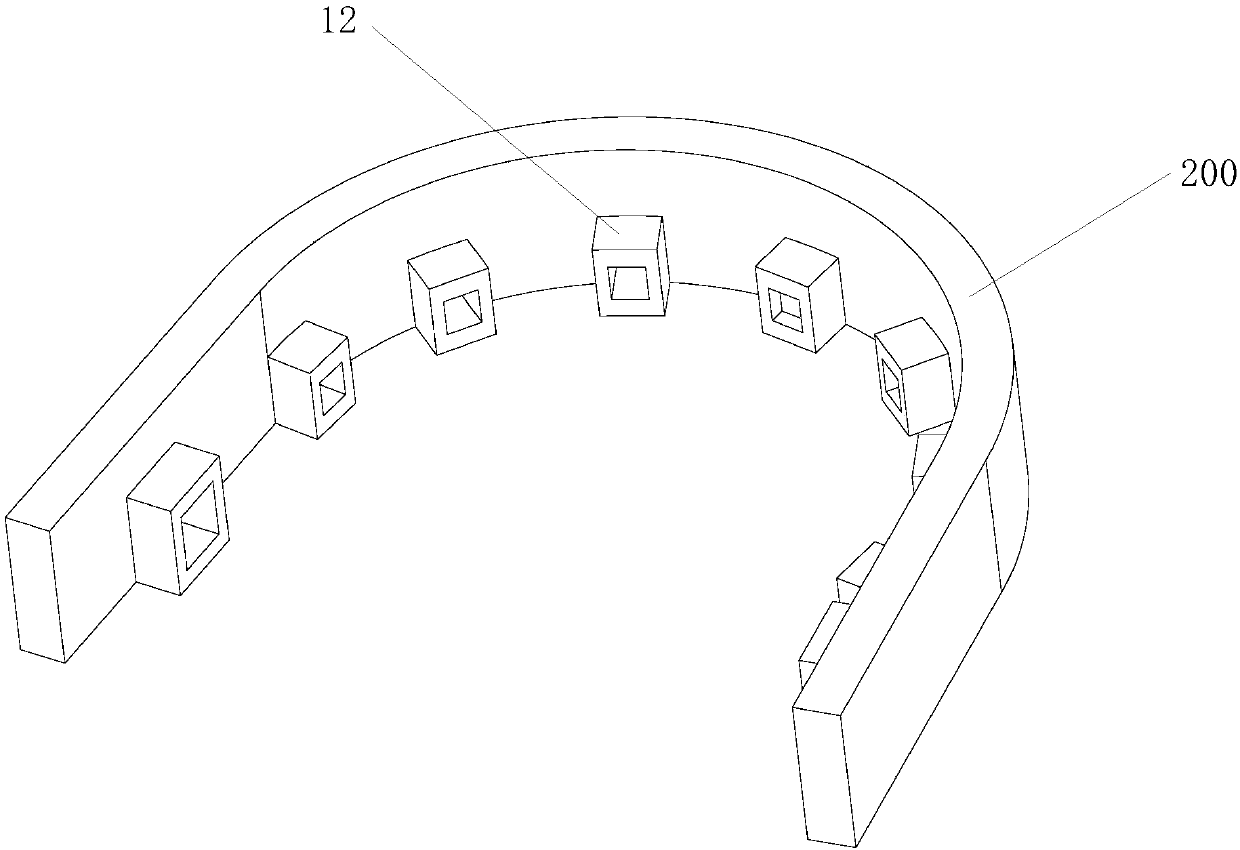

[0054] Such as Figure 1 to Figure 4 As shown, this embodiment discloses a bracket positioner, including the bracket positioning guide plate 100 in Embodiment 1, and also includes an acid-etched positioning plate 200. The shape of the acid-etched positioning plate 200 is similar to that of the mounting plate 11. Adaptation, 3D printing can also be used, and computer software can be used for computer simulation.

[0055] The biting acid etching device 12 is fixed on the outside of the acid etching positioning plate 200 , and the number and position of the acid etching device 12 are adapted to the number and position of the teeth along the acid etching positioning plate 200 . The acid-etching positioning plate 200 is arranged on the upper side of the occlusal base plate 10, and its degree of inclination and the curved track are adapted to the direction of the teeth that need to be treated. The bonding surface 110 of the acid-etching positioning plate 200 and the teeth is matche...

Embodiment 3

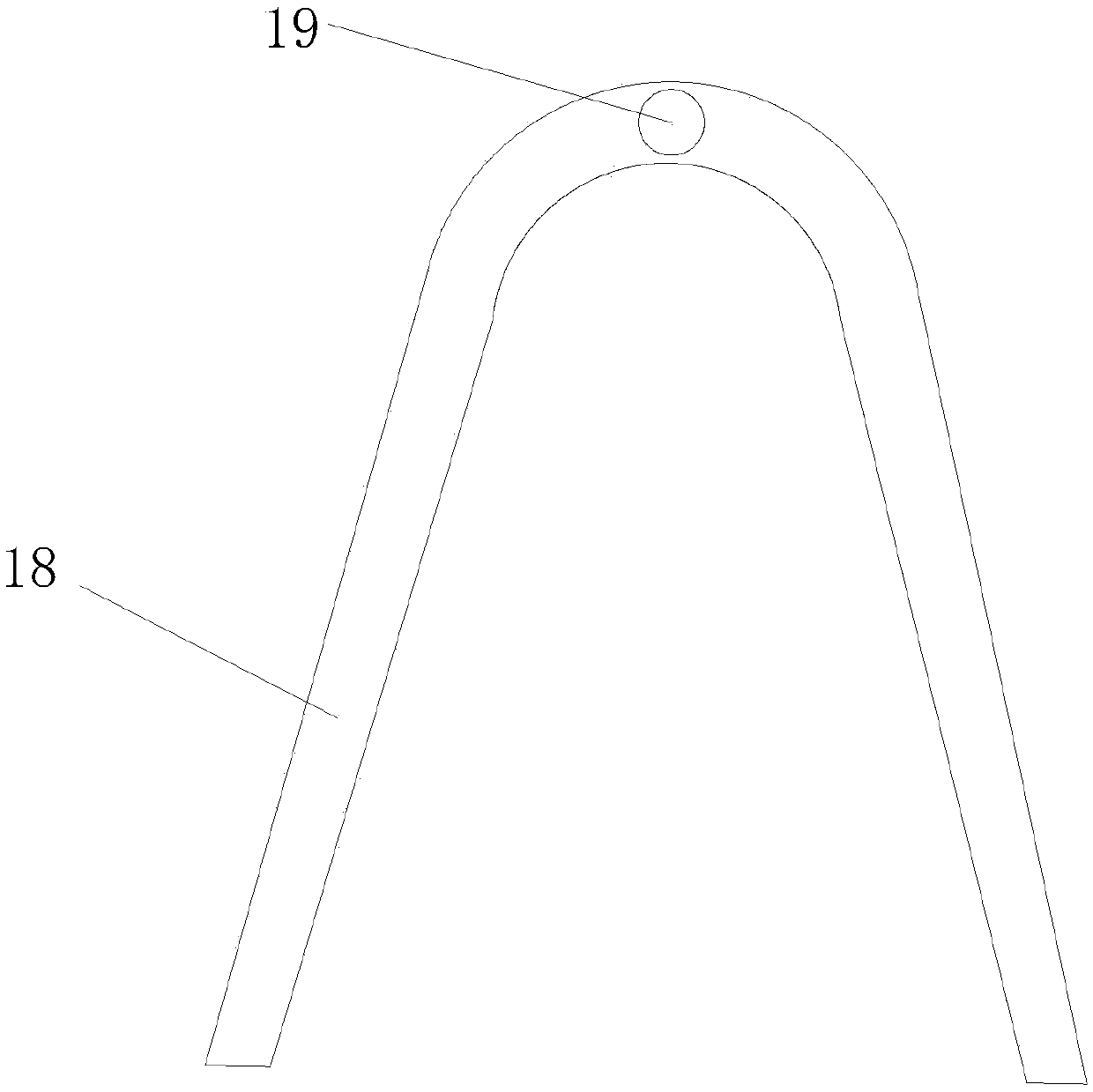

[0064] Such as image 3 As shown, this embodiment provides a structure of occlusal plate 16 suitable for embodiment 1 and embodiment 2. The upper end surface of occlusal plate 16 is provided with a diversion groove 18 for receiving acid etching liquid, and the diversion groove 18 is along the The trajectory of the plate 16 is set, and the diversion groove 18 is located directly below the acid etching device 12, and its purpose is not to affect the occlusal of the teeth. The depth of the diversion groove 18 is a tendency to gradually deepen toward the middle along the two ends of the diversion groove 18, and the middle part of the diversion groove 18 (that is, near the front teeth) is provided with a liquid accumulation port 19, and the edge of the diversion groove 18 is round. corner transition. Although the device adopts computer simulation to make the coordination very precise, basically there will be no phenomenon of acid etching liquid overflowing, but in the process of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com