Machined product spraying and drying treatment device

A drying treatment and mechanical processing technology, which is applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problems of poor treatment effect and affecting the quality of pretreatment, etc., and achieve convenient installation and low production cost , the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

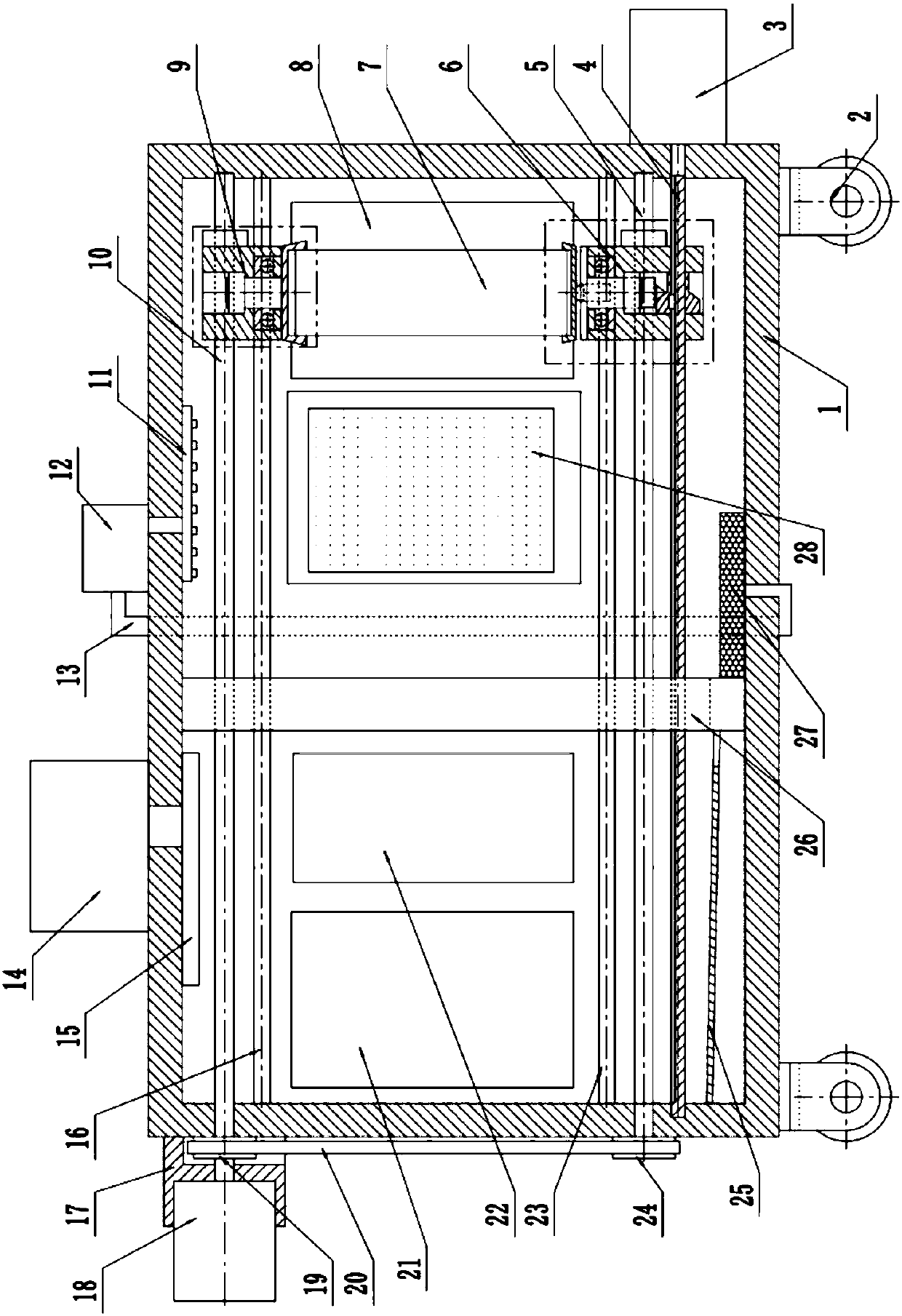

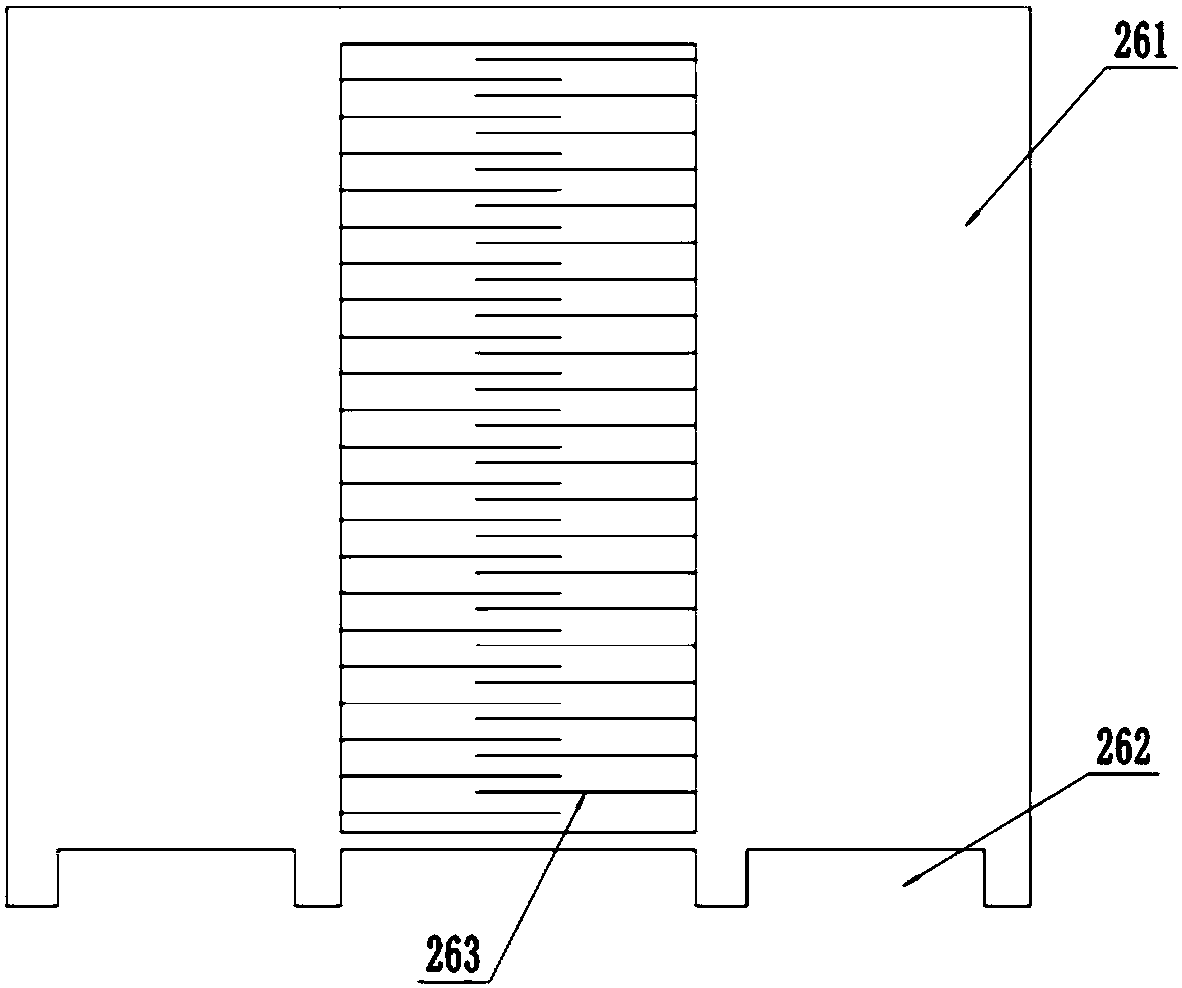

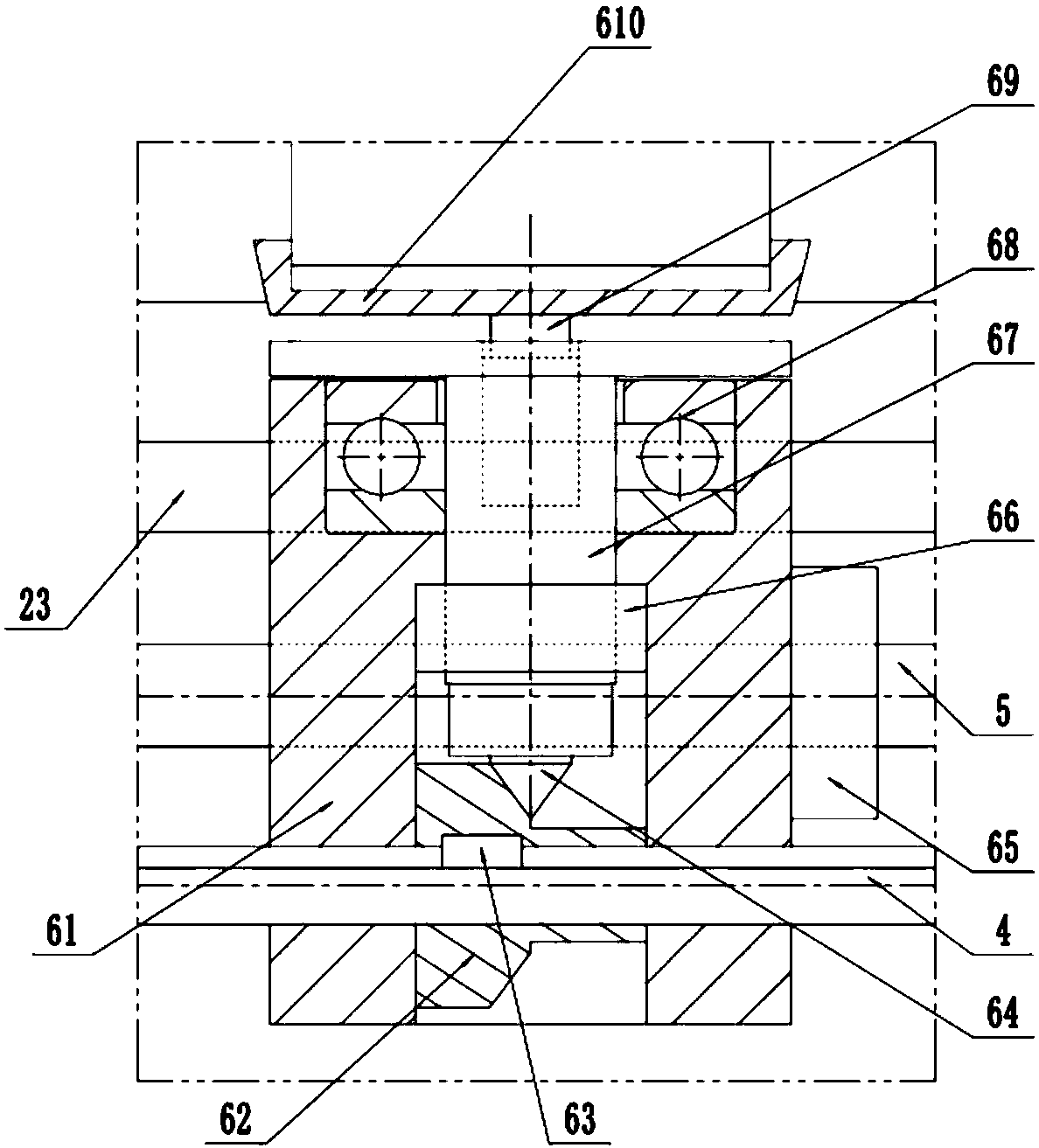

[0020] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: a spray drying treatment device for mechanically processed products, including a dryer 22, and also includes a housing 1, a universal wheel 2, a motor-3, a transmission shaft 4, and a screw-5 , clamping device one 6, workpiece 7, entrance door 8, clamping device two 9, screw rod two 10, nozzle 11, water pump 12, connecting pipe 13, exhaust fan 14, exhaust hood 15, upper guide post 16, fixed frame 17 , motor two 18, driving wheel 19, synchronous belt 20, outlet door 21, lower guide post 23, driven wheel 24, water guide plate 25, isolation plate 26, filter cover 27 and fixed rinse plate 28; Described housing 1 bottom Several universal wheels 2 are evenly arranged, and the lower side of the interior of the housing 1 is fixedly connected to the lower guide post 23, and the upper side of the interior of the housing 1 is fixedly connected to the upper guide post 16; There is a clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com