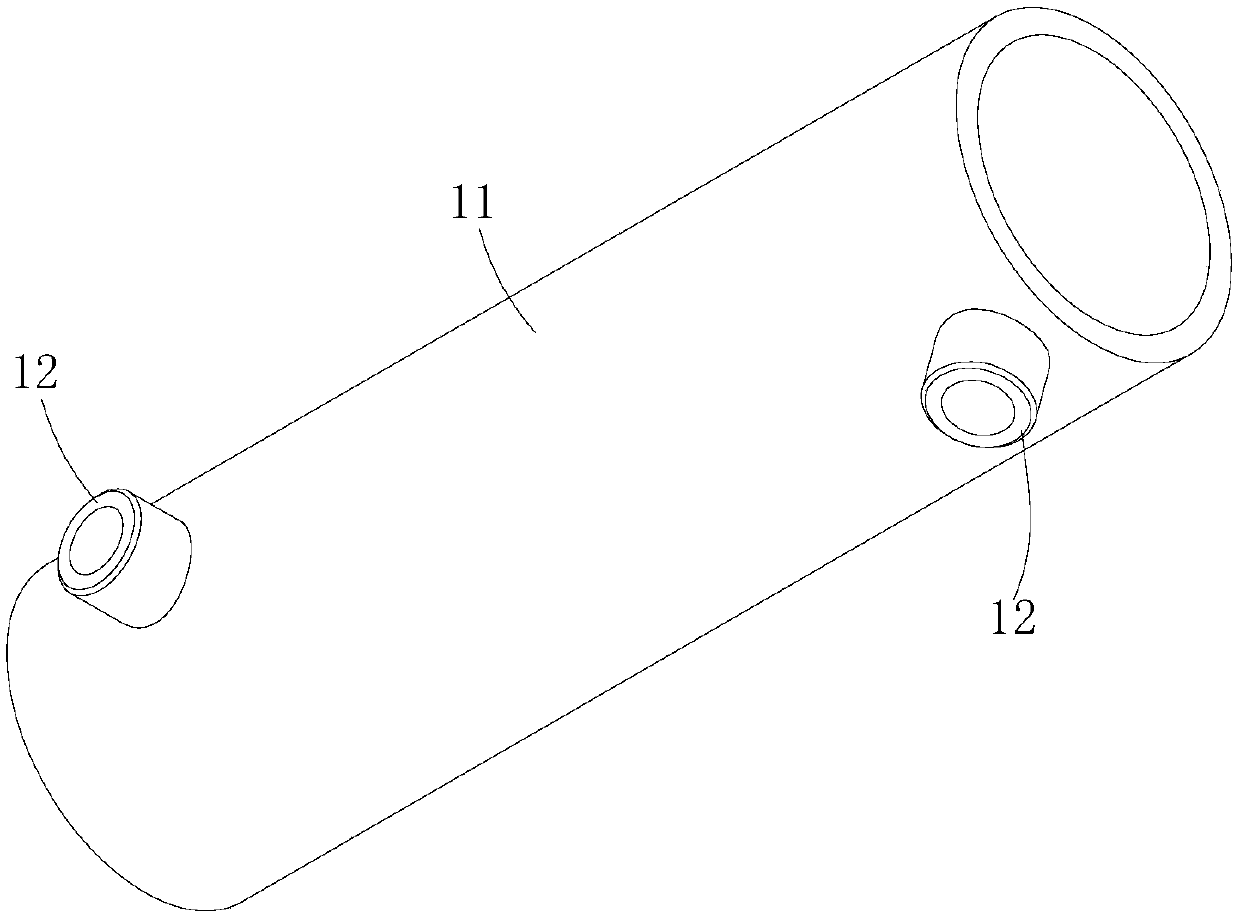

Oil hole drilling fixture for joint of inclined oil cylinder

A technology of tilting oil cylinders and drilling tooling, applied in the field of fixture tooling, can solve the problems of affecting the quality of oil holes, low manual positioning accuracy, poor coaxiality of the inner holes of oil hole joints, etc., and achieves the effect of stable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

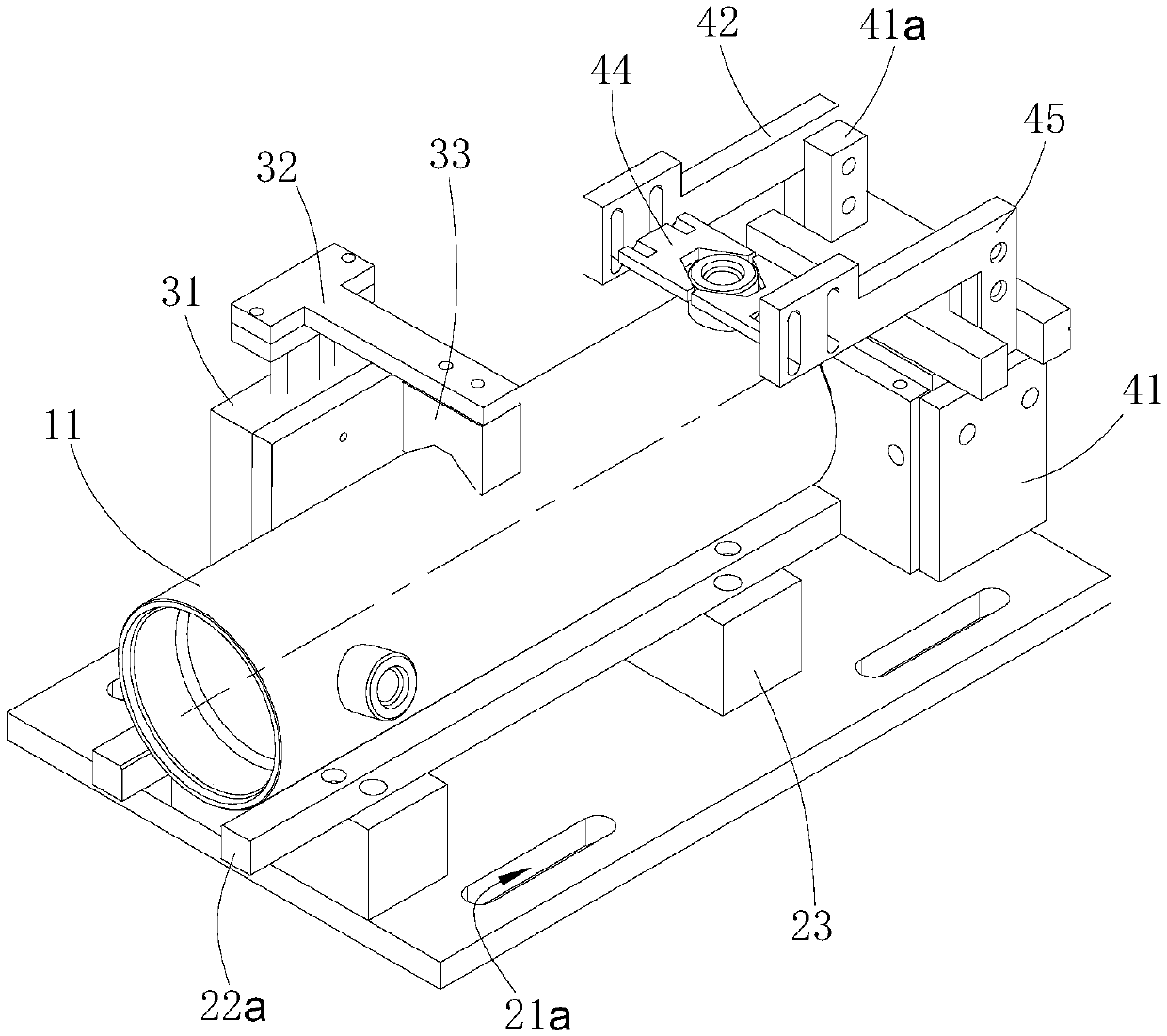

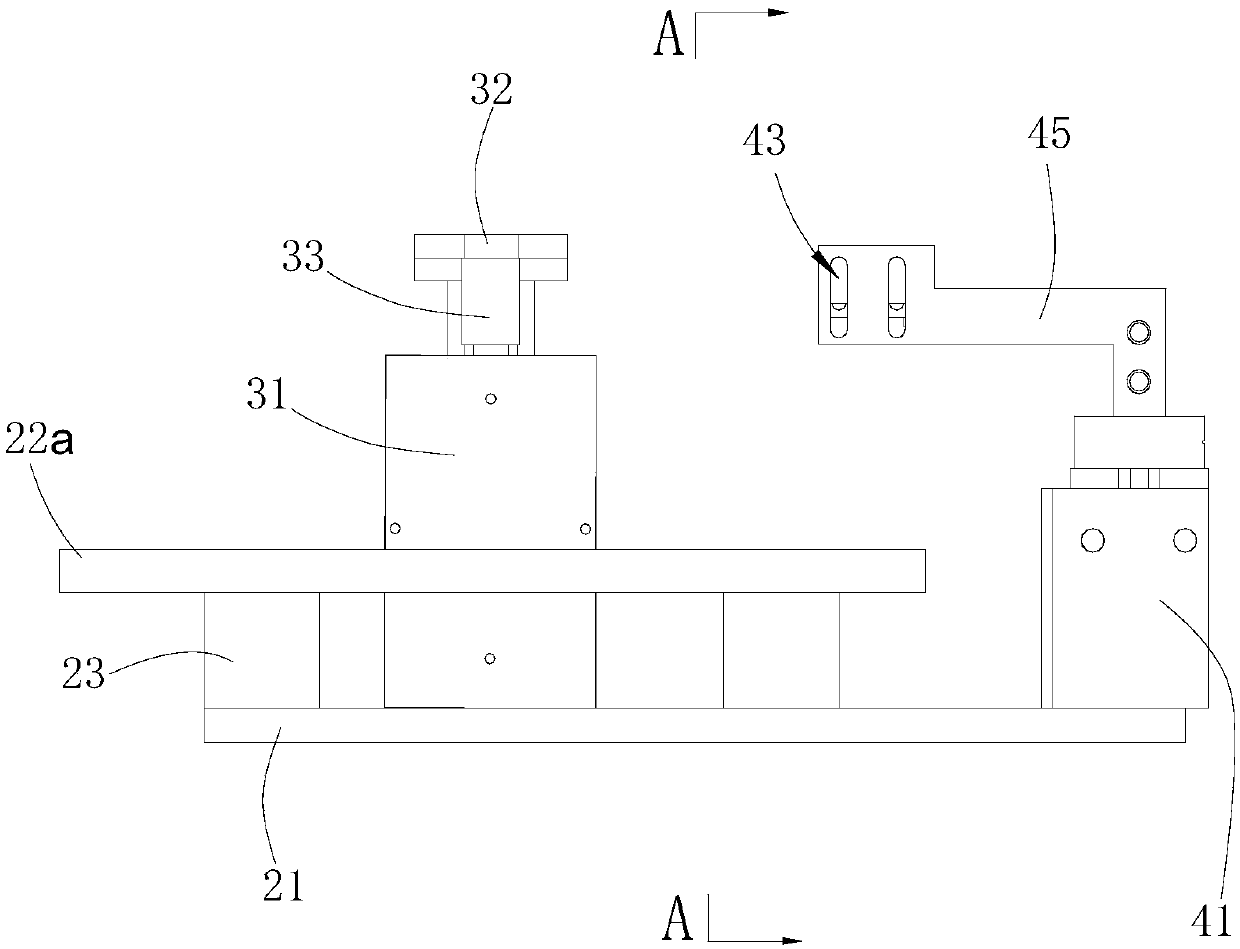

[0029] Such as Figures 2 to 5 shown

[0030] The tooling includes a base, a pressing component and a clamping component.

[0031] The base includes a base plate 21, a track and two backing plates 23, the track includes two slide rails 22a, the direction of the two slide rails 22a is left and right, and the two slide rails 22a are fixed on the base plate by two backing plates 23 21, the slide rail 22a, the backing plate 23 and the bottom plate 21 are fixed by bolt connectors, and the upper side of the track is provided with a space for placing the cylinder body 11 of the inclined cylinder, and the above-mentioned space constitutes the oil hole drilling of the joint 12 of the inclined cylinder. The station where the length direction of the inclined cylinder body 11 is placed is consistent with the direction of the slide rail 22a. There are four connection holes 21a fixed on the bottom plate 21, each connection hole 21a is a waist-shaped hole, and the four connections The leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com