Urban rail metro vehicle ceiling trim lifting structure

A hoisting and ceiling technology, which is applied in the direction of railway vehicle lighting, railway vehicle heating/cooling, railway roof, etc., to achieve the effects of reducing weight, saving manpower and material resources, and simplifying the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

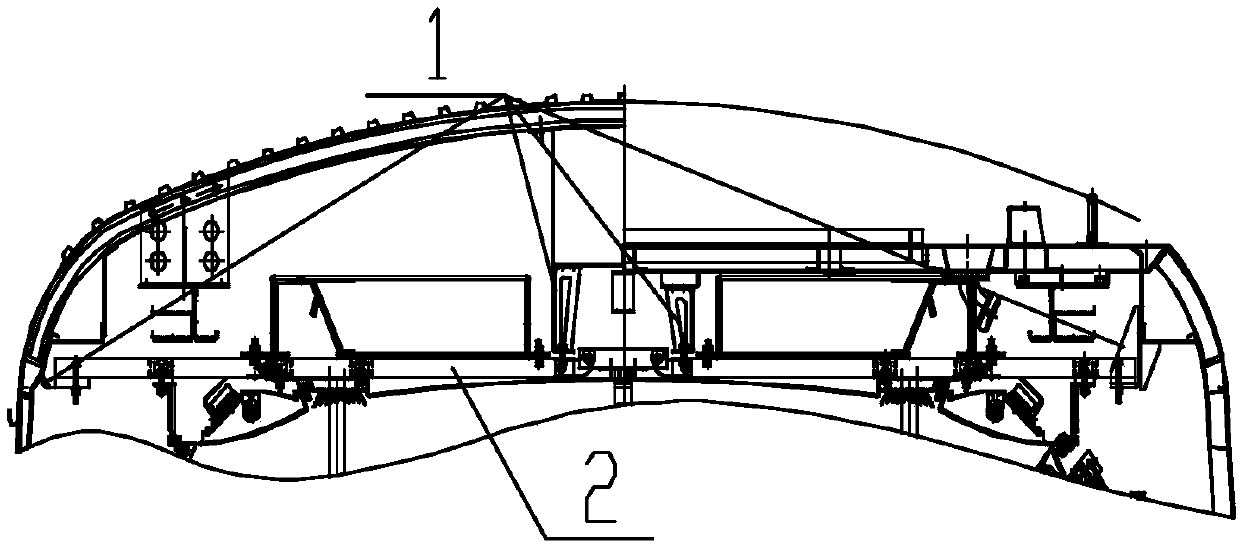

[0026] The present invention will be further described below in conjunction with the drawings.

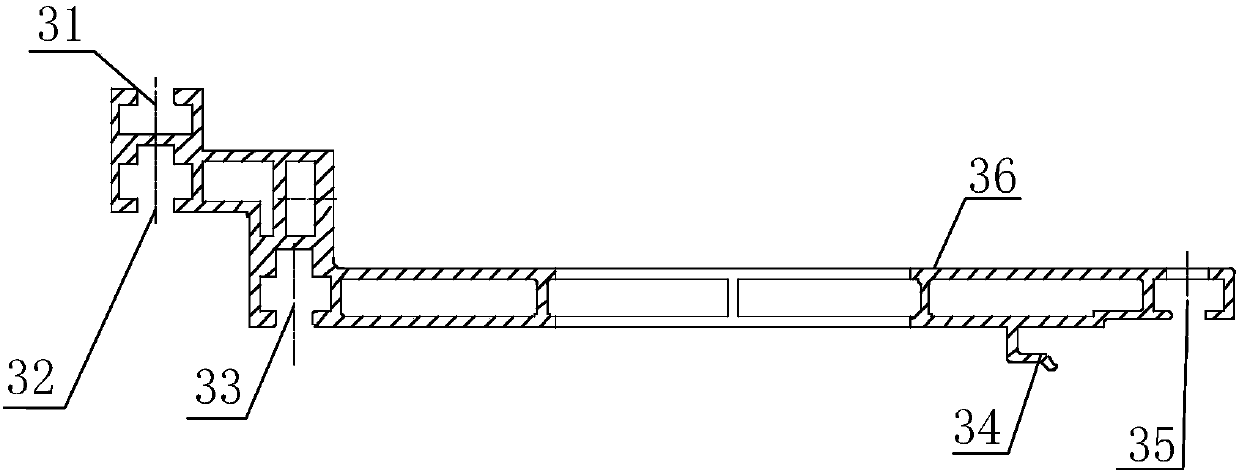

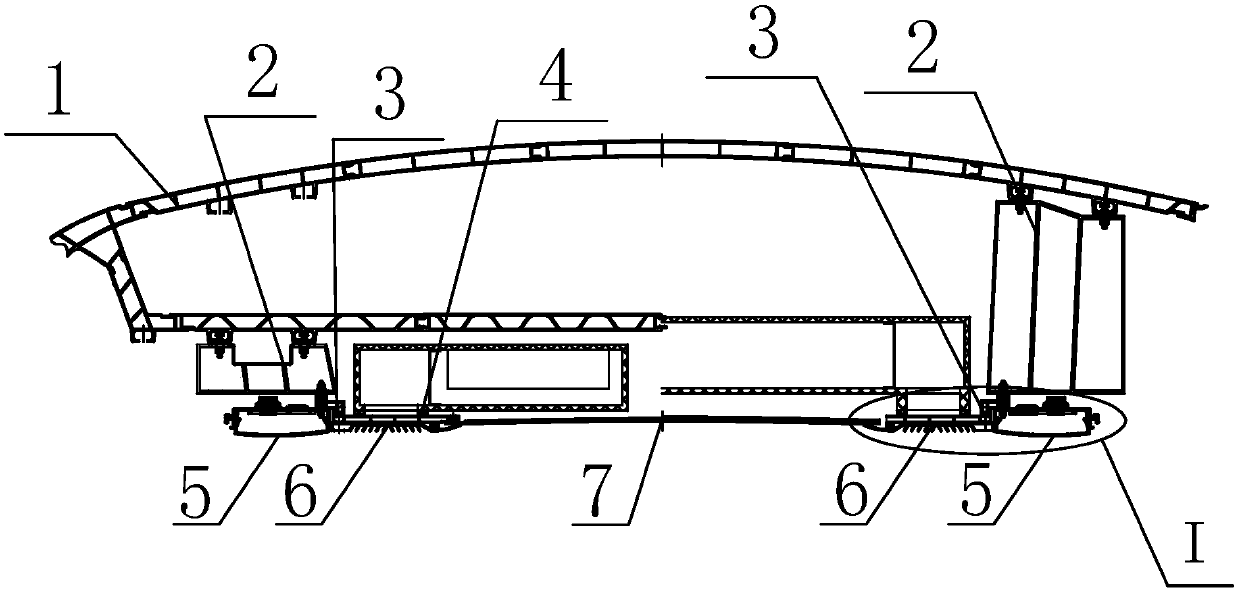

[0027] Such as figure 2 As shown, the upper part of the hoisting structure is designed with a C-shaped installation chute for fixing the hoisting structure, and a chute is designed at the bottom left to install one side of the lamp 5; the lower plane of the hoisting profile 3 is designed with a chute and a chute for the grille 6. The slot is used to install the grille 6; a chute is designed at the end of the profile cantilever to install the middle roof. Because the lifting profile 3 is arranged long and the installation chute is long, the installation points of the top plate 7 and the grille 6 can be arranged arbitrarily according to actual conditions.

[0028] The hoisting profile 3 is arranged in the length direction of the vehicle, and the air outlet is directly crimped on the hoisting profile 3. As there is no obstacle in the length direction of the vehicle, the air outlet can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com