Self-supervision method and control system of explosion-proof forklift

A technology of control system and forklift, which is applied in the direction of hoisting device, lifting equipment safety device, etc., can solve the problems of immature technology and strengthening forklift, and achieve the effect of ensuring safe operation, high reliability and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

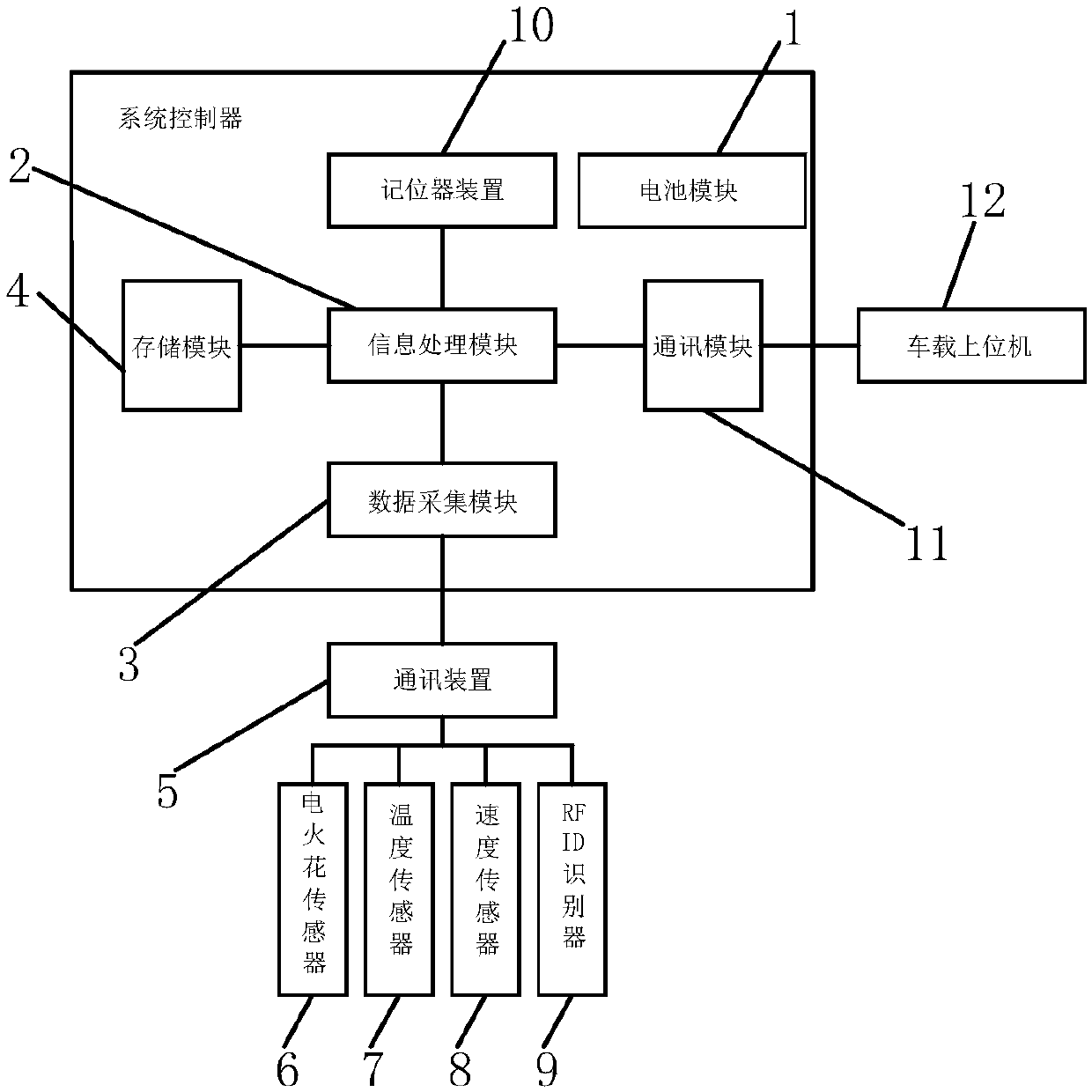

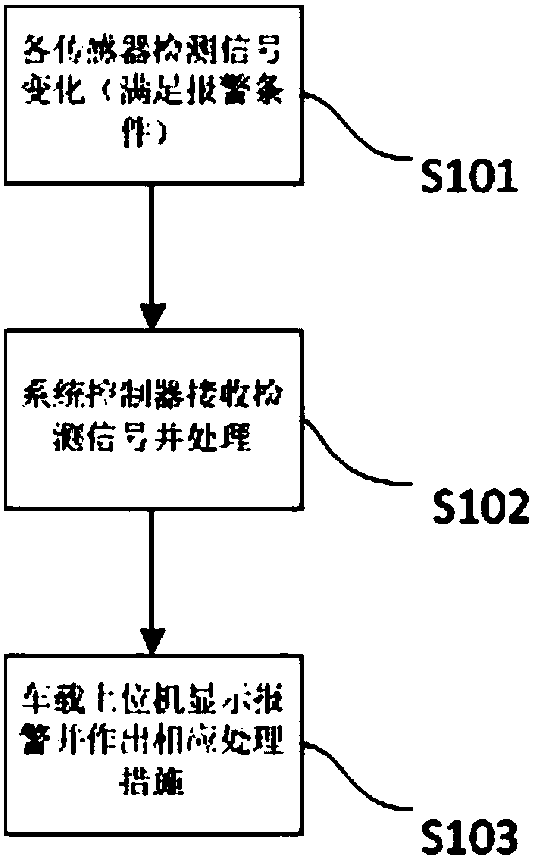

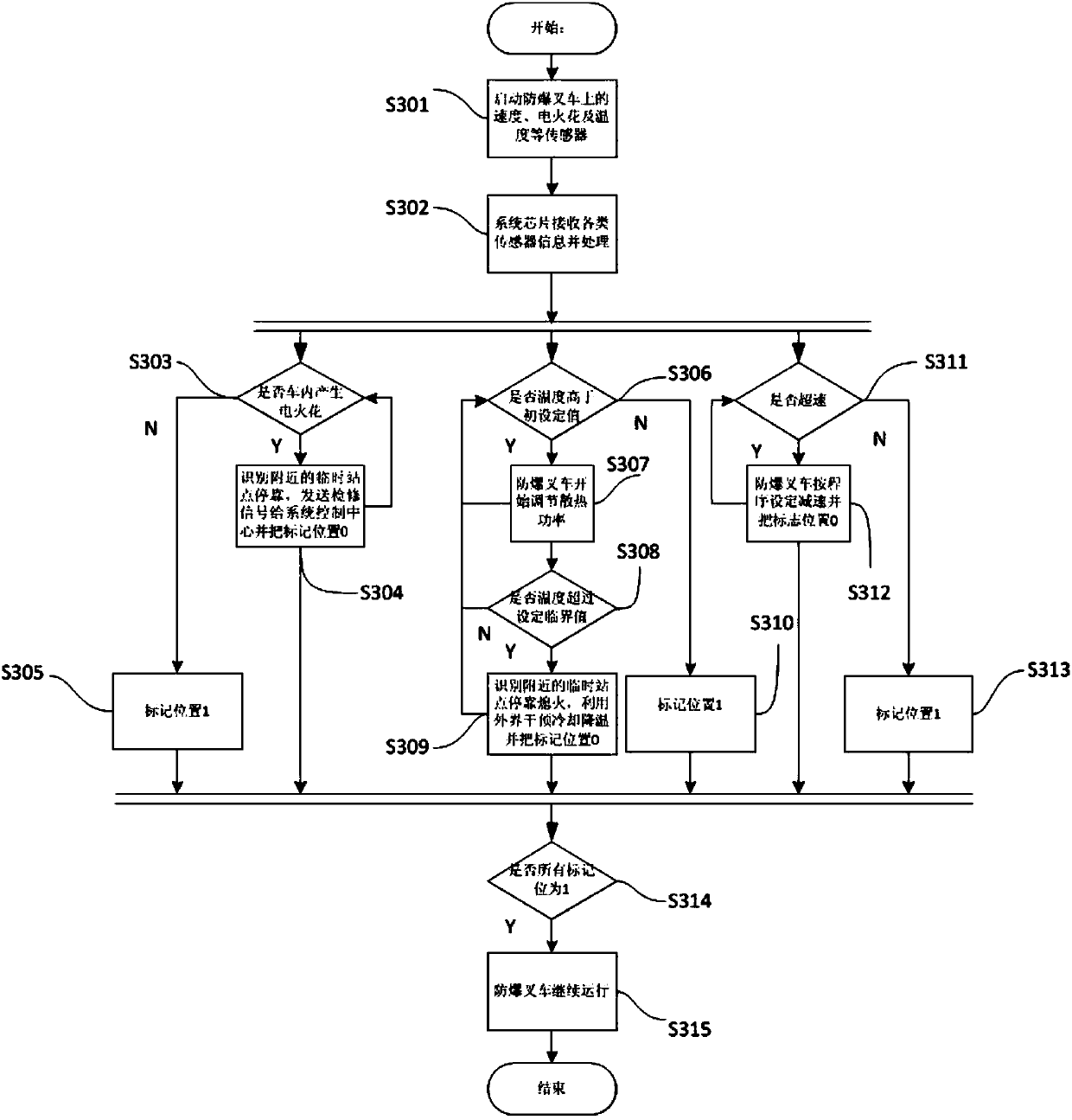

[0041] Embodiment 1. Explosion-proof forklift control system, such as figure 1 As shown, it includes a sensor, an RFID identifier 9, a system controller, and a vehicle-mounted upper computer 12.

[0042] The sensors include a speed sensor 8, a temperature sensor 7 and an electric spark sensor 6. The speed sensor 8 is used to detect whether the explosion-proof forklift is overspeed and generates a speed signal; the temperature sensor 7 is used to detect whether the temperature exceeds the standard and generates a temperature signal; the electric spark sensor 6 It is used to detect whether electric spark is generated inside and generate electric spark signal.

[0043] The system controller receives and processes the detection signals of the speed sensor 8, the temperature sensor 7 and the electric spark sensor 6, and generates an alarm signal to send to the on-board host computer 12. The system controller includes an information processing module 2, a storage module 4, a battery modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com