Nickel saving type 7Ni steel for ultralow temperature environment and heat treatment technology of nickel saving type 7Ni steel

An ultra-low temperature, nickel-saving technology, applied in the field of low-temperature steel, to achieve the effect of uniform distribution and dispersion of reversed austenite, fine structure, and saving Ni resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

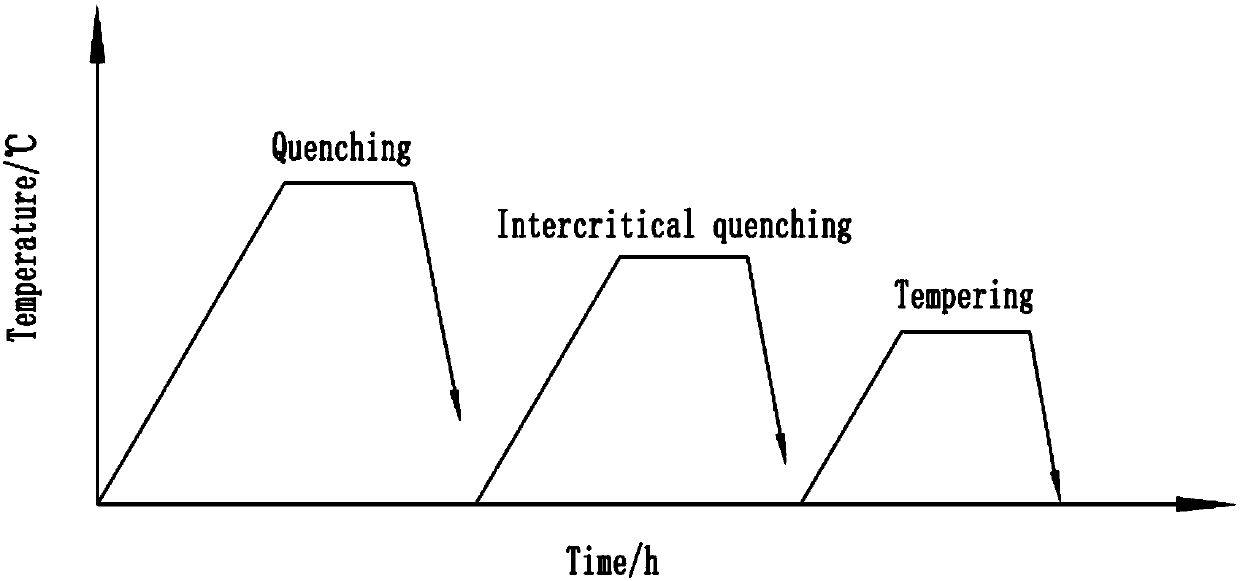

[0038] A nickel-saving 7Ni steel used in ultra-low temperature environments. The chemical composition of the nickel-saving 7Ni steel is as follows: Ni: 7.00-7.60%, C: 0.02-0.06%, Si: 0.03-0.06%, Mn : 0.70~0.90%, P≤0.010%, S≤0.005%, Cr: 0.30~0.60%, Nb: 0.01~0.03%; the balance is Fe (one of the specific components is shown in Table 1); smelting according to the above ratio , adopt corresponding desulfurization technology to control the impurity content; after that, carry out multi-step hot rolling on the cast ingot and then air cooling, and before finishing rolling, the thickness of the intermediate billet should be between 70 and 100mm; the rolled steel after air cooling should be subjected to QLT heat treatment ( Process parameters are shown in Table 2), such as figure 1 As shown, samples were taken from the steel plate after heat treatment, and the microstructure of the sample was observed with a scanning electron microscope. The specific microstructure is as follows figure...

Embodiment 2

[0040] A nickel-saving 7Ni steel used in ultra-low temperature environments. The chemical composition of the nickel-saving 7Ni steel is as follows: Ni: 7.00-7.60%, C: 0.02-0.10%, Si: 0.50-0.80%, Mn : 0.10~0.30%, P≤0.010%, S≤0.005%, Cr: 0.30~0.60%, Mo: 0.10~0.20%; the balance is Fe (one of the specific components is shown in Table 1); smelting according to the above ratio , adopt corresponding desulfurization technology to control the impurity content; after that, carry out multi-step hot rolling on the cast ingot and then air cooling, and before finishing rolling, the thickness of the intermediate billet should be between 70 and 100mm; the rolled steel after air cooling should be subjected to QLT heat treatment ( Process parameters are shown in Table 2), such as figure 1 As shown, samples were taken from the steel plate after heat treatment, and the microstructure of the sample was observed with a scanning electron microscope. The specific microstructure is as follows image ...

Embodiment 3

[0042] A nickel-saving 7Ni steel used in ultra-low temperature environments. The chemical composition of the nickel-saving 7Ni steel is as follows: Ni: 7.00-7.60%, C: 0.02-0.10%, Si: 0.50-0.80%, Mn : 0.10~0.30%, P≤0.010%, S≤0.005%, Cr: 0.30~0.60%, Mo: 0.10~0.20%, Nb: 0.03~0.06%; the balance is Fe (one of the specific components is shown in Table 1 ). Smelting according to the above ratio of ingredients, adopting corresponding desulfurization technology to control the impurity content; after that, the ingot is subjected to multi-step hot rolling and then air-cooled. The steel is subjected to QLT heat treatment (process parameters are shown in Table 2), such as figure 1 As shown, samples were taken from the steel plate after heat treatment, and the microstructure of the sample was observed with a scanning electron microscope. The specific microstructure is as follows Figure 4 shown.

[0043] The chemical composition of 7Ni steel smelted in Example 1-3 of Table 1 and its comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com