Melt spinning machine

A spinning machine and spinning technology, used in melt spinning, filament generation, textiles and papermaking, etc., can solve the problems of complex operation, single state, low efficiency, etc., and achieve the effect of enriching effective data and diversifying types.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

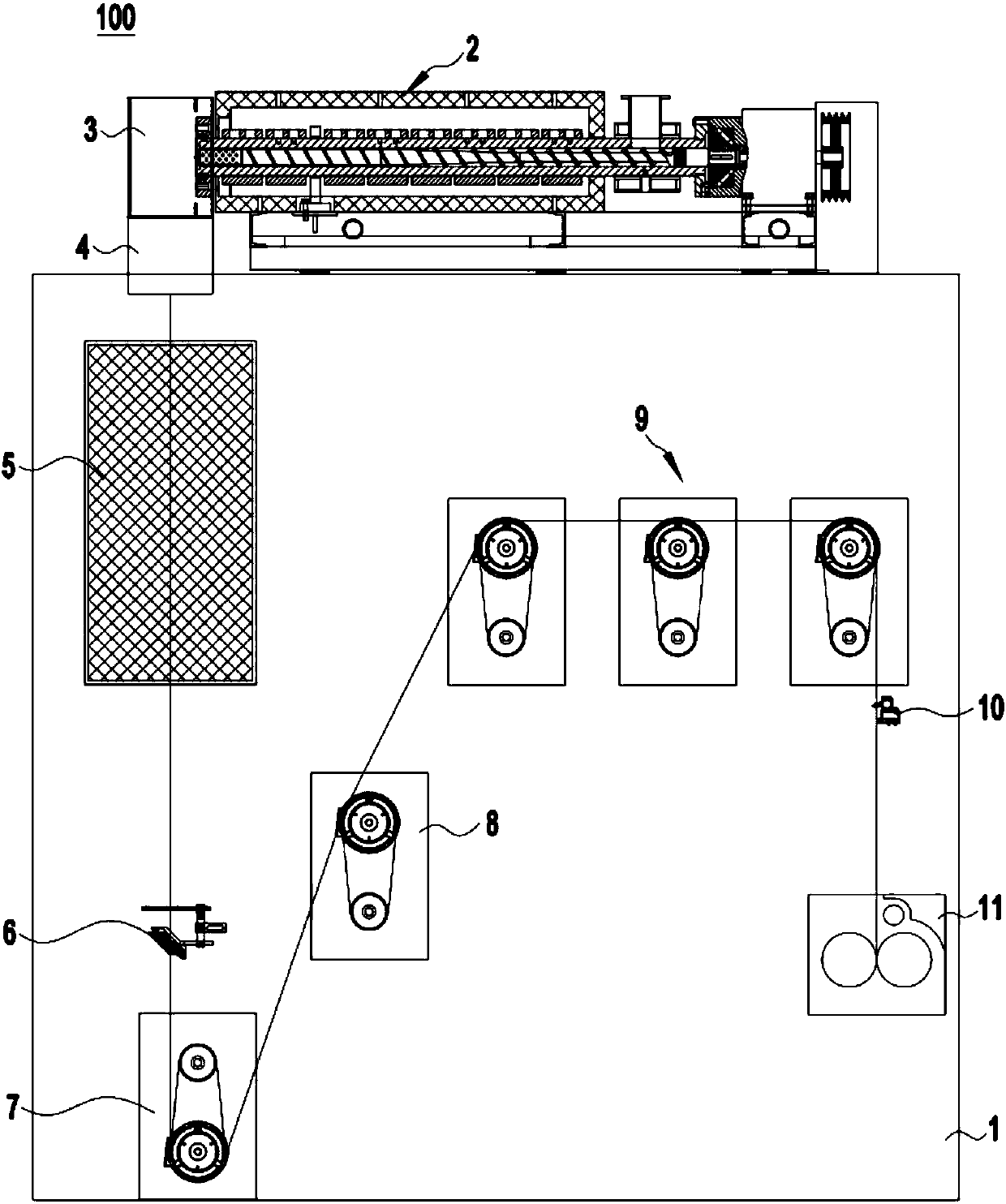

[0017] In order to describe the technical content, structural features, achieved goals and effects of the invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings. Among them, the "up", "down", "left", and "right" mentioned in this embodiment refer to the attached figure 1 up, down, left, and right directions shown in .

[0018] as attached figure 1 As shown, it is a schematic structural diagram of a melt spinning machine. The melt spinning machine 100 includes a frame 1, a melt extrusion mechanism 2, a metering mechanism 3, a spinning mechanism 4, a cooling mechanism 5, a wire adjustment mechanism 6, a A guide plate mechanism 7, a second guide plate mechanism 8, a third guide plate mechanism 9, a wire guide mechanism 10 and a winding mechanism 11, wherein the melt extrusion mechanism 2 is a plastic extruder, and the plastic extruder includes The barrel is equipped with an extruding screw rotating inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com