Flap-type intercepting well

An interception well and flap-type technology, applied to waterway systems, drainage structures, water supply devices, etc., can solve problems such as failure, poor operability, and unstable operation, and achieve less spare parts, strong adaptability, and low failure rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

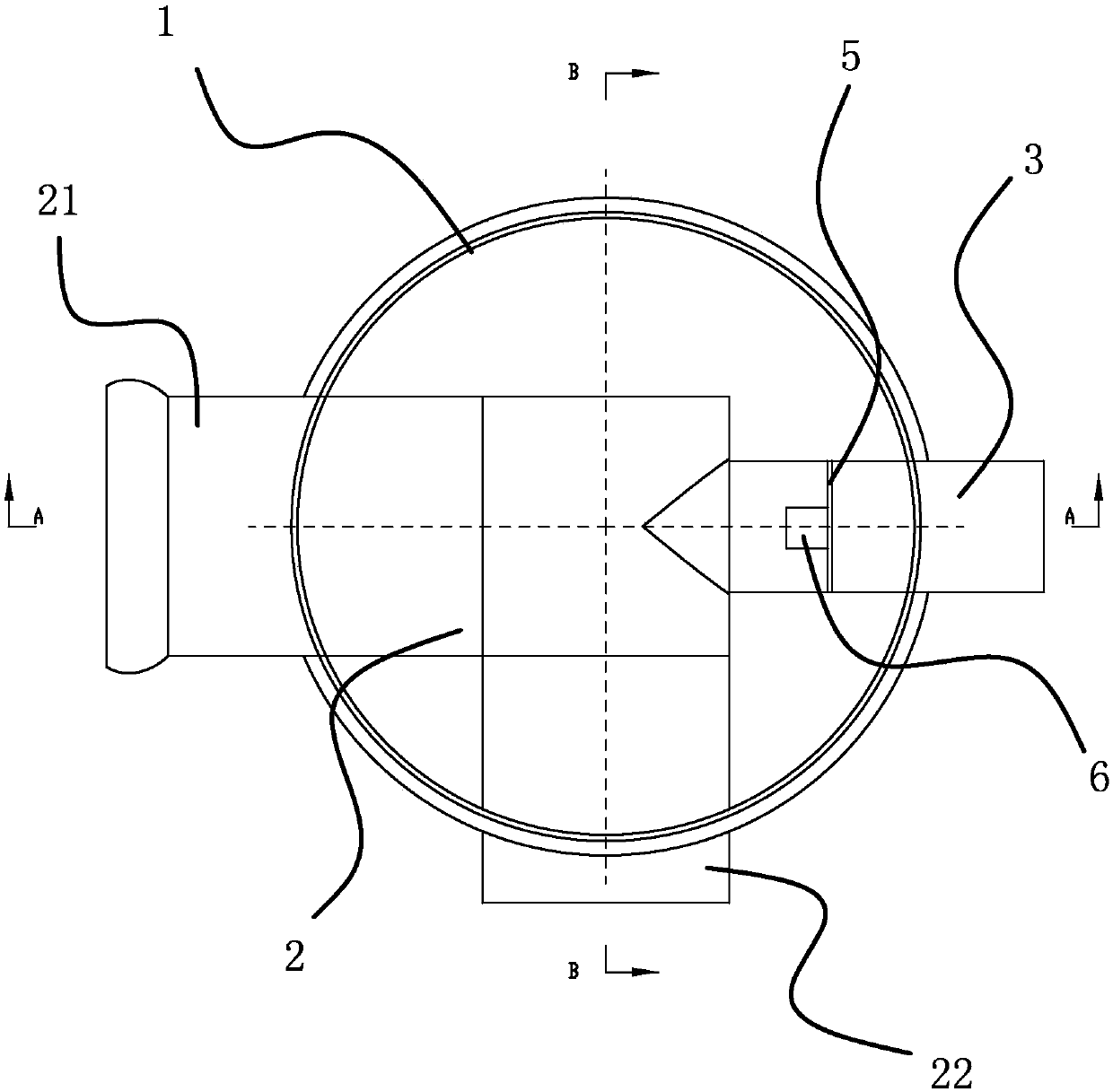

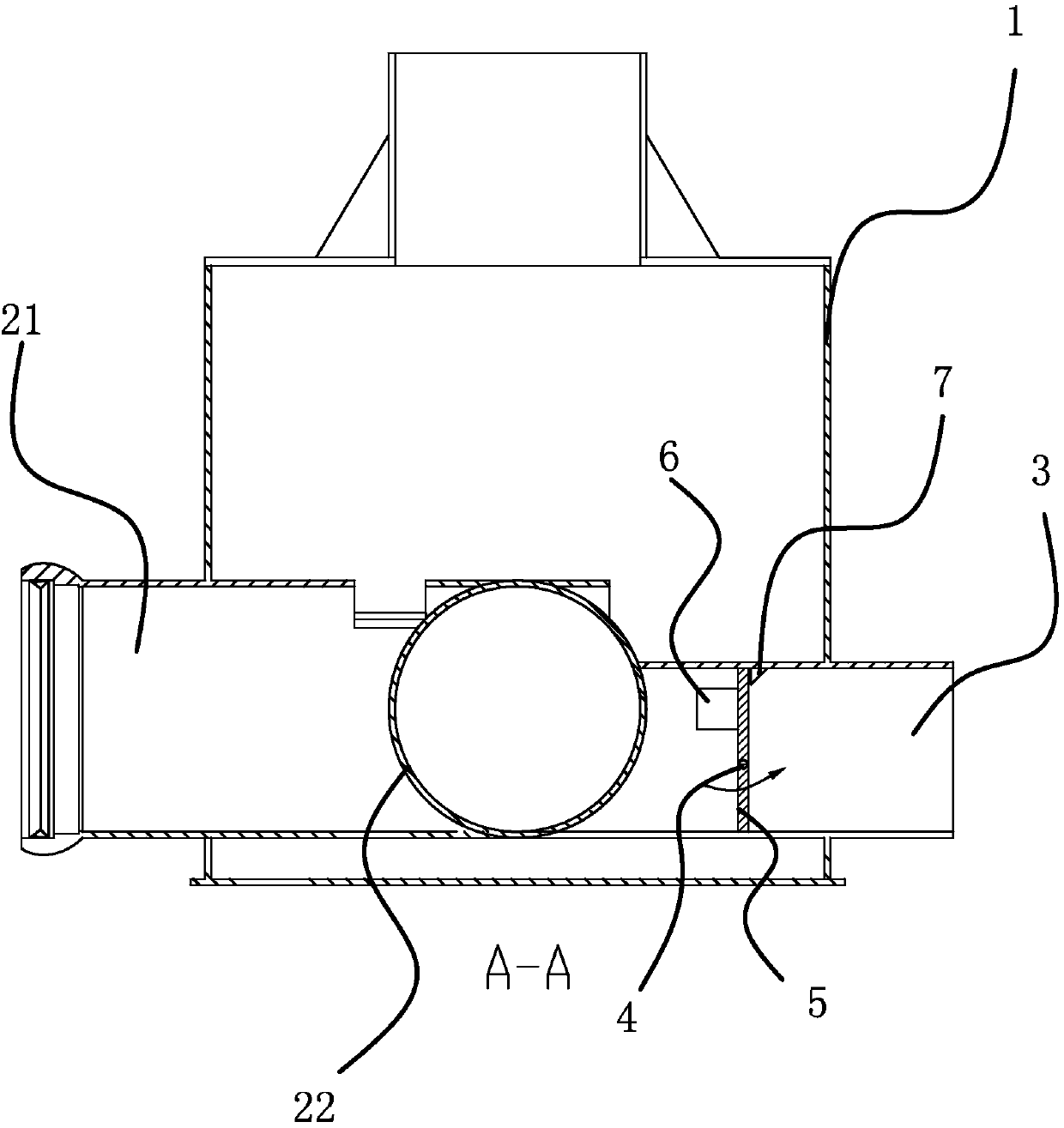

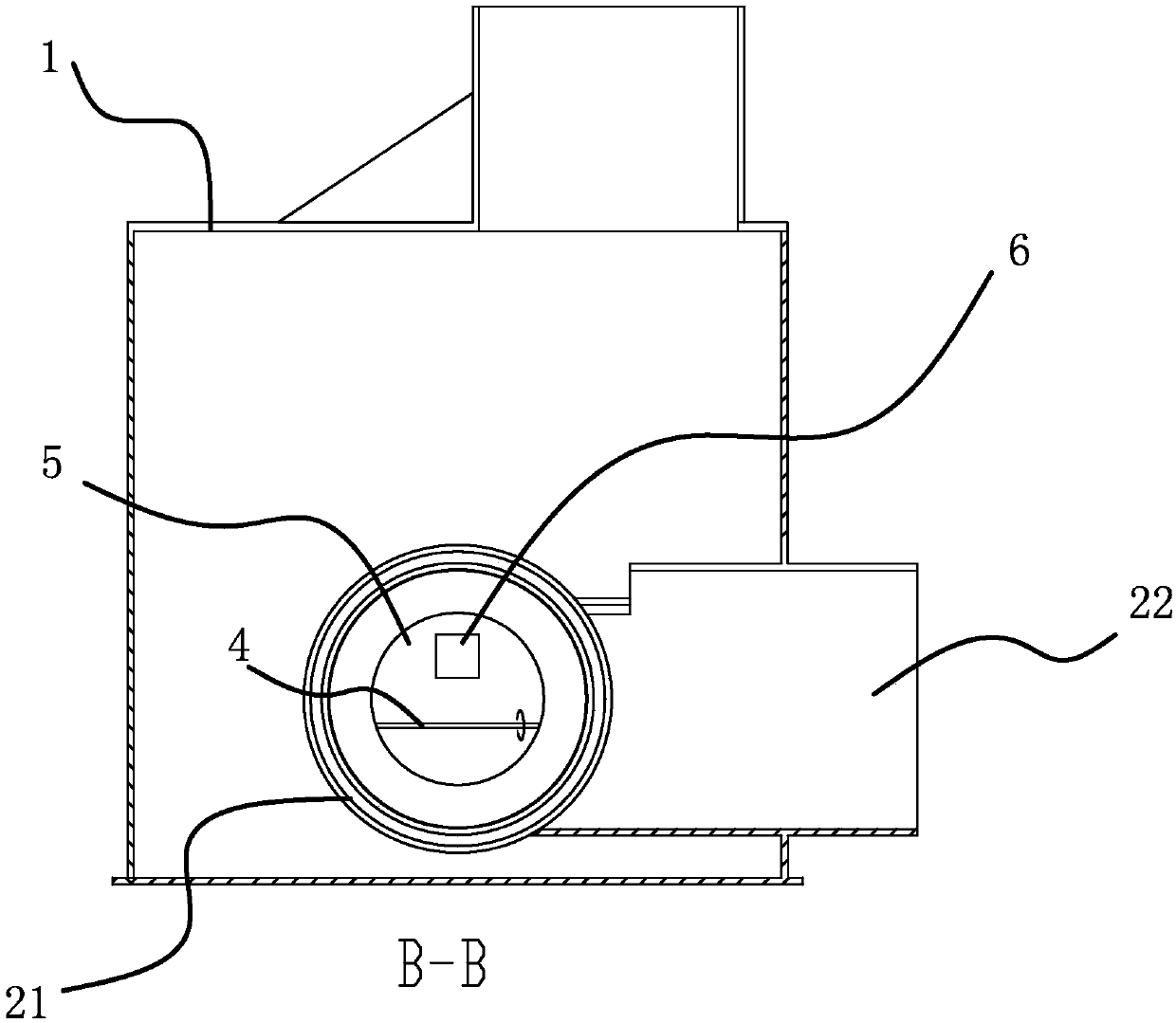

[0020] like figure 1 , figure 2 , image 3 As shown, the flap type intercepting well includes a vertically arranged inspection well 1, a bent drainage pipe 2 horizontally interspersed in the inspection shaft 1, and a straight intercepting pipe 3 communicating with the drainage pipe 2. The cutoff pipe 3 is provided with a cutoff assembly, the cutoff assembly includes a horizontally arranged rotating shaft 4 and a vertically arranged cutoff plate 5, the cutoff plate 5 is rotatably connected around the rotating shaft 4, and the cutoff plate 5 faces one end surface of the drainage pipe 2 As the front, the front of the cutoff plate 5 is fixed with a counterweight 6 , and the cutoff tube 3 is provided with a limit block 7 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com