Laminated wall structure and manufacturing method thereof

A wall structure and wall technology, applied in the direction of structural elements, walls, building components, etc., can solve the problems of low internal connection structure strength and poor integrity, and achieve high-efficiency, high-quality production, structural strength and overall performance enhancement, and ensure the structure. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

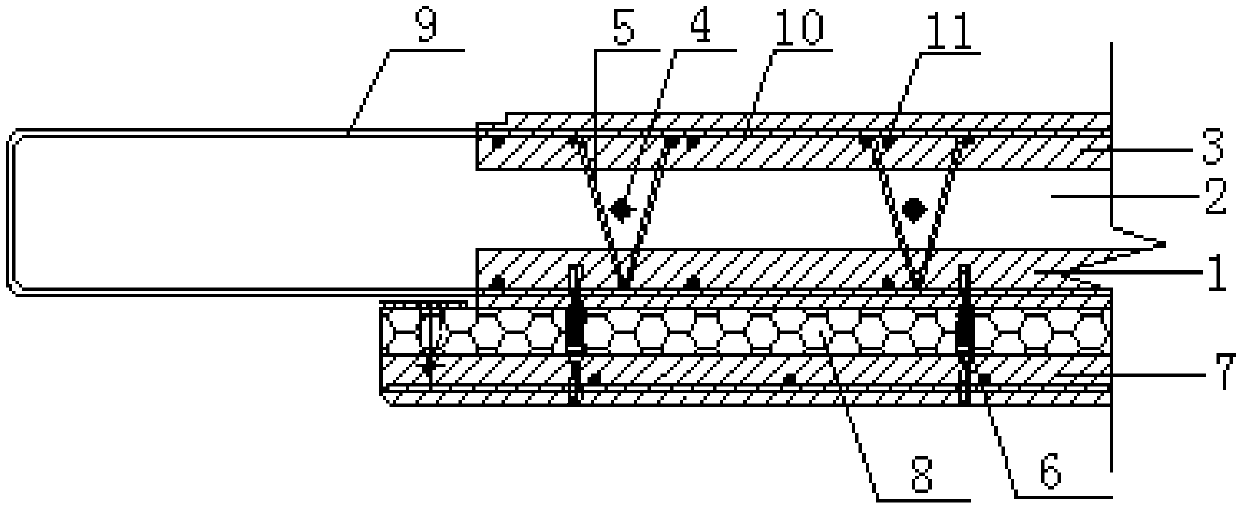

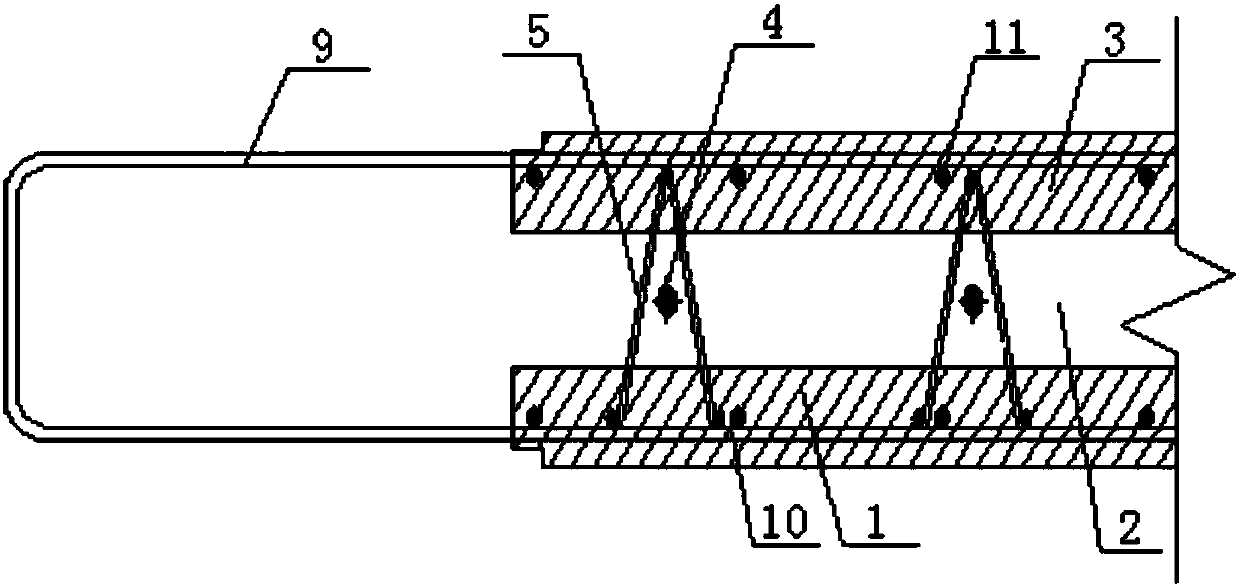

[0032] The laminated wall structure of the present invention and its manufacturing method include sequentially connected prefabricated exterior wall panels, intermediate cast-in-place layers and prefabricated interior wall panels, in which the prefabricated exterior wall panels, intermediate cast-in-place layers and prefabricated interior wall panels There are pre-buried square stirrups bridging the prefabricated outer wall panels, the middle cast-in-place layer and the prefabricated inner wall panels; In the wall panel, the middle part of the truss stirrup is bridged in the middle cast-in-place layer; the truss stirrup is divided into multiple rows, and each row is evenly distributed in the laminated wall from top to bottom, and each truss stirrup The plane of the reinforcement is arranged horizontally, the plane of the truss stirrup is perpendicular to the vertical plane of the superimposed wall; the prefabricated outer wall panel is a prefabricated outer leaf plate, the pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com