A method and device for calculating the leakage rate of a check valve

A check valve and leakage rate technology, applied in the field of automatic control, can solve the problems of meaningless check valve results and achieve the effect of avoiding negative values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

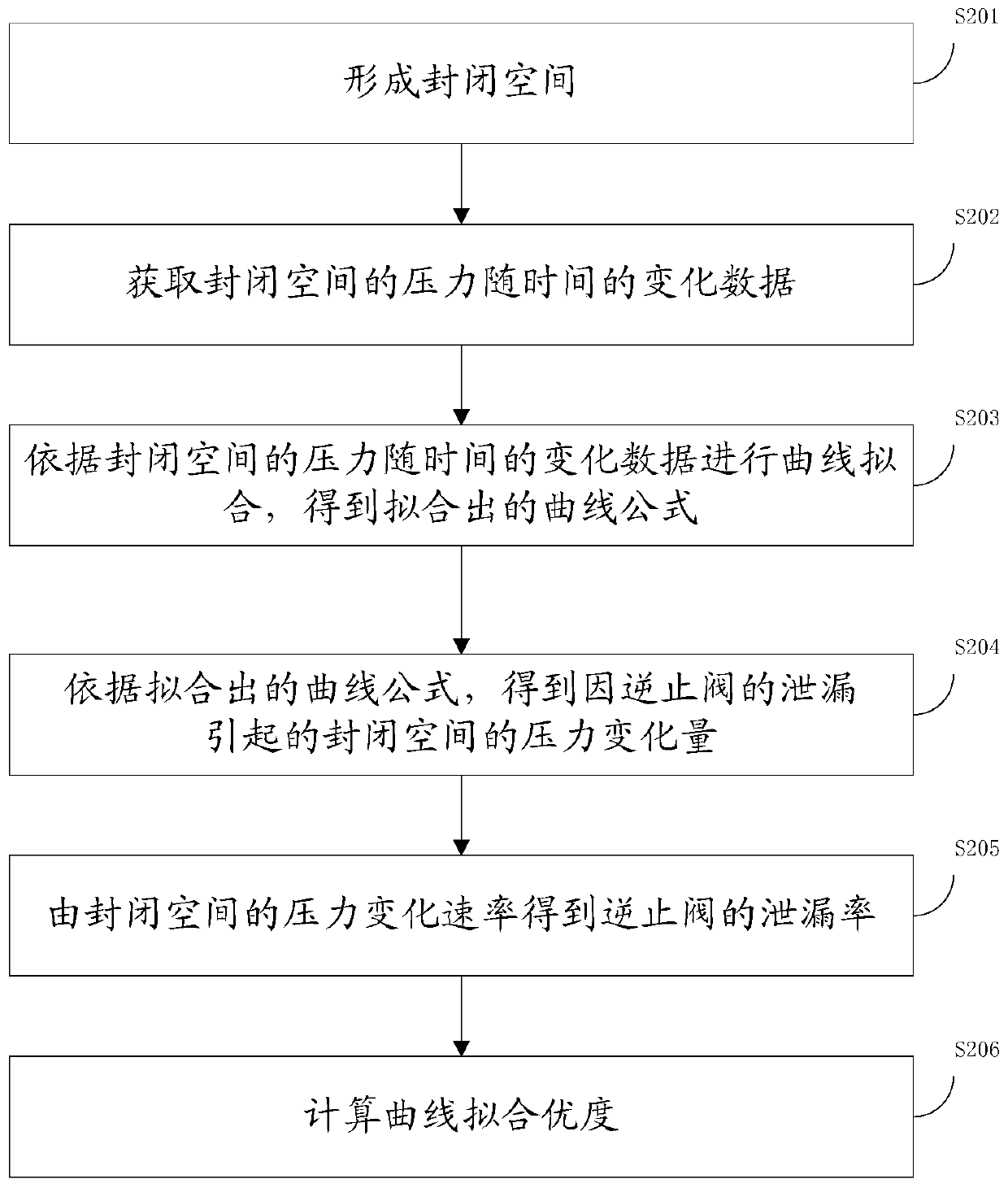

Method used

Image

Examples

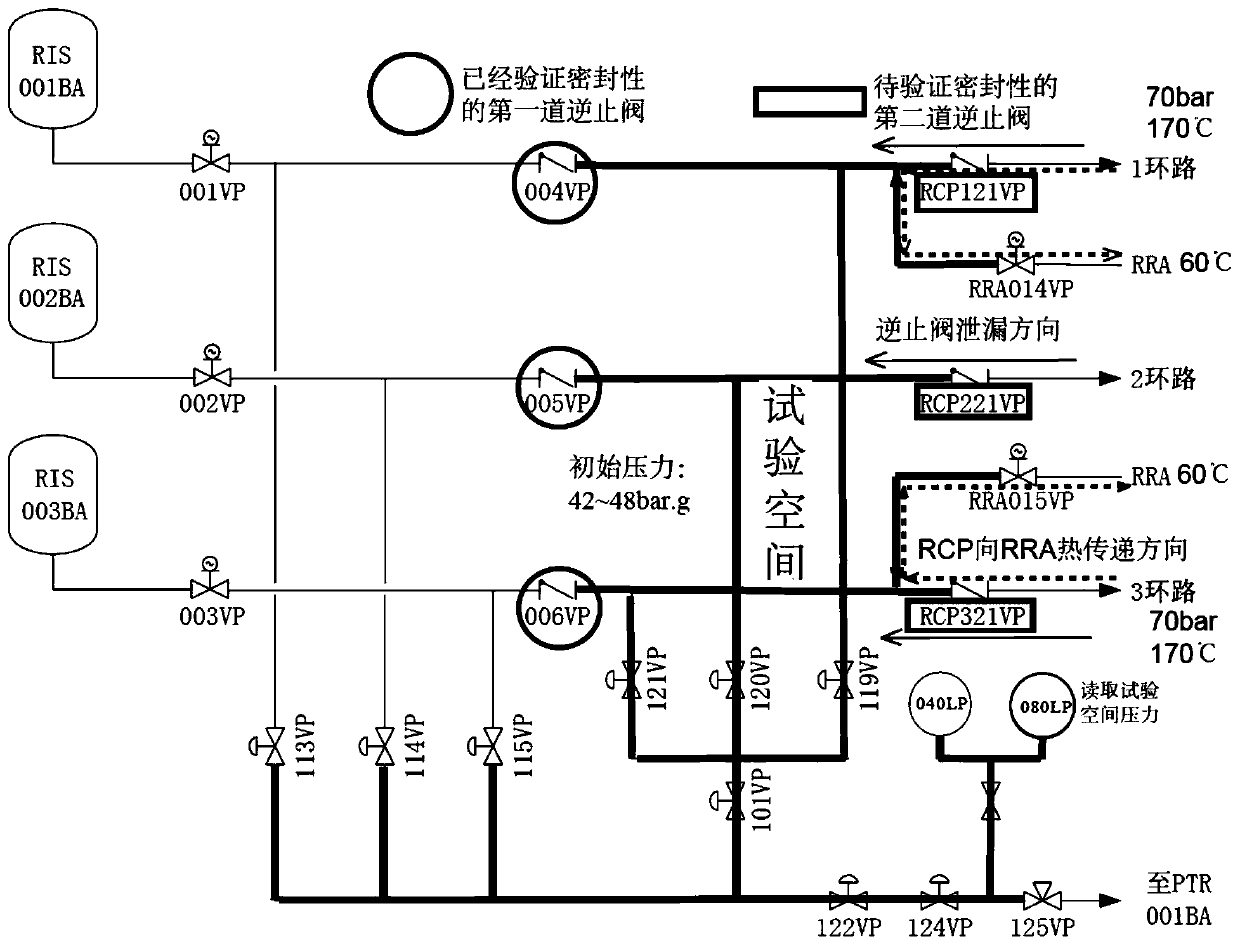

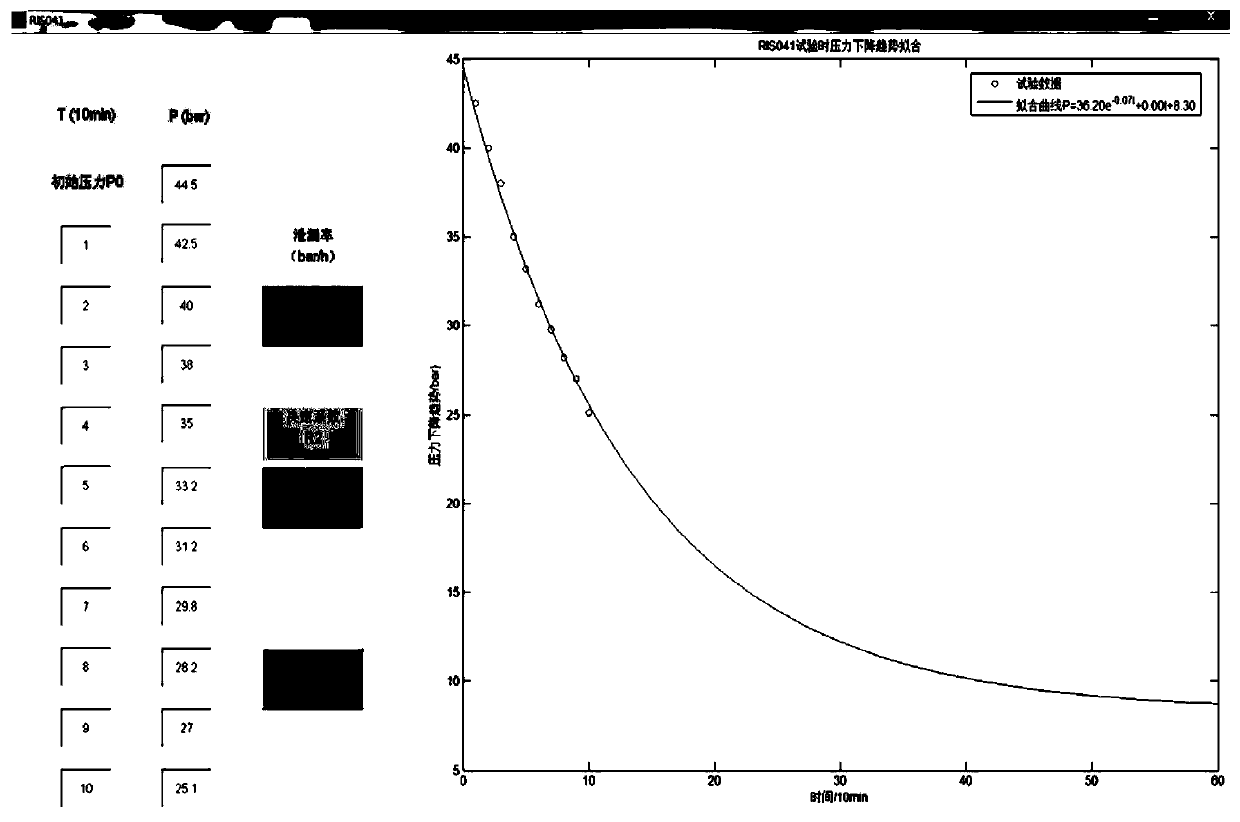

Embodiment Construction

[0046]In the process of research, the inventor found that the negative value in the test was due to the unsatisfied test conditions. The test is required to be carried out under the condition that the temperature of RCP and RRA is stable, but in the uplink stage of the unit, the temperature of the first circuit and the RRA system before the test are both about 170°C, and the RRA system is cooled to below 60°C after isolation, while the RCP121 / 221 / 321VP The temperature in the upstream test area is still about 170°C. When the test is carried out 6 hours later, the RRA system and the primary circuit have not reached temperature equilibrium, which does not meet the test conditions. Test at this time, the first and third loops will transfer heat to the RRA system, causing the temperature in the closed space to drop, and the liquid shrinkage rate in the space is very large, exceeding the leakage rate of the check valve, so that the pressure in the closed space does not rise but rever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com