Toothpaste tube shoulder defect detection method based on Gabor filter

A defect detection, toothpaste tube technology, applied in the direction of instruments, image data processing, calculation, etc., can solve the problems of consumers' health hazards, high similarity, low contrast, etc., and achieve high detection and recognition speed and accuracy, and good direction selection and scale selection, the effect of improving speed and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

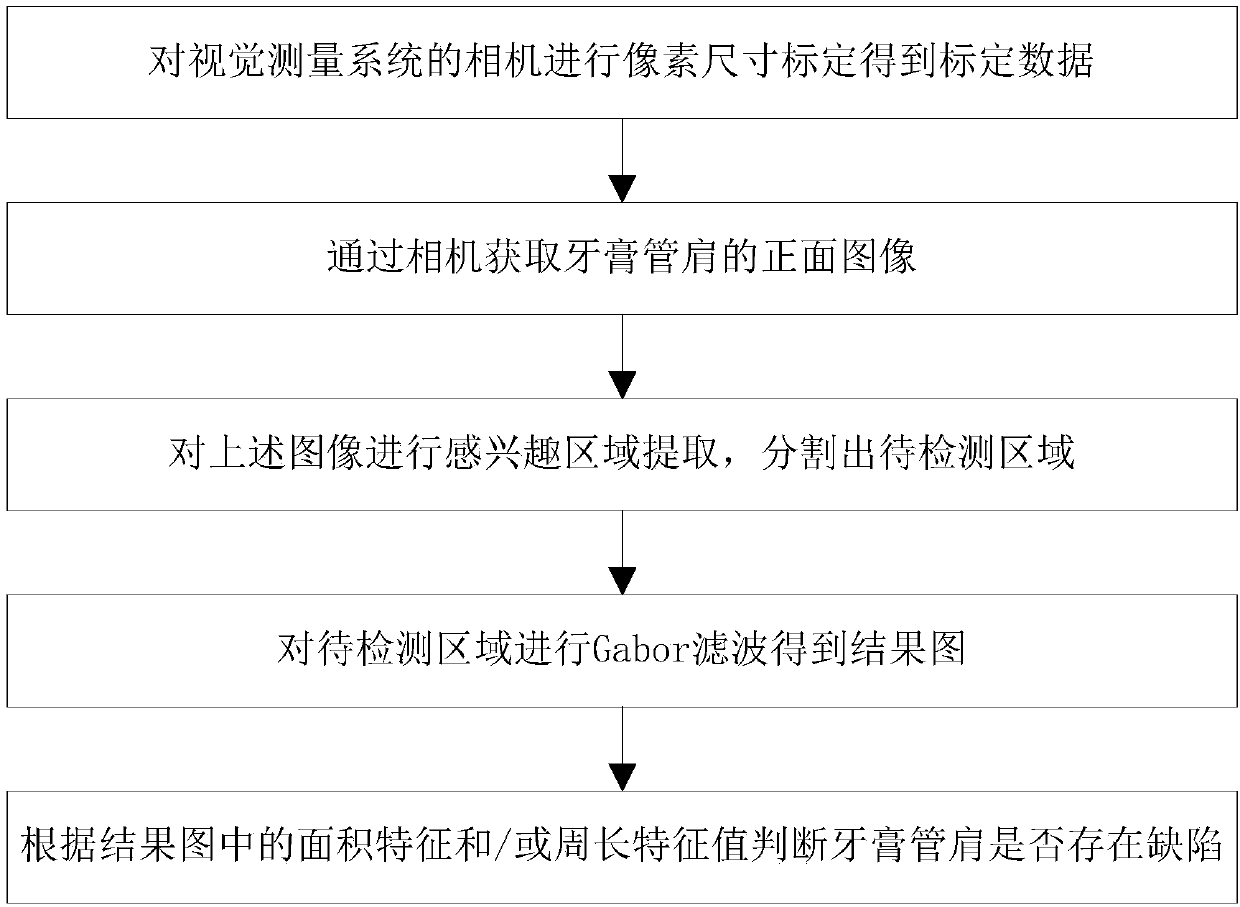

[0048] refer to figure 1 , a kind of toothpaste tube shoulder defect detection method based on Gabor filter, comprises the following steps:

[0049] Perform pixel size calibration on the camera of the visual measurement system to obtain calibration data;

[0050] Obtain the frontal image of the shoulder of the toothpaste tube through the camera;

[0051] Extract the region of interest from the above image, and segment the region to be detected;

[0052] Perform Gabor filtering on the area to be detected to obtain the result map;

[0053] According to the area feature and / or perimeter feature value in the result graph, it is judged whether there is a defect in the toothpaste tube shoulder.

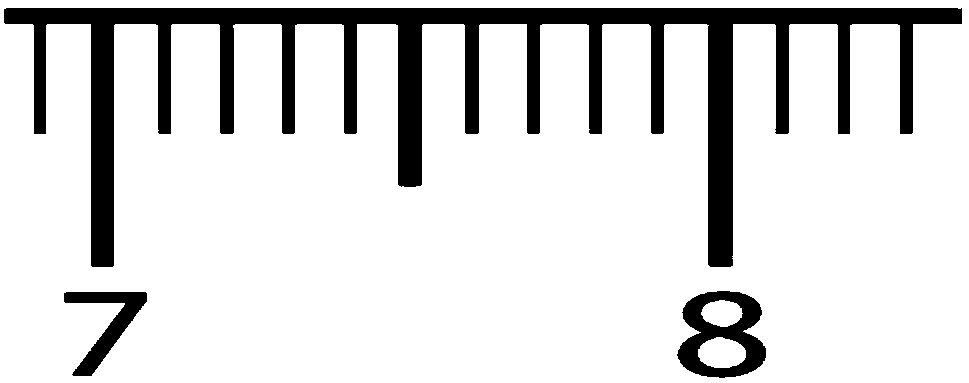

[0054] refer to figure 2 , further as a preferred embodiment, the step of performing pixel size calibration on the camera of the visual measurement system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com