Mount element detection method based on color image segmentation and gradient projection positioning

A color image and gradient projection technology, applied in image analysis, image enhancement, image data processing, etc., can solve the problems of low positioning accuracy and high false detection rate, and achieve the effect of being less susceptible to noise interference and good robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

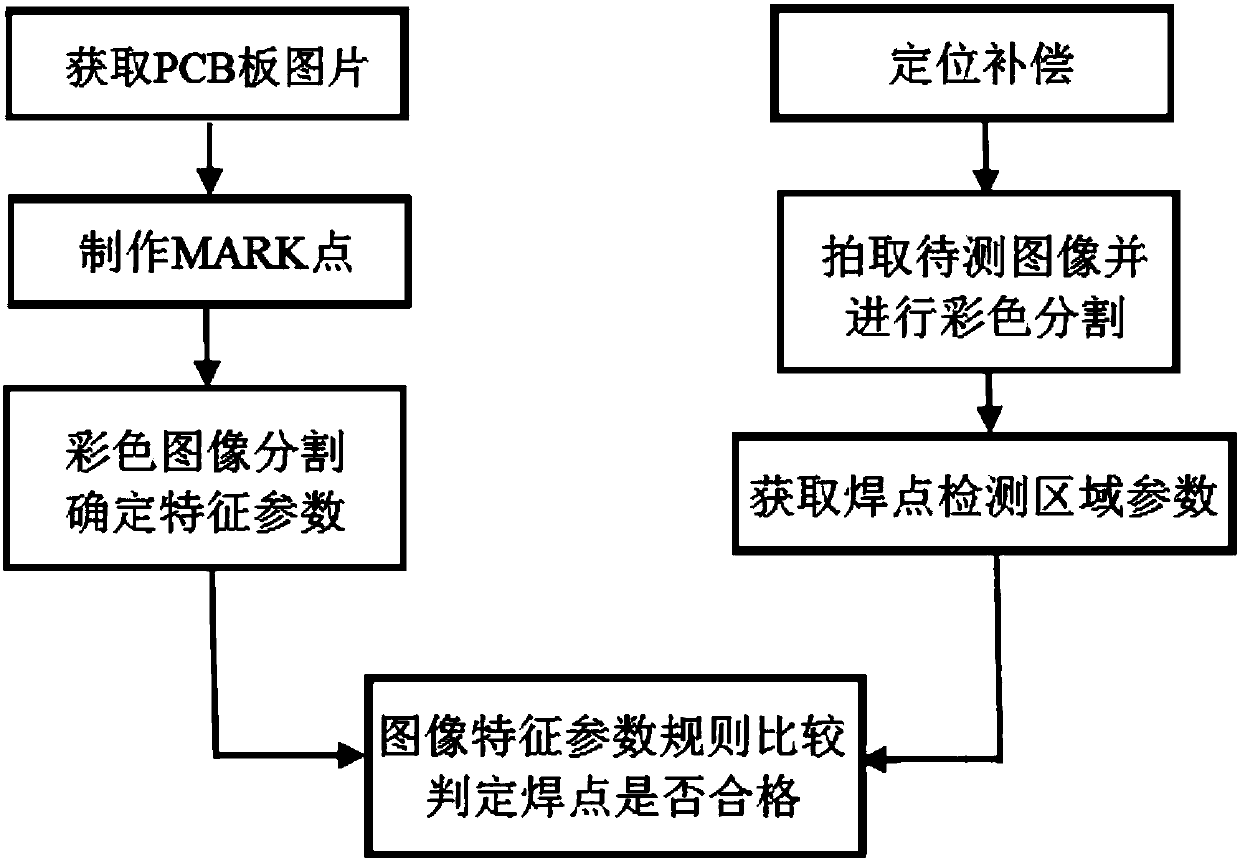

[0045] For the detection of surface mount electronic components as circuit board components, the placement quality of the solder joints directly affects the performance of the circuit board. Because the traditional manual visual inspection has the disadvantages of high false positives and low efficiency, automatic optical It is the current main trend to detect the solder joints of mounted components automatically. This embodiment provides a detection method for mounted components based on color image segmentation and gradient projection positioning, combining figure 1 , which specifically includes the following processes:

[0046] Component defect detection

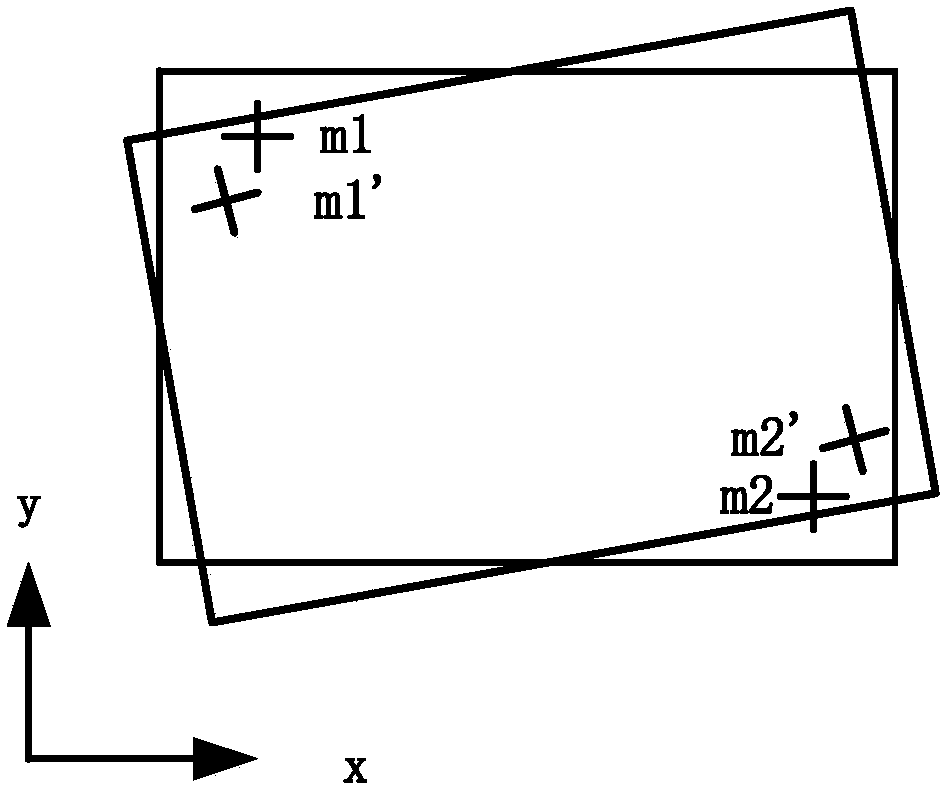

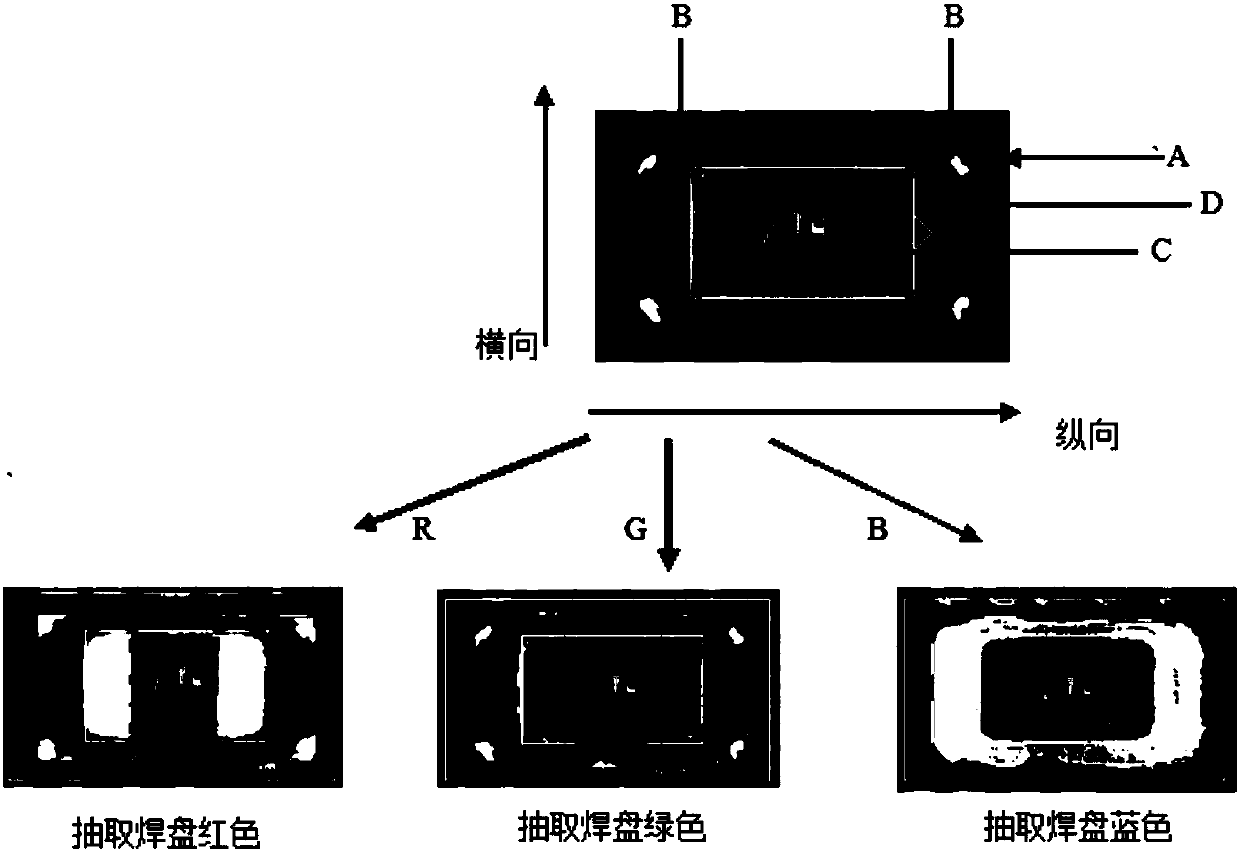

[0047] (1) Training phase: Get the PCB board picture, and use the device of 3CCD camera, ring-shaped red, green and blue LED structure light source and lens to collect the image of the solder joints on the circuit board. Then make the MARK point, and predetermine the characteristic parameters of the solder joint image ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com