Rotor structure for center ladder hole

A technology of rotor structure and stepped holes, which is applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, mechanical energy control, etc., to achieve the effect of reducing the heat generation of the rotor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

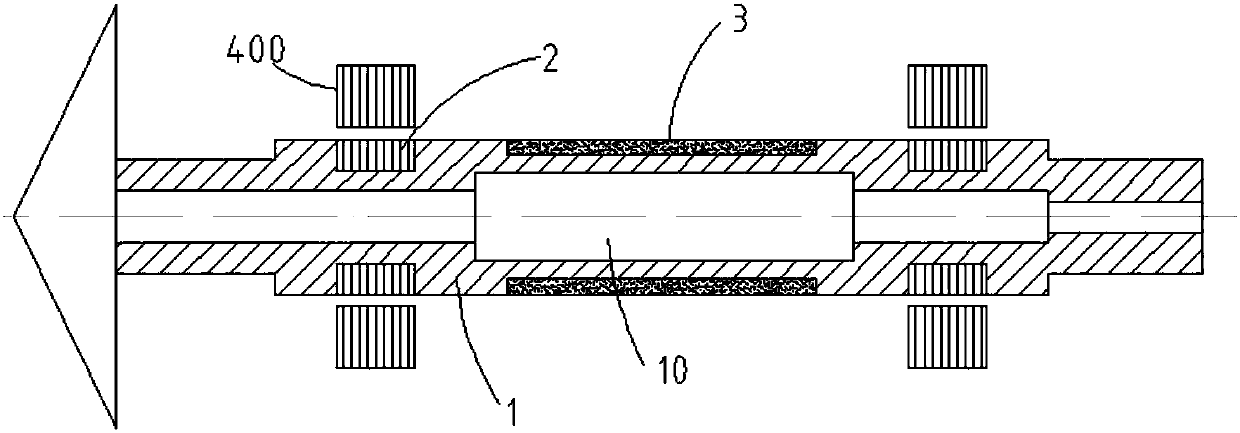

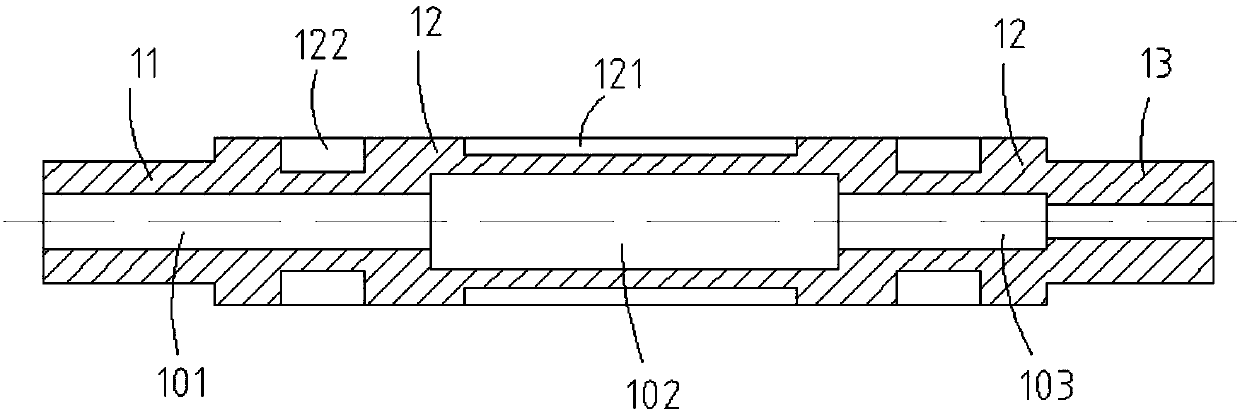

[0020] like figure 1 and figure 2 , the invention discloses a rotor structure with a central stepped hole, including a mandrel 1, a rotor silicon steel sheet 2 and a magnetic steel 3. The mandrel 1 includes an integrally formed and coaxially arranged shaft head 11, an intermediate shaft 12 and a shaft tail. 13. In the axial direction of the mandrel 1, a shaft hole 10 is provided through the shaft head 11, the intermediate shaft portion 12 and the shaft tail 13. The shaft hole 10 includes a first hole 101, a second hole 102 and a second hole. Three hole portions 103, the second hole portion 102 is located at the center of the intermediate shaft portion 12, the first hole portion 101 and the third hole portion 103 are symmetrically located on both sides of the second hole portion 102, and the first hole portion 101 is located from the shaft head The portion 11 extends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com