Performance detection and tin immersion integrated machine of motor stator

A motor stator and integrated machine technology, which is applied in motor generator testing, manufacturing motor generators, electrical components, etc., can solve the problems of affecting economic benefits, low processing efficiency, and high labor costs, so as to improve economic efficiency and reduce labor costs. , the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

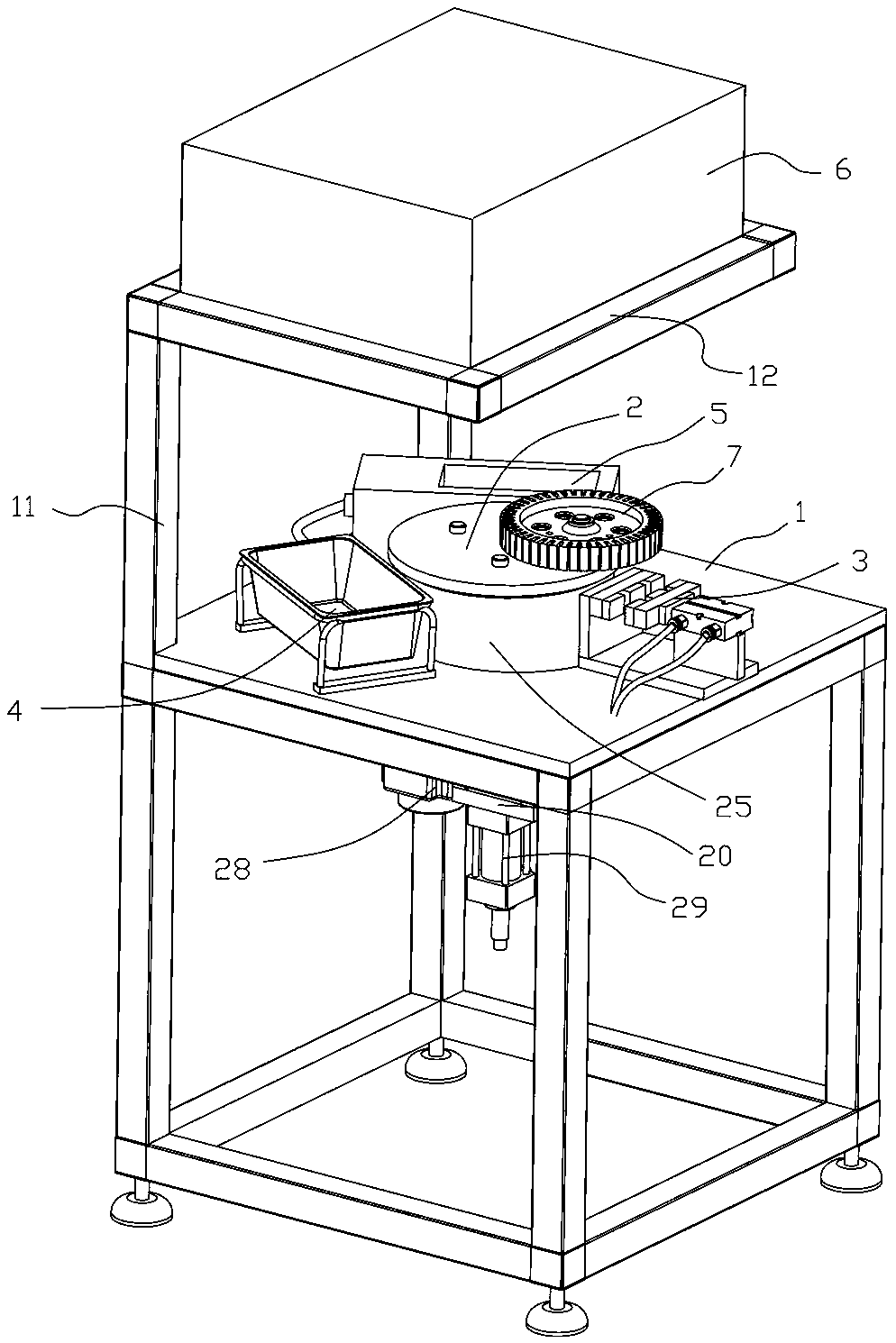

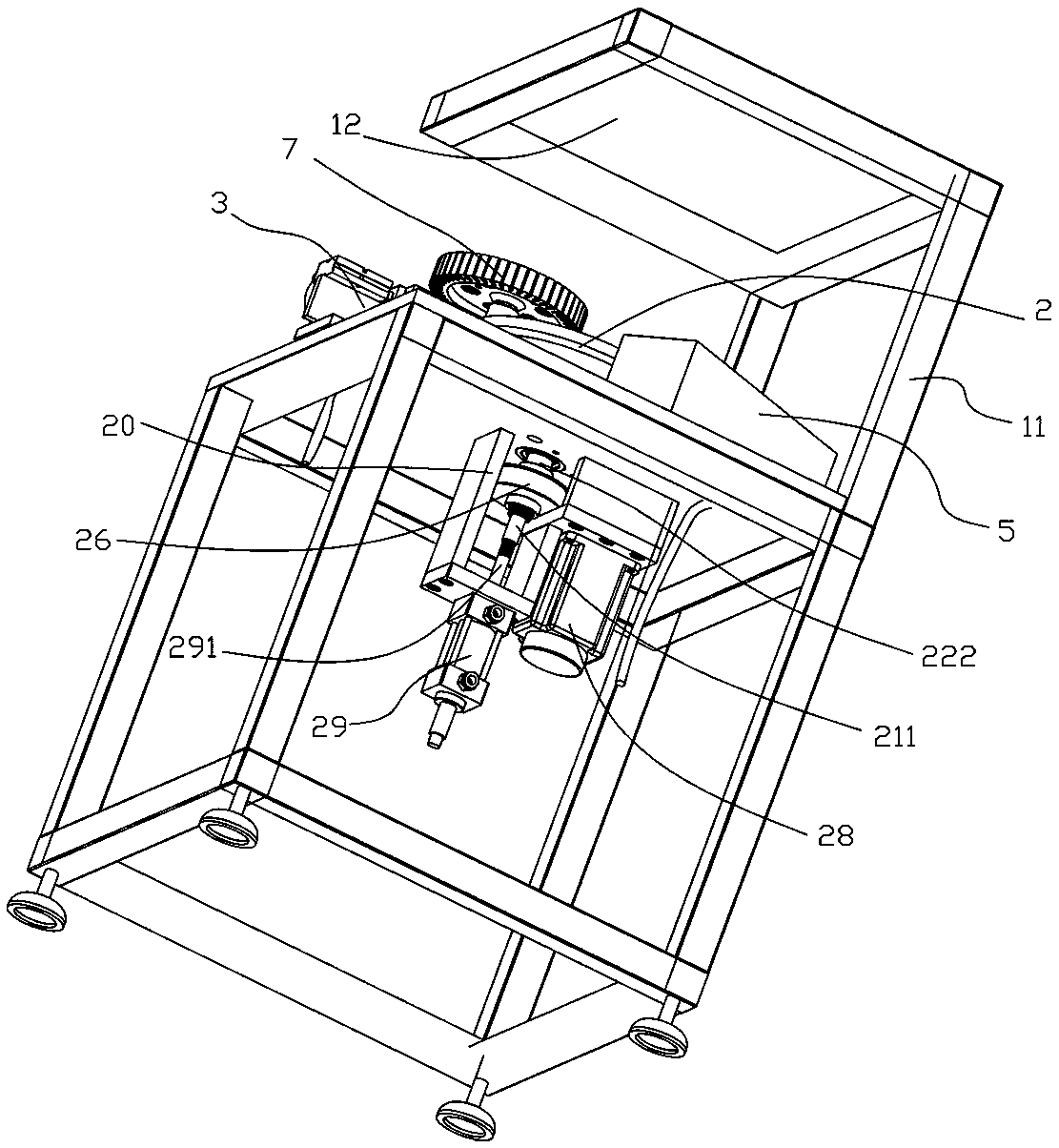

[0018] like Figure 1-4 As shown, a motor stator performance detection and tin immersion integrated machine includes a working platform 1 on which a turntable mechanism 2 and detection chucks 3 arranged at equal intervals in the circumferential direction around the turntable mechanism are arranged. Flux tank 4 and tin furnace 5.

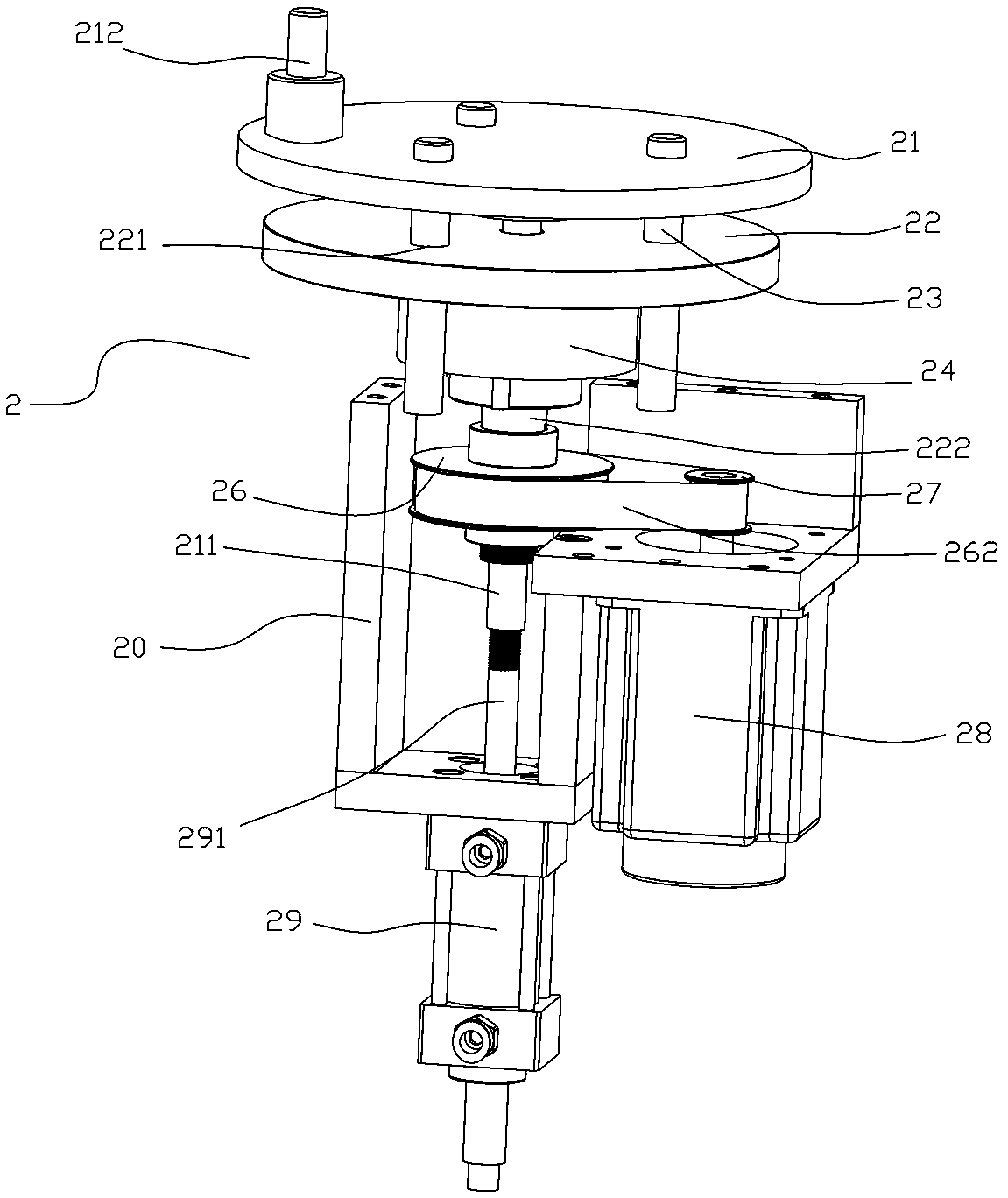

[0019] The turntable mechanism 2 includes a vertically spaced and coaxial lifting disk 21 and a rotating disk 22 .

[0020] A plurality of guide pillars 23 are arranged between the lifting disk 21 and the rotating disk 22 . The structure of the guide column 23 above ensures the synchronous rotation of the lifting disc 21 and the rotating disc 22 on the one hand, and ensures the coaxial precision of the lifting disc 21 relative to the rotating disc 22 at the same time.

[0021] The rotating disk 22 is movably mounted on the working platform 1 through a base 24 , and a shield 25 is provided outside the rotating disk 22 . A hollow rotating shaft 222 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com