Intelligent control hydraulic-drive aspirated-air type wheat seeding device

An air-suction, wheat technology, used in shovels, plows, agricultural machinery and implements, etc., can solve problems such as seed shedding, seed breakage, and unstable sowing performance, and achieve the effect of reducing pressure loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

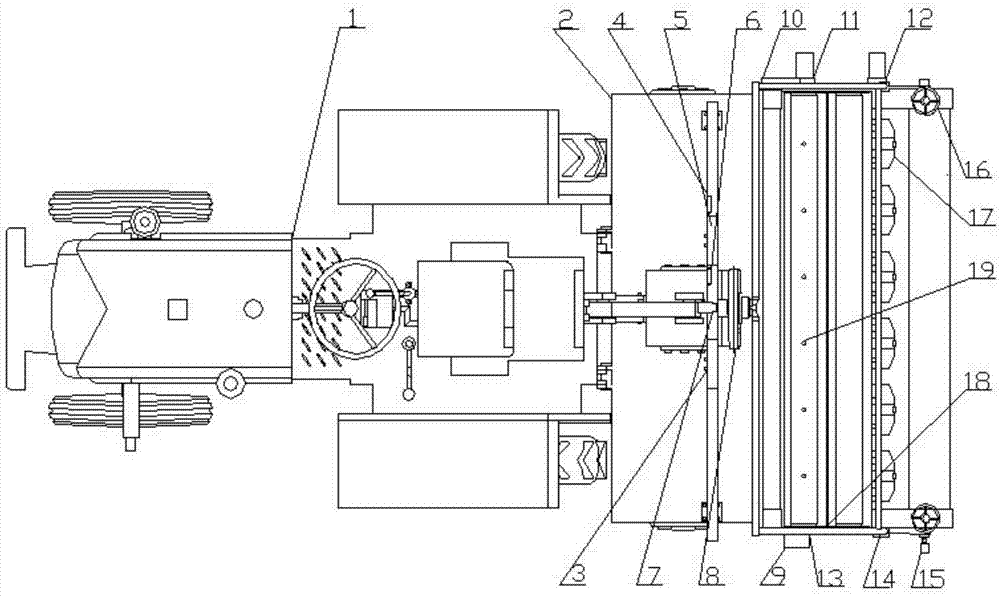

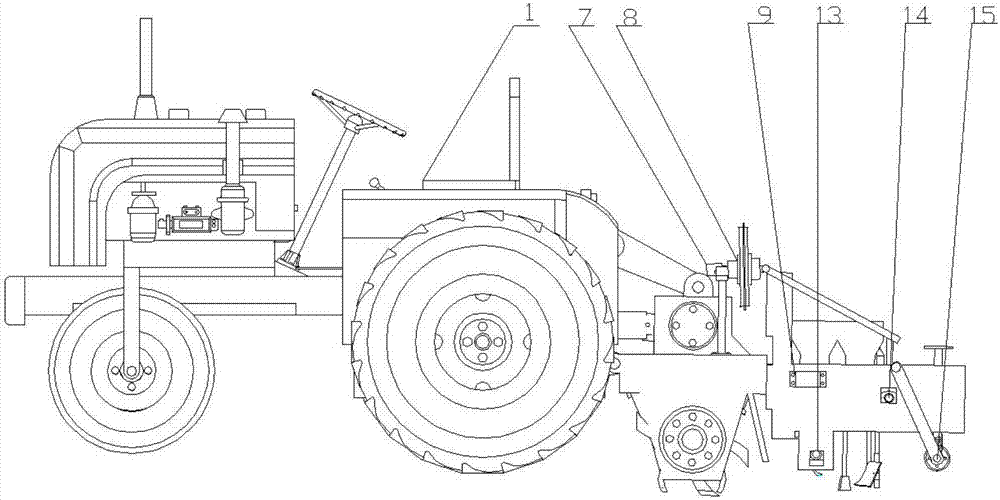

[0035] Example 1, see Figure 1-Figure 6 As shown, a kind of intelligent control hydraulically driven air-suction wheat sowing device includes a rotary cultivator 2 connected to the tractor 1, a fertilizer discharger 18 and a seed meter 17 connected to the rotary cultivator 2, and also includes a rotary cultivator located at The negative pressure fan 8 on the machine 2, the negative pressure fan 8 has double suction cups opposite to the air suction direction, and the double suction cups are connected with the air pipe of the seed meter 17.

[0036] As a preference, the negative pressure fan 8 is driven by a high-speed hydraulic motor 7, the fertilizer discharger 18 and the seed metering device 17 are respectively driven by a low-speed hydraulic motor I11 and a low-speed hydraulic motor II12, and each hydraulic motor is connected to the main controller 9 ; The high-speed hydraulic motor 7, low-speed hydraulic motor I11 and low-speed hydraulic motor II12 are all driven by the hy...

Embodiment 2

[0043] Example 2, see Figure 8 The difference between this embodiment and Embodiment 1 is that, on the basis of Embodiment 1, a pressure maintaining circuit is provided on the branch road of the hydraulic pump station driving the high-speed hydraulic motor 7 and the negative pressure fan 8. The pressure maintaining circuit includes a pressure sensor 4 installed at the air inlet of the negative pressure fan and an electro-hydraulic proportional valve 3 installed between the hydraulic pump station and the high-speed hydraulic motor 7, the pressure sensor 4, the electro-hydraulic proportional valve 3 It is electrically connected with the main controller 9.

[0044] In the branch where the high-speed hydraulic motor is connected to the fan, a pressure-holding circuit is designed. The purpose of setting up the pressure-holding circuit is to make the fan have a constant pressure, so as to prevent the tractor from turning and turning around due to unstable wind pressure and reduced ...

Embodiment 3

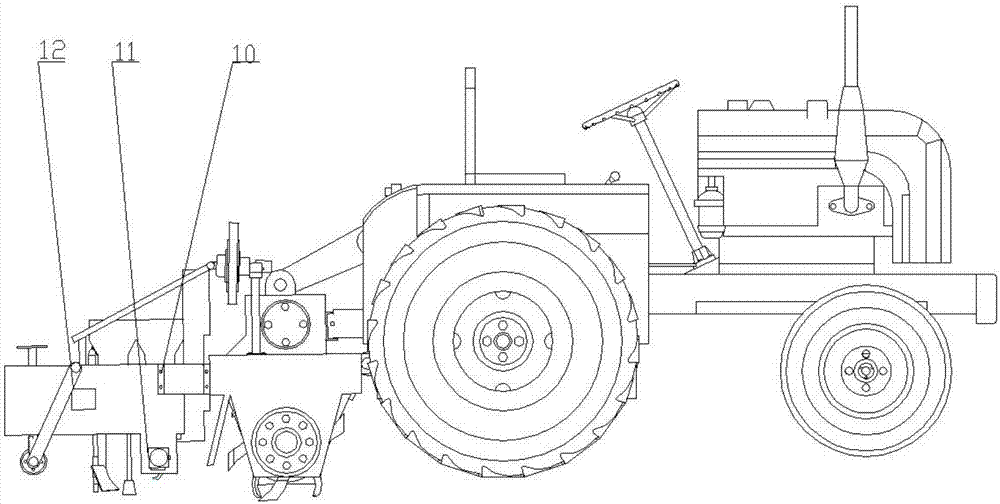

[0045] Embodiment 3, the difference between this embodiment and Embodiment 1 or Embodiment 2 is that, on the basis of Embodiment 1 or Embodiment 2, a photoelectric encoder 14 is installed at one end of the seeding shaft of the seed metering device 17 A photoelectric encoder 13 is installed at one end of the fertilizer discharge shaft of the fertilizer discharger 18, and the photoelectric encoder 13 and the photoelectric encoder 14 are respectively electrically connected to the main controller 9.

[0046] Ground wheel 16 is installed on the end both sides of rotary tiller 2, and photoelectric encoder 15 is installed on the rotating shaft of ground wheel 16, and described photoelectric encoder 15 is electrically connected with main controller 9. The ground wheels 16 are used for the forward operation of the rotary cultivator 2, consistent with the running speed of the tractor. The photoelectric encoder 15 measures the speed of the tractor 1 .

[0047] Install a photoelectric en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com