Small seed wind separator

A cleaning machine and seed technology, applied in the direction of solid separation, sieve, grid, etc., can solve the problems that can not fully meet the requirements of small seed production, can not adapt to the cleaning of the amount of seeds per plant, mixed seeds, etc. Simple, good cleaning effect, stable work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

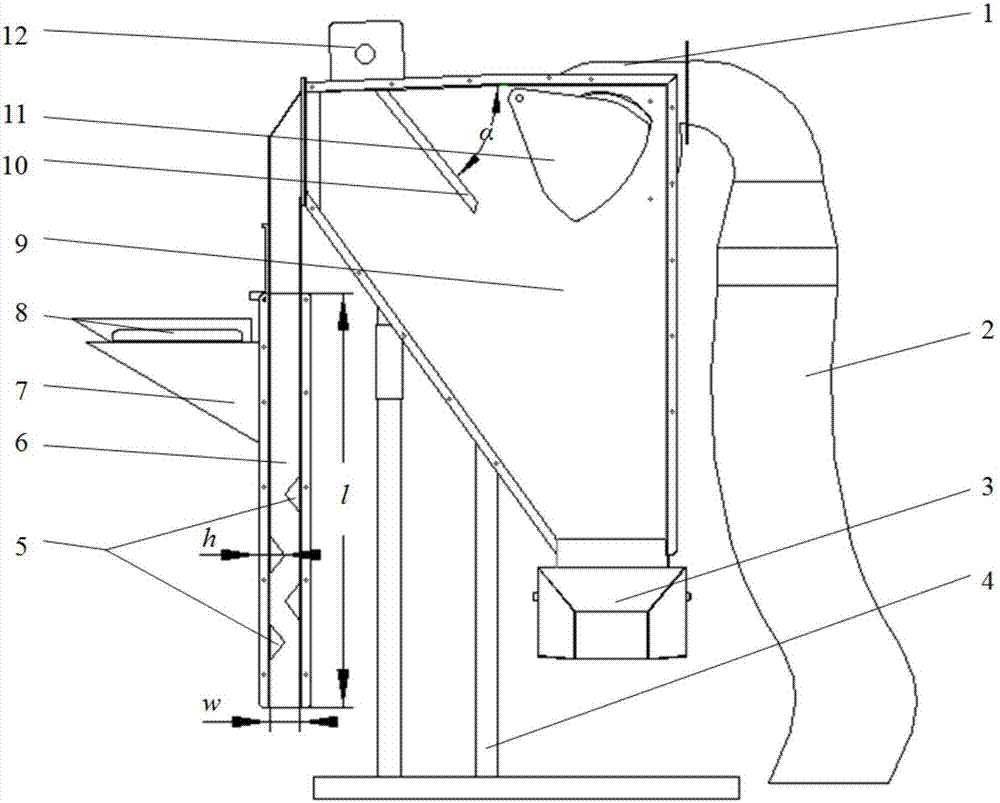

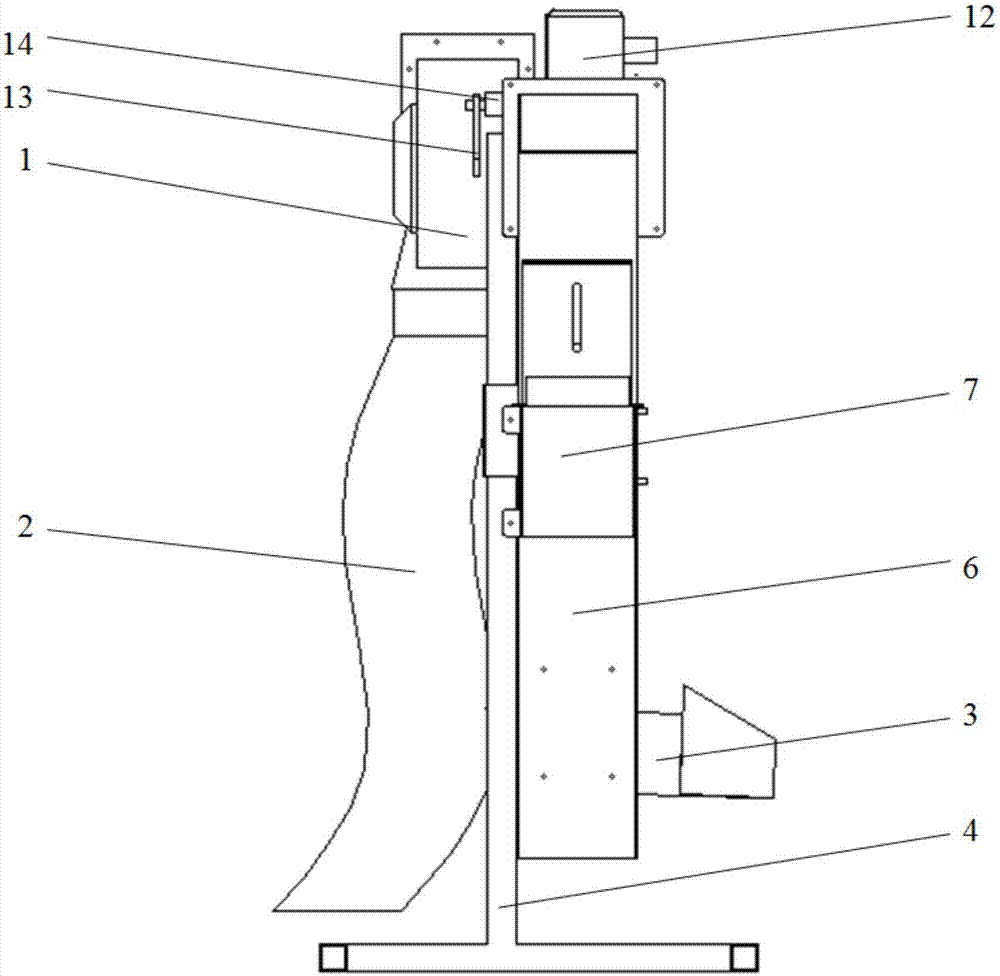

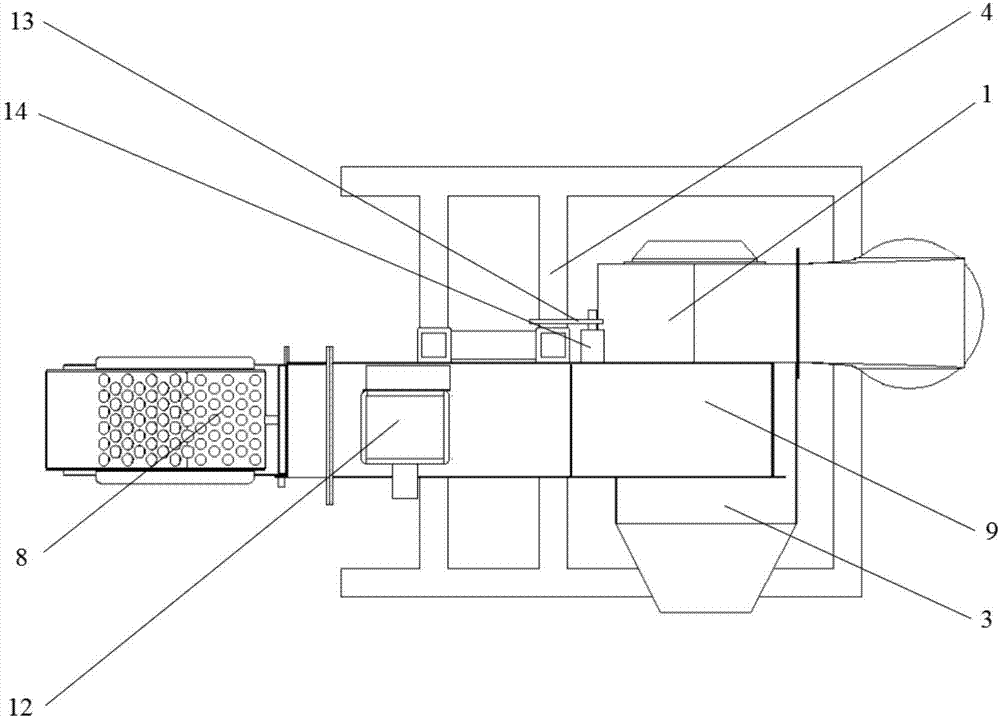

[0011] The invention will be further described below in conjunction with the accompanying drawings and embodiments. A small wind-powered seed cleaning machine, which includes a fan 1, a dust bag 2, an impurity collection box 3, a frame 4, a seed guide bar 5, a cleaning room 6, a feeding hopper 7, a feeding screen 8, and a settling chamber 9 , airflow guide plate 10, regulating damper 11, power switch 12; Described settling chamber 9 can be adjusted up and down and fitted on the frame 4, and on the settling chamber 9, cleaning chamber 6, blower fan 1, and settling chamber are fixed successively. The inside of the settling chamber 9 is fixed with an airflow guide plate 10, and the inside of the settling chamber 9 is located at the air inlet of the fan 1, and the damper 11 is rotatably installed. A feed hopper 7 is fixed above the feed hopper 7, and a feed screen 8 is installed above the feed hopper 7. The outlet of the fan 1 is equipped with a dust-removing bag 2. The cleaning c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com