Sliding block type core assembly tool

A slider-type, core-assembling technology, which is applied in the direction of cores, manufacturing tools, metal processing equipment, etc., can solve the problems of large human influence, large matching error, and easy shaking, etc., to increase accuracy and efficiency, and tooling production The effect of simplicity and high assembly precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

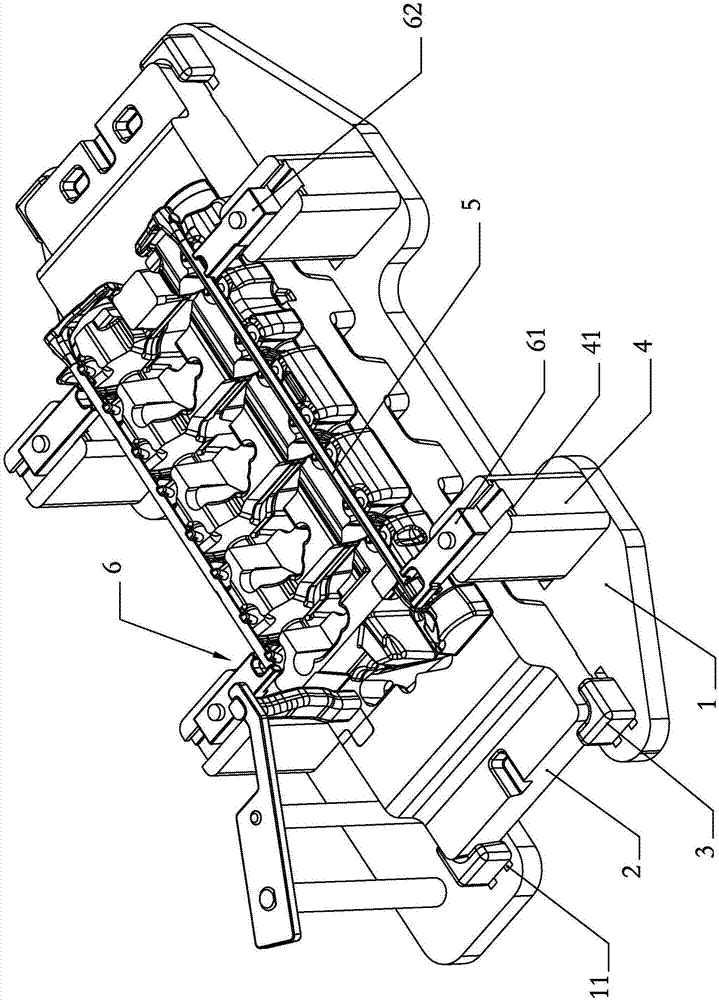

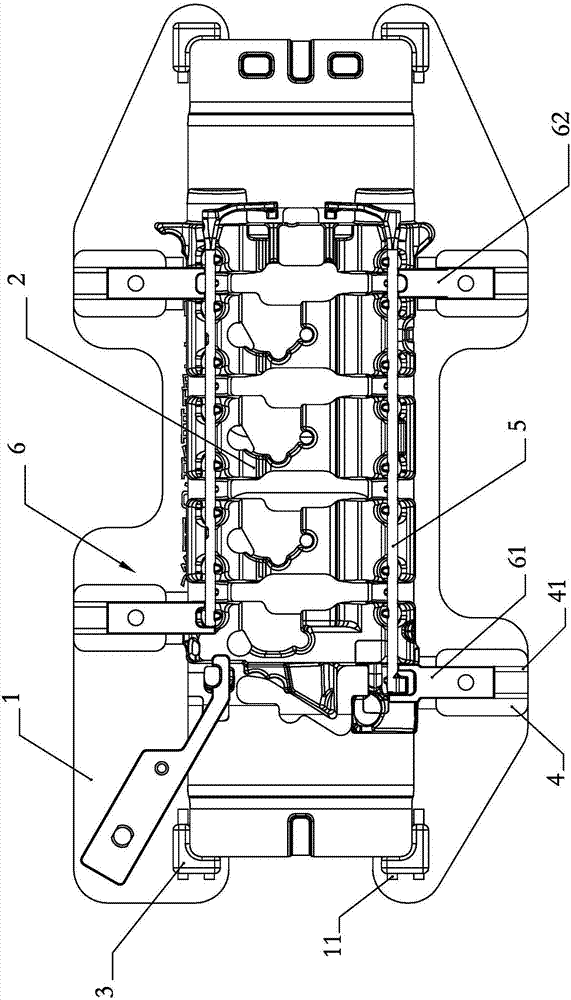

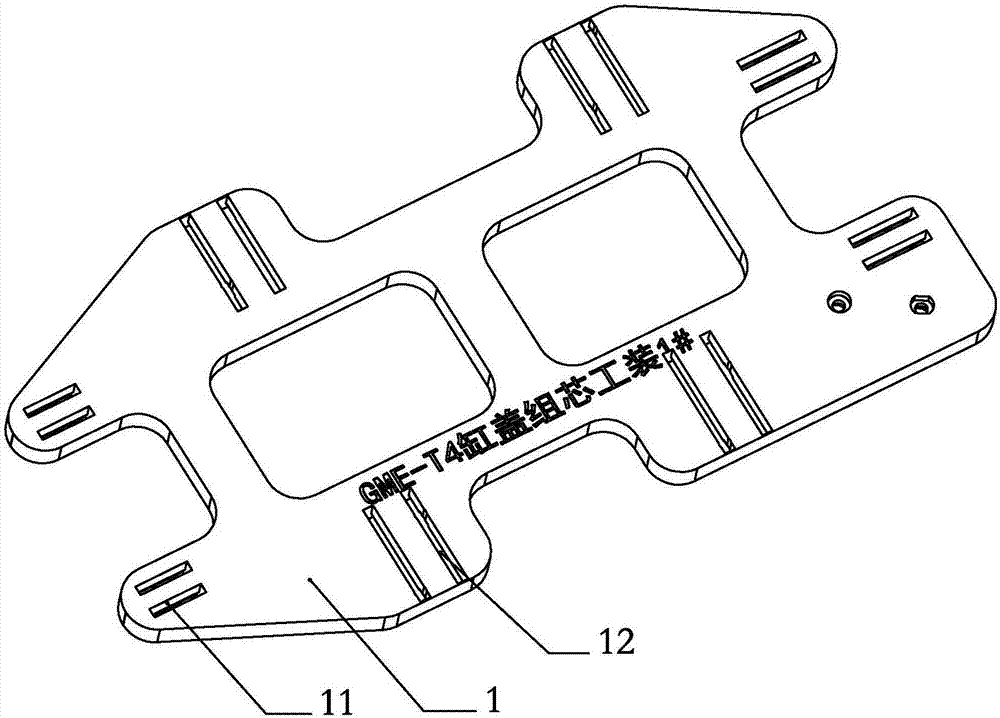

[0019] like Figure 1-7 As shown, the present invention is a slider-type core assembly tool, which includes a mounting base 1, and a plurality of positioning blocks 3 that limit the horizontal and vertical movement of the riser sand core 2 are arranged on the end surface of the mounting base 1. The block 3 is fixedly connected with the mounting seat 1; on both sides of the mounting seat 1, a plurality of positioning columns 4 are arranged, and on the positioning columns 4, a positioning slide block 6 that can limit the horizontal and vertical movement of the sand core 5 of the oil channel is arranged, so that The positioning slider 6 described above can be displaced longitudinally along the positioning column 4 and fixedly connected with the positioning column 4; The two corners are fixed, so as to effectively avoid the displacement of the riser sand core 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com