Full-automatic multifunctional refractory and fireproof glass production line for temperature-sensitive and photosensitive color-varying glass

A technology of photosensitive discoloration and fireproof glass, applied in the direction of layered products, lamination devices, lamination auxiliary operations, etc., can solve the problems of inability to guarantee product accuracy and quality, inability to mass produce, low production efficiency, etc., to reduce repeated investment , easy operation, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

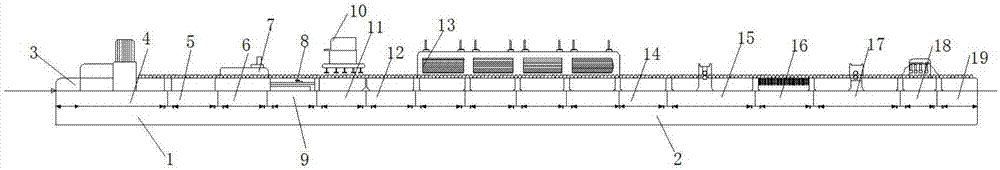

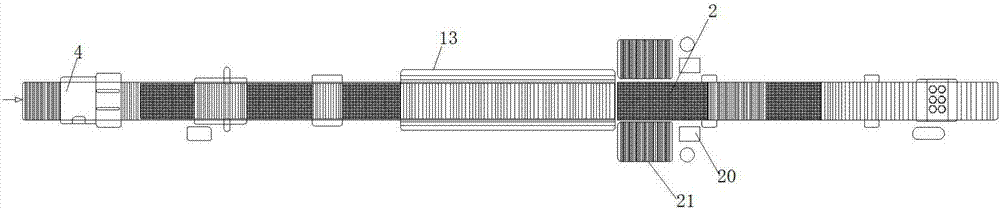

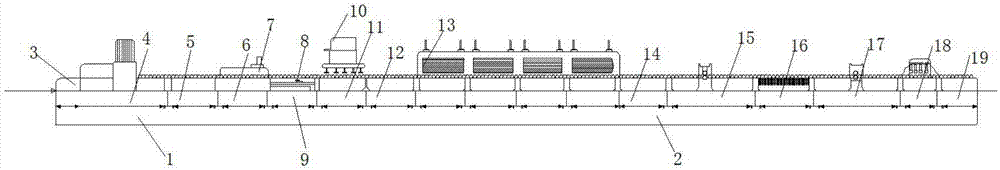

[0020] Such as Figure 1-2 As shown, the present invention provides a fully automatic fire-resistant and fire-resistant glass production line for multifunctional temperature-sensitive and photochromic glass, including a first high-speed conveying platform 1, a second high-speed conveying platform 2 is arranged at one end of the first high-speed conveying platform 1, and a second high-speed conveying platform 2 is arranged on the first high-speed conveying platform 1 The other end of a high-speed conveyor table 1 is provided with a film inlet 3, and one end of the film inlet 3 is equipped with a glass drying and cleaning machine 4, and one end of the glass drying and cleaning machine 4 is provided with a first automatic positioning machine 6, and the first automatic positioning machine 6 One end is provided with a second automatic positioning machine 11, a second transition section 9 is provided between the first automatic positioning machine 6 and the second automatic positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com