Turning plate type anti-backfire biomass particle feeding device

A biomass particle and feeding device technology, applied in supply configuration, fuel supply, combustion method, etc., can solve problems such as potential safety hazards of biomass burners, and achieve the effects of simple structure, prevention of combustion, and convenient manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

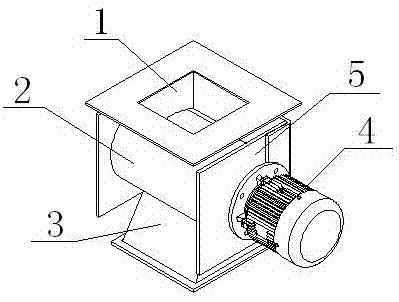

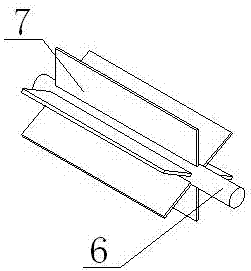

[0014] A flap type anti-tempering biomass pellet feeding device, comprising a feed hopper 1, a feed bin 2, a drop bin 3 and a motor 4, the feed bin 2 is a circular tube placed horizontally, the feed bin The upper and lower sides of the feed bin 2 are provided with openings, the lower end of the feed hopper 1 is connected with the opening at the upper end of the feed bin 2, the upper end of the falling feed bin 3 is connected with the opening at the lower end of the feed bin 2, and the feed bin 2 is connected with the upper end of the feed bin 2. The left and right ends of the bin 2 are respectively provided with end plates 5, and the motor 4 is installed on one of the end plates 5. A rotating shaft 6 consistent with its axis is arranged in the feeding bin 2, and one end of the rotating shaft 6 is connected to the motor 4. The other end of the rotating shaft 6 is mounted on the end plate 5 through a bearing, and the outer surface of the rotating shaft 6 is evenly distributed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com