Ultrasonic fatigue average stress loading device

A technology of average stress and loading device, which is used in measuring devices, analyzing solids using sonic/ultrasonic/infrasonic waves, and using sonic/ultrasonic/infrasonic waves for material analysis to achieve low power consumption, shorten fatigue test time, and ensure resonance requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

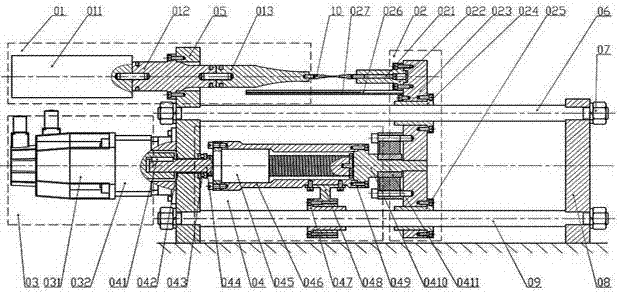

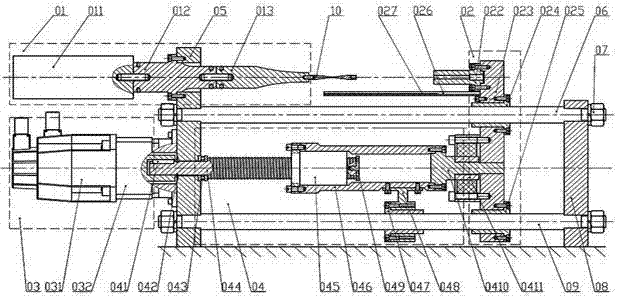

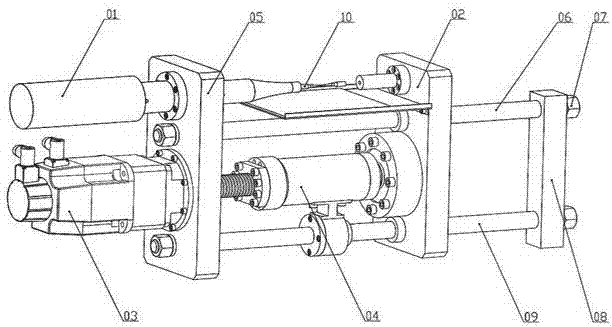

[0014] Such as figure 1 , figure 2 and image 3As shown, an ultrasonic fatigue average stress loading device of the present invention is composed of an ultrasonic generating assembly 01, a stress loading assembly 02, a power assembly 03, a linear transmission assembly 04, a bracket vertical plate 05, a sliding guide rod a06, a locking The nut 07, the positioning end plate 08, the sliding guide rod b09 and the test piece 10 are composed. The ultrasonic generating assembly 01 includes a piezoelectric transducer 011, a positioning seat 012 and a displacement amplifier 013. The stress loading assembly 02 includes a tension screw 021, a loading support Seat 022, loading slide plate 023, linear sliding sleeve a024, linear sliding sleeve b025, tray 026 and rubber pad 027, power assembly 03 includes servo motor 031 and reducer 032, linear transmission assembly 04 includes transmission key 041, spring collar 042, thrust bearing 043, ball screw 044, screw nut 045, sleeve 046, linear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com