Wire stripping treatment device and method

A technology for processing devices and wires, applied in circuit/collector parts, electrical components, circuits, etc., can solve the problems of earphone wire core wires and pads not fully fitted, difficult to control the length of tin tinting, affecting physical health, etc. , to achieve the effect of improving welding quality and welding appearance, improving welding quality and welding appearance and welding stability, increasing versatility and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

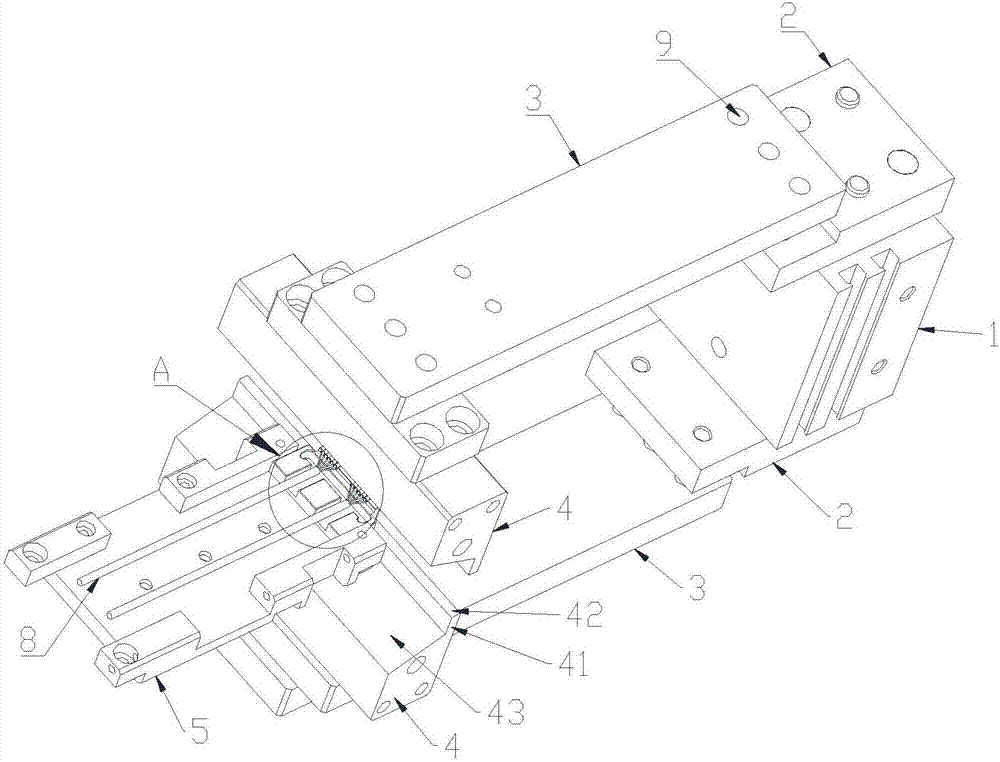

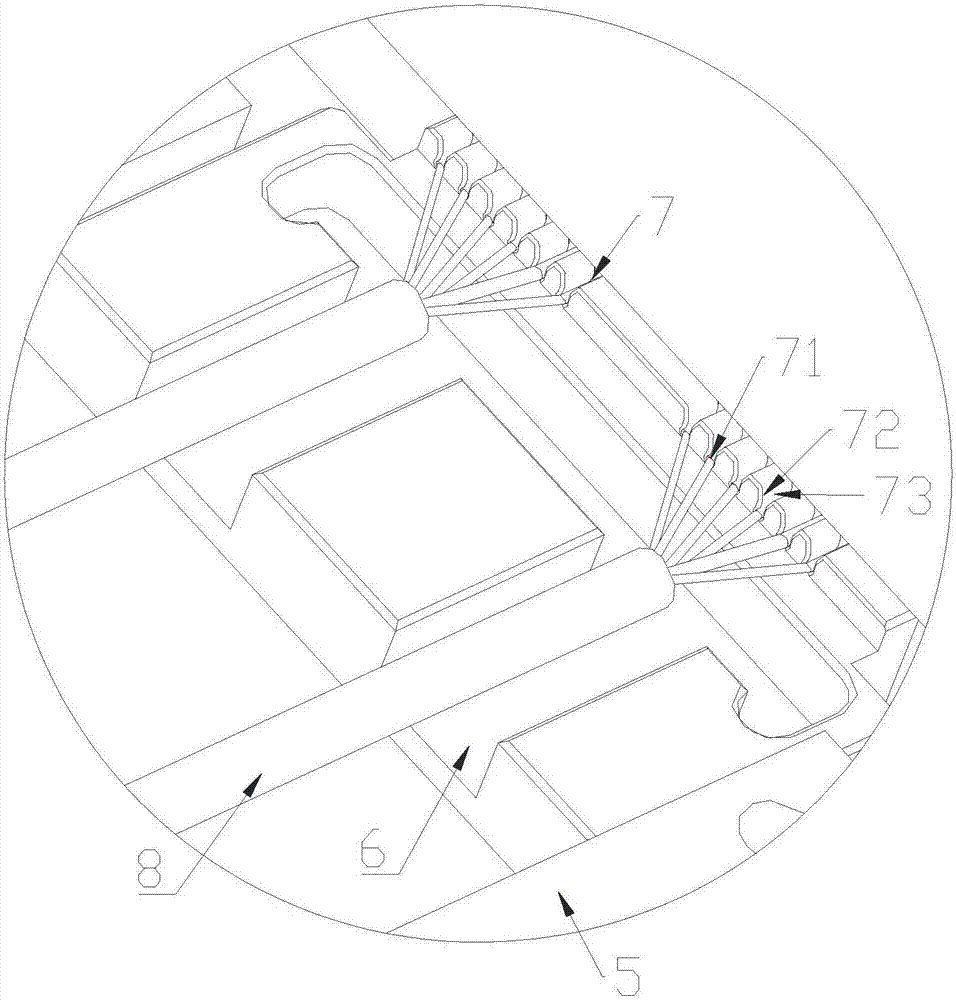

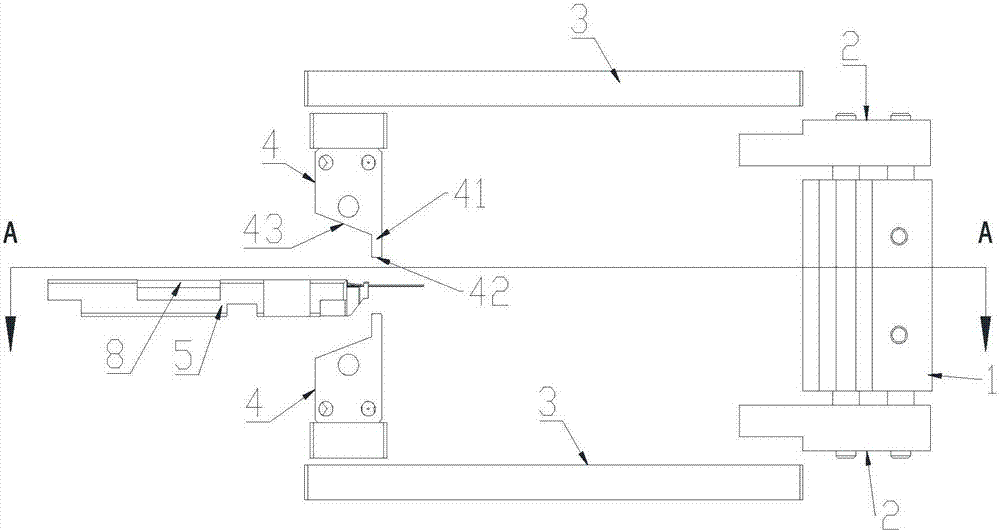

[0034] Figure 1-4 A wire peeling treatment device according to an embodiment of the present invention is schematically shown. As shown in the figure, the device includes a driving mechanism 1 , a heating mechanism 4 and a jig 5 . There are two heating mechanisms 4, one end of the heating mechanism 4 is connected to the driving mechanism 1 through a connecting arm;

[0035] The driving mechanism 1 is a finger cylinder, and the connecting arm includes a first connecting arm 3 and a second connecting arm 2 . Both the first connecting arm 3 and the second connecting arm 2 are provided with threaded holes 9, one end of the second connecting arm 2 is connected with one end of the first connecting arm 3 by a bolt, and the jaw of the finger cylinder is connected with the second connecting arm by a bolt. The other end of arm 2 is fixed. The other end of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com