Soldering flux in use for iron weldment

A technology of flux and weldment, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of tin connection, exposed base material, virtual soldering, etc., and achieve easy cleaning and bright lead-tin coating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

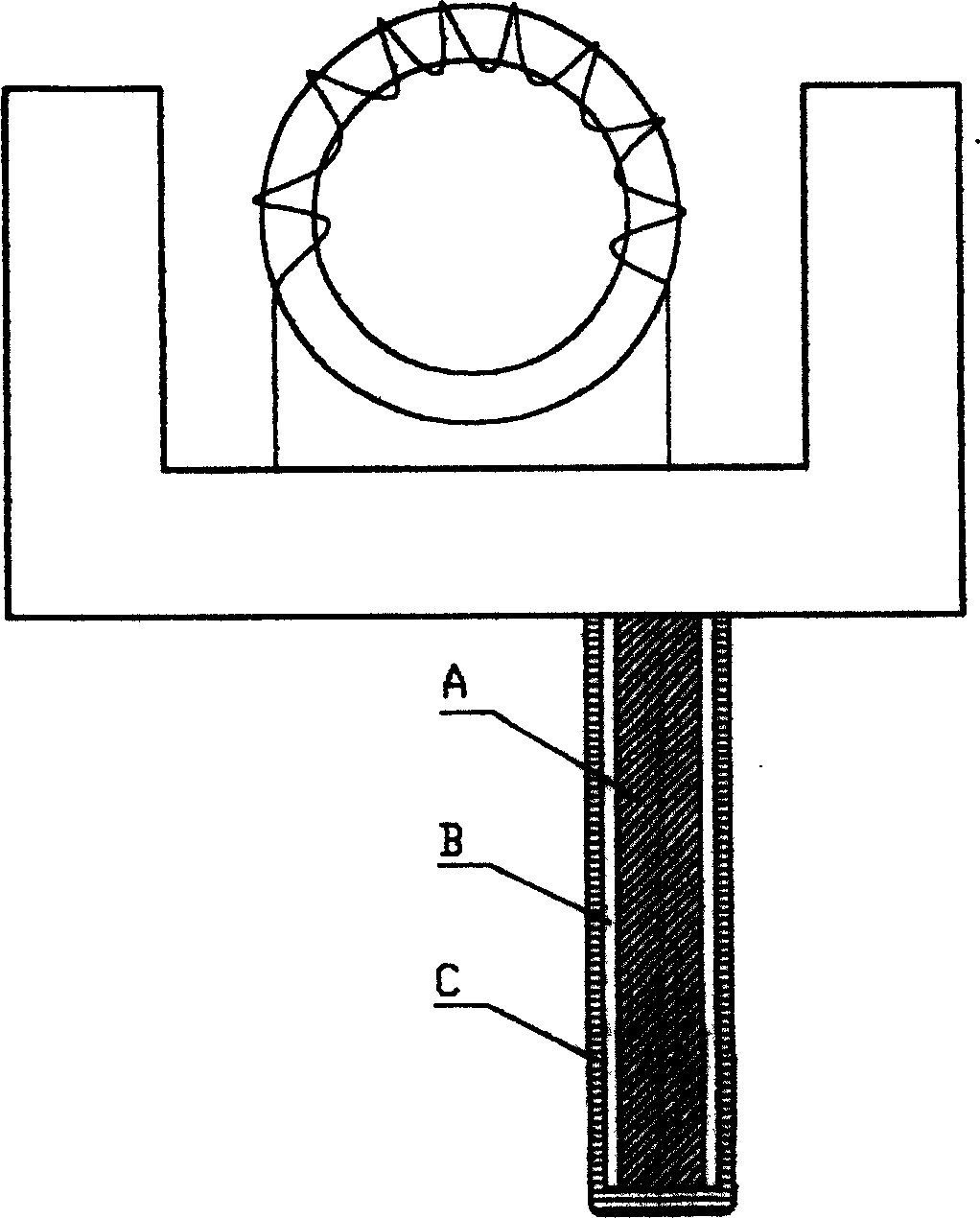

Image

Examples

Embodiment 1

[0023] Embodiment 1: a kind of flux that is used for ferrous weldment, its component and content are:

[0024] o-Chlorophenylacetic acid 30 g / L;

[0025] Glycolic acid 2% (volume);

[0026] Propylene glycol modified polymer 8% (volume);

[0027] Molecular weight is 35% (volume) of fatty alcohol polyoxyethylene ether of 60,000;

[0028] The remainder is propylene glycol.

Embodiment 2

[0029] Embodiment 2: a kind of flux that is used for ferrous weldment, its component and content are:

[0030] p-Hydroxyphenylacetic acid 20 g / L;

[0031] Acetic acid 1% (volume);

[0032] Propylene glycol modified polymer 5% (volume);

[0033] Molecular weight is 20% (volume) of fatty alcohol polyoxyethylene ether of 40,000;

[0034] The rest is isopropanol.

Embodiment 3

[0035] Embodiment 3: a kind of flux that is used for ferrous weldment, its component and content are:

[0036] Isophthalic acid 50 g / l;

[0037] Acetic acid 5% (volume);

[0038] Propylene glycol modified polymer 10% (volume);

[0039] Molecular weight is 50% (volume) of fatty alcohol polyoxyethylene ether of 40,000;

[0040] The remainder is propylene glycol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com