A connection structure and method between a db small board and a pcb board

A PCB board and connection method technology, which is applied in the field of connection structure between DB small board and PCB board, can solve the problems of high defect rate, leakage and outflow of defective products, and achieve good tinning effect, avoid defective products, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

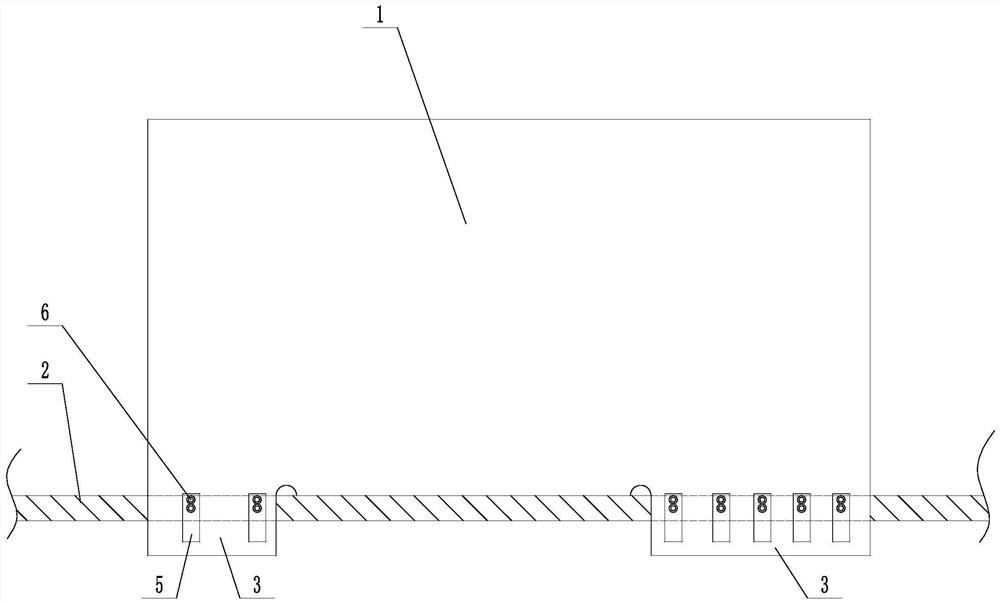

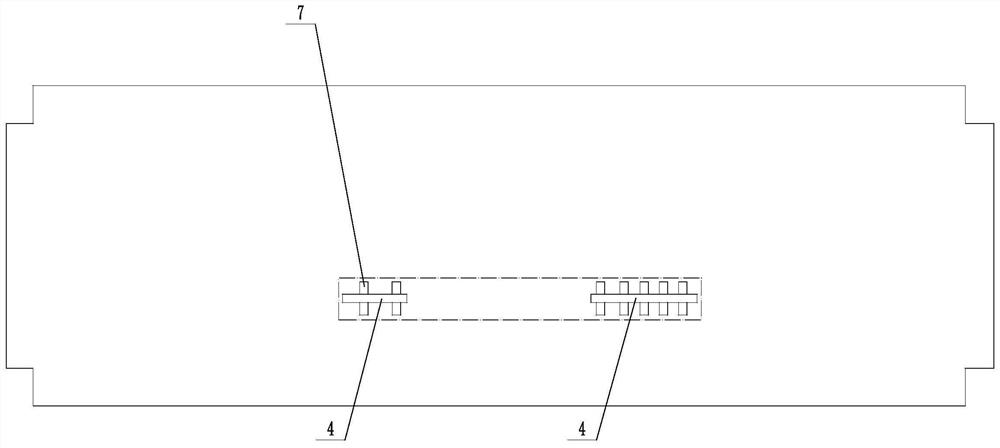

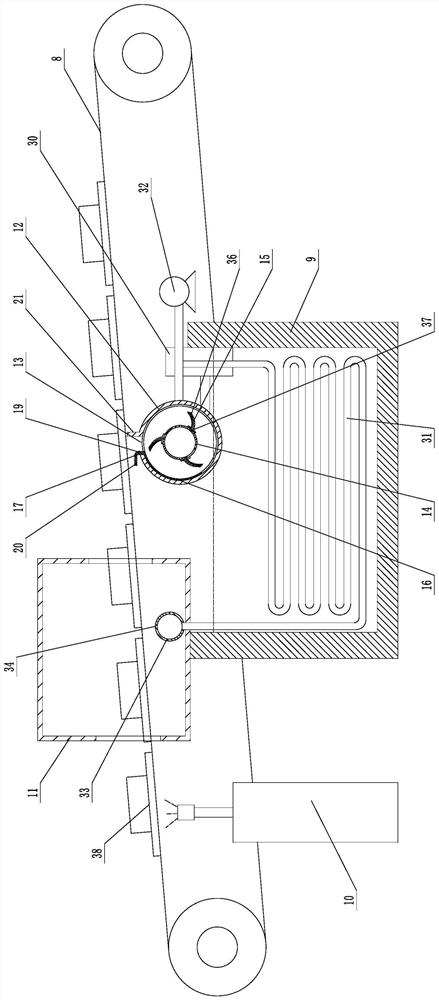

[0025] Example: DB one kind of a small PCB board connected to the plate structure (see attached figure 1 Attachment figure 2 ), A small plate comprising a DB 1, PCB board 2, the edges of the small plate is provided with DB extending outwardly projecting connecting portions 3, PCB board and the connecting portion is provided with a corresponding slot adapted 4, a plurality of spaced connecting portions 5 cheat pad, finger pad provided with a through-hole 6 at one end, the other end is provided with Goldfinger pad spacing between the edge portions of the connector, PCB pads to the slot edge and a correspondence set Goldfinger there are a number of lug 7, a connection portion inserted in the slot, finger pads expose the lower surface of the PCB through hole hidden in the slot, finger pads and the corresponding welding lug. DB embodiment a lower edge of the small plate of the present embodiment is provided with right and left connection portions each position, provided two gold finger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com