Two-component coating agent and coated-body protection method

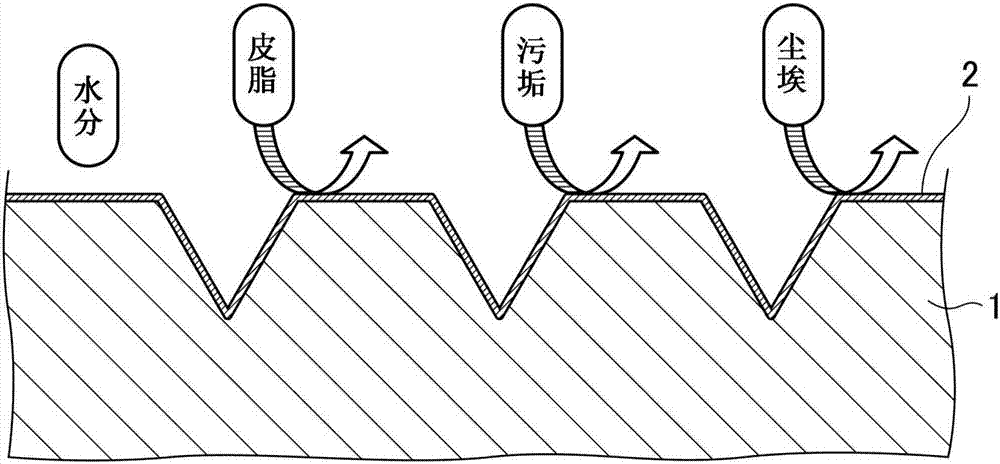

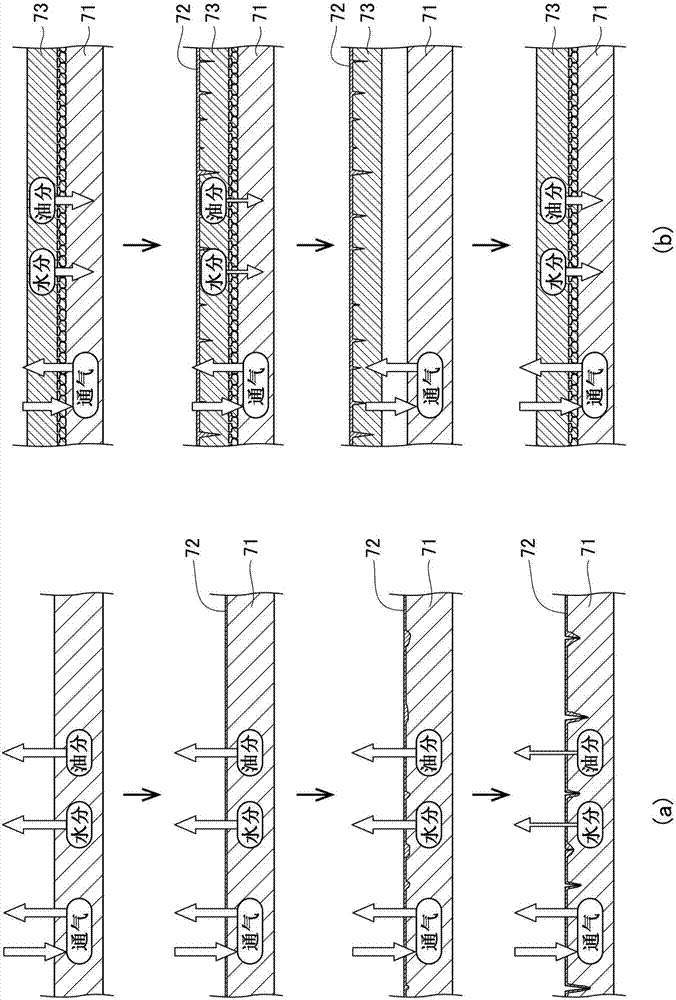

A coating agent, two-component technology, used in chemical instruments and methods, devices for coating liquids on surfaces, coatings, etc., to prevent the adhesion of dirt, prevent surface deterioration, and have excellent texture effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Specific examples to which the two-component coating agent of the present invention is applied will be described in detail below.

[0064] First, the main ingredients constituting the two-component coating agent and the curing agent were respectively combined to prepare samples of Examples 1 to 9 of the present invention and Comparative Examples 1 to 6 shown in Table 1 below.

[0065]

[0066] The main ingredient is prepared by adjusting the respective content ratios of acrylic resin, urethane resin, silicone, fluorine-containing water, and mineral oil. At this time, the proportion of the fluororesin contained in the fluorine-containing water was 10% by mass relative to the total mass of the fluorine-containing water. In addition, the curing agent is produced by adjusting the contents of isocyanate and carbodiimide compound contained therein. The proportion of the cross-linking component represented by carboimide compound contained in the curing agent is 38% to 42%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com