Polysilicon block bulk material weighing device

A weighing device, polysilicon technology, applied in the direction of packaging, to achieve the effect of avoiding surface deterioration, avoiding clogging, and avoiding metal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

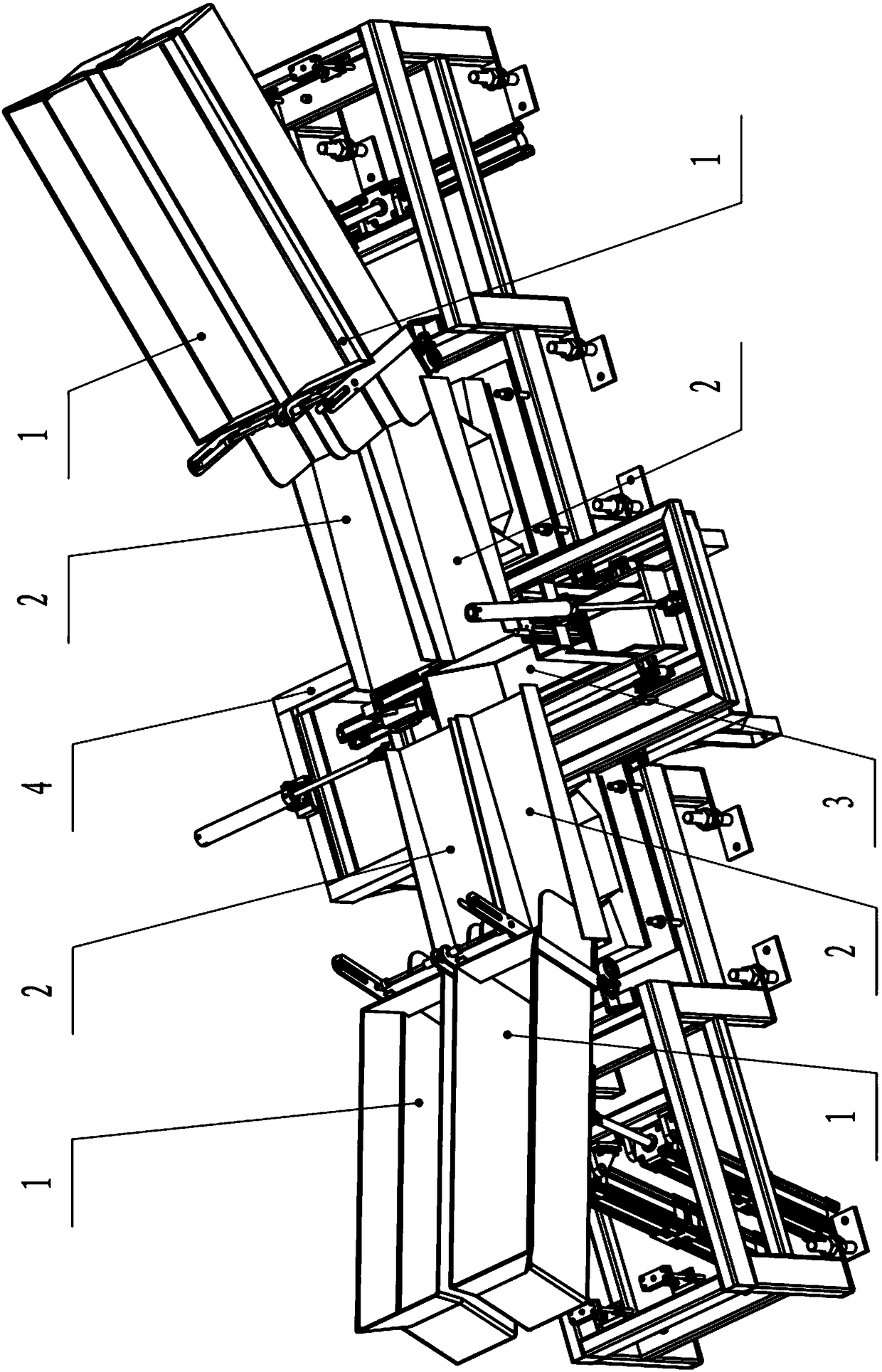

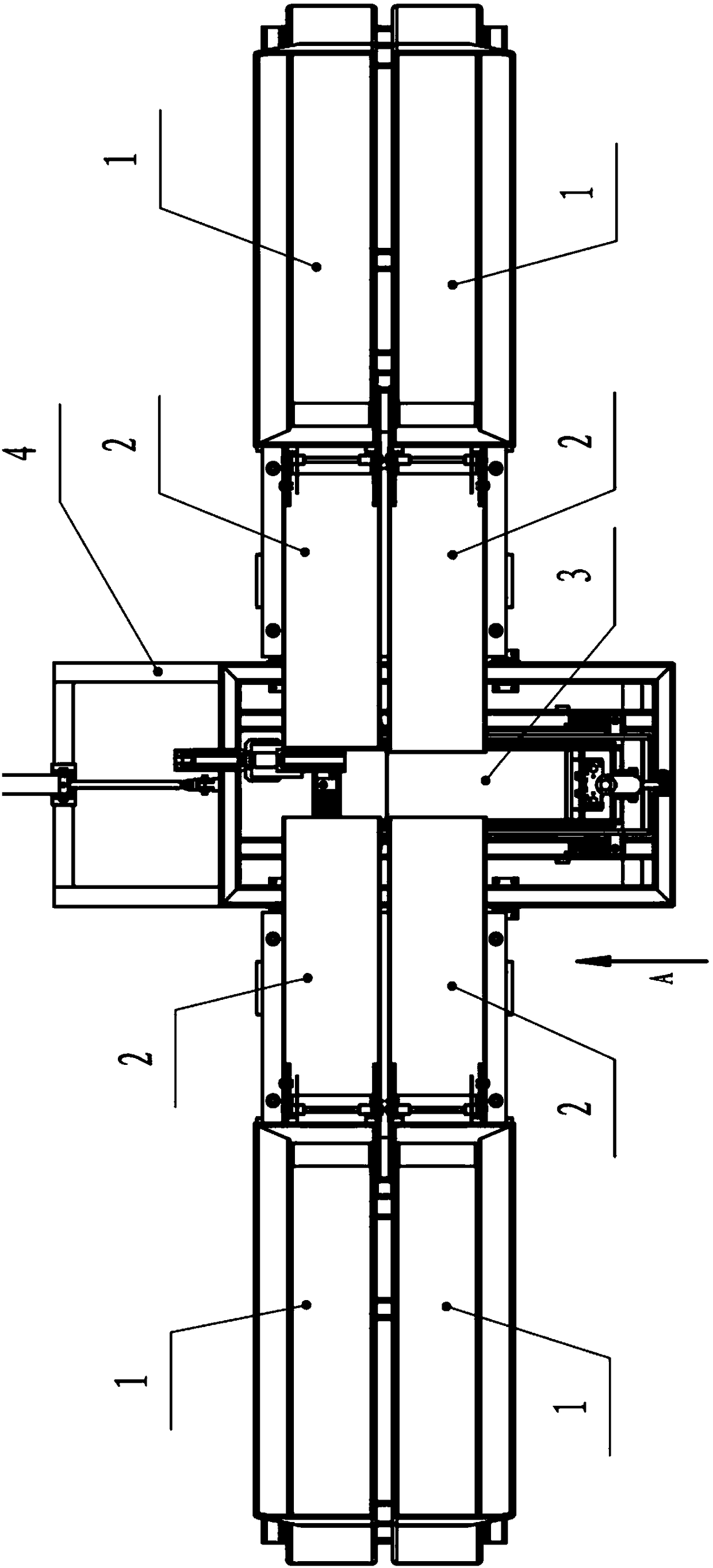

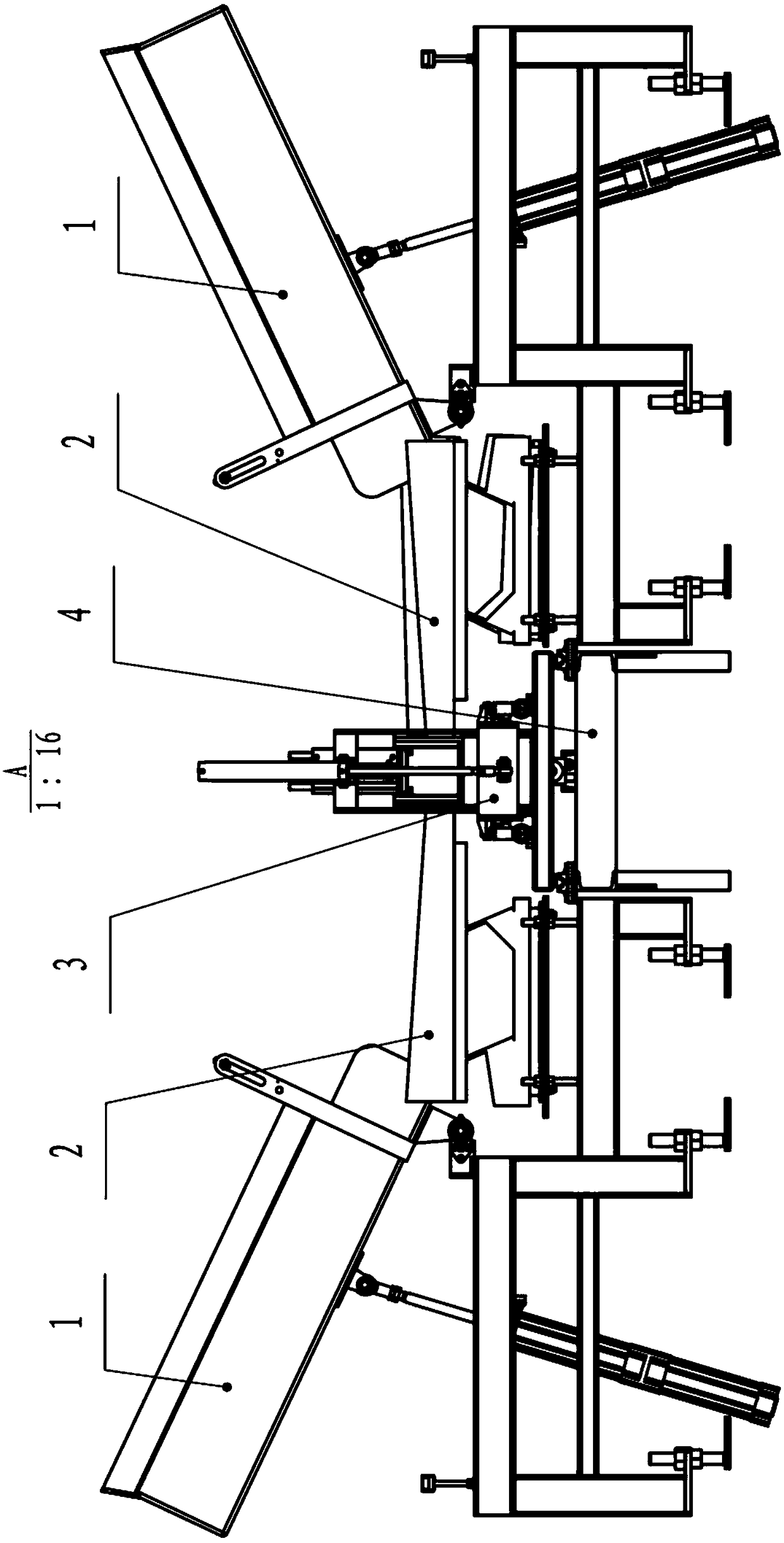

[0020] The specific embodiment of the present invention sees Figure 1 to Figure 6 , a polysilicon block bulk material weighing device, which includes a material storage mechanism 1, a vibrating feeder 2, a mobile weighing mechanism 3, a mobile support 4, and the mobile weighing mechanism 3 can be mounted on the mobile support 4 Move back and forth, the mobile weighing mechanism 3 is provided with a weighing trough 36, and the weighing trough 36 can swing downwards around the rear end, and the left and right sides of the mobile weighing mechanism 3 are respectively provided with two vibrating feeders 2, vibrating The rear end of the feeder 2 is provided with a material storage mechanism 1, and the material storage mechanism 1 is provided with a material storage tank 13, and the material storage tank 13 can swing upwards around the front end.

[0021] Above-mentioned material storage mechanism 1 comprises material storage frame 11, is provided with material storage tank 13 abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com