n-type III-nitride semiconductor material and preparation method thereof

A nitride semiconductor, n-type technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of surface morphology deterioration, hindering the growth of III-nitride materials, and reducing carrier concentration. Achieve the effect of avoiding surface deterioration, avoiding sample surface passivation and holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

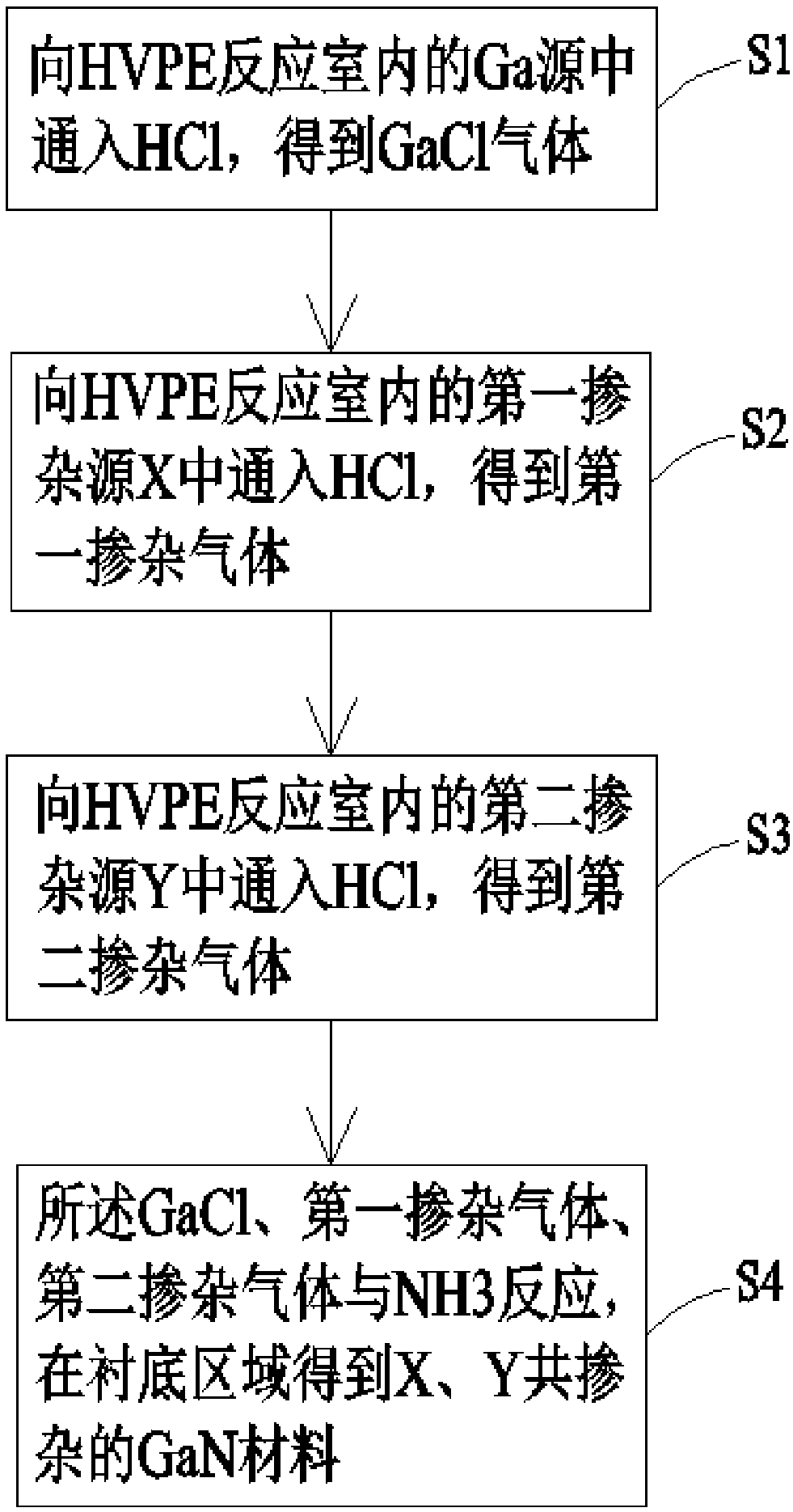

[0034] For the n-type III nitride semiconductor material doped with two dopants, the present invention provides a preparation method. The preparation method includes the following steps:

[0035] S1. Pass the reaction gas into the reaction chamber to react with the reaction source;

[0036] S2. Pass reaction gas into the first doping source X in the reaction chamber to obtain the first doping gas;

[0037] S3. Pass the reaction gas into the second doping source Y in the reaction chamber to obtain the second doping gas;

[0038] S4, the first doping gas, the second doping gas, and the product of the reaction gas and the reaction source and NH 3 After the reaction, an n-type group III nitride semiconductor material co-doped with X and Y is obtained in the substrate region.

[0039] Hereinafter, taking GaN as an example, the preparation method of the n-type III nitride semiconductor material is described in detail, which includes the following steps:

[0040] S1. Pour HCl into the Ga source...

Embodiment approach

[0046] As an embodiment, the first doping source X and the second doping source Y are selected from: Si, Ge, Sn, O, and S. Preferably, the first doping source X is Si, and the second doping source Y is Ge. At this time, the HVPE-based GaN material preparation method of the present invention adopts a multi-donor co-doping method to prepare the GaN material. In the process of HVPE growth of GaN, source gas containing Si impurities and Ge impurities are simultaneously introduced to generate n-type GaN co-doped with Si and Ge. Therefore, the concentration of the Si impurity source gas and Ge impurity source gas in the gas phase is lower than the lower limit of Si doping passivation and Ge doping holes, respectively, so that the sample morphology is not deteriorated, and the two are generated inside the GaN material The sum of the carrier concentration can meet the requirements of the device for the carrier concentration of the substrate.

[0047] Further, when the first doping sour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com