Method for pulse chemical vapor deposition of Al2O3 film layer

A chemical vapor deposition and film technology, which is applied in chemical instruments and methods, chemical/physical processes, gaseous chemical plating, etc. Avoid surface deterioration and crystal form transformation, process safety and control, and facilitate the effect of vapor deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Pulse Chemical Vapor Deposition of Al 2 o 3 Film layer for surface modification of TiO 2 Catalyst, the specific process is as follows:

[0051] In this embodiment, a fixed-bed reactor with a volume of 4.1 L is used for the pulse chemical vapor deposition process.

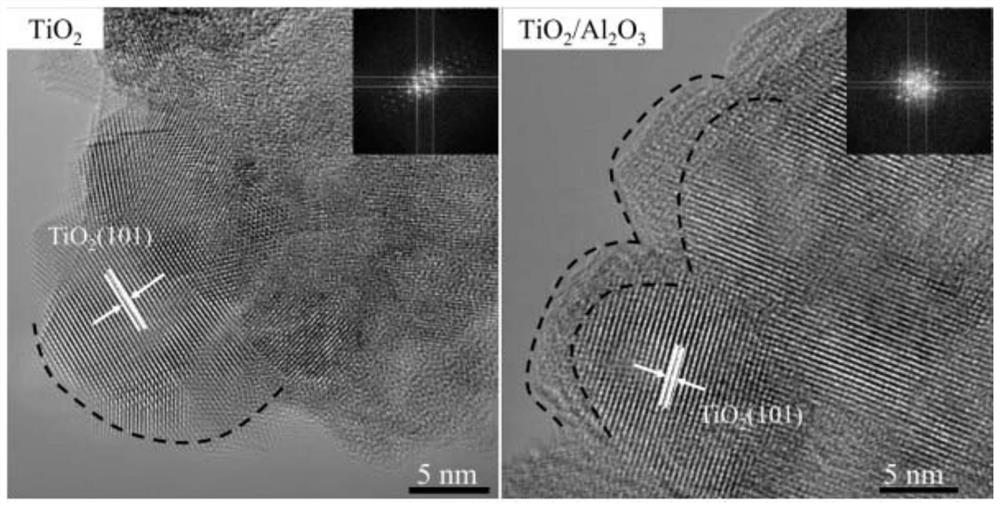

[0052] Uncoated TiO 2 The average diameter of the catalyst particles is 30 nm.

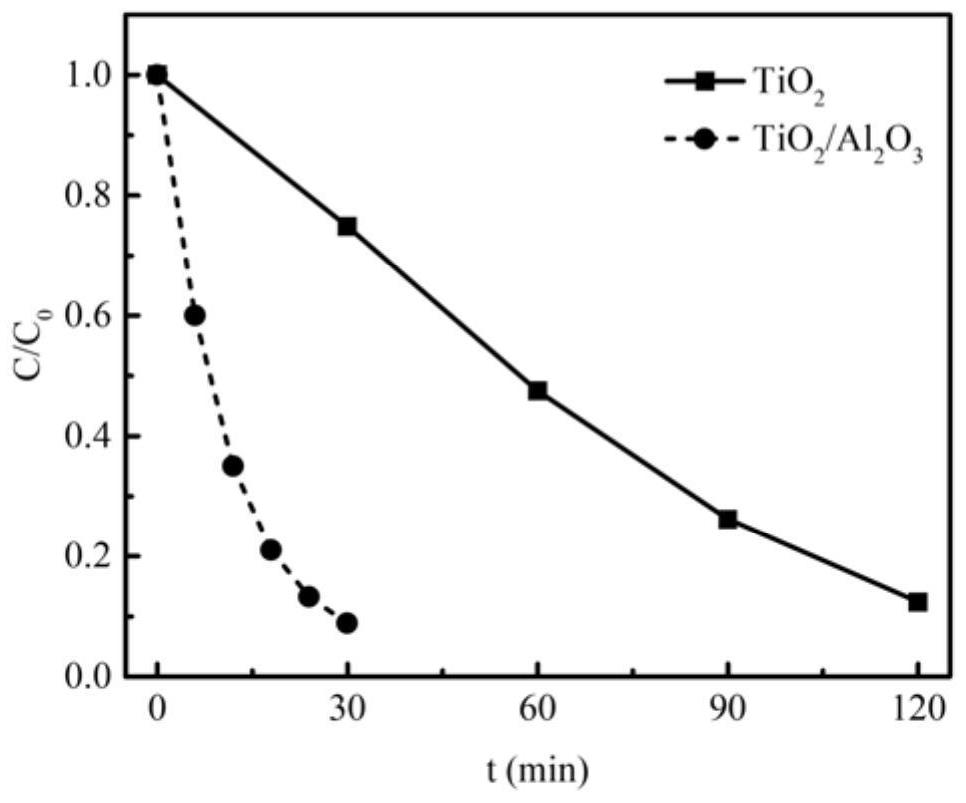

[0053] Pulse Chemical Vapor Deposition of Al 2 o 3 Film layer for surface modification of TiO 2 Catalysts to improve TiO 2 The effect of photocatalytic degradation of organic pollutants, including the following steps:

[0054] (1) Pretreatment: 0.6g uncoated TiO 2 The catalyst was dispersed on the porous distribution plate built in the reactor, and dried at 120 °C for 2 h, and the TiO 2 Carry out heating pretreatment.

[0055] (2) Clearing: 0.5g precursor AlCl 3 Place at the bottom of the reactor, seal the reactor, and then evacuate to remove the air in the reactor.

[0056] (3) The first half-reaction: the reactor i...

Embodiment 2

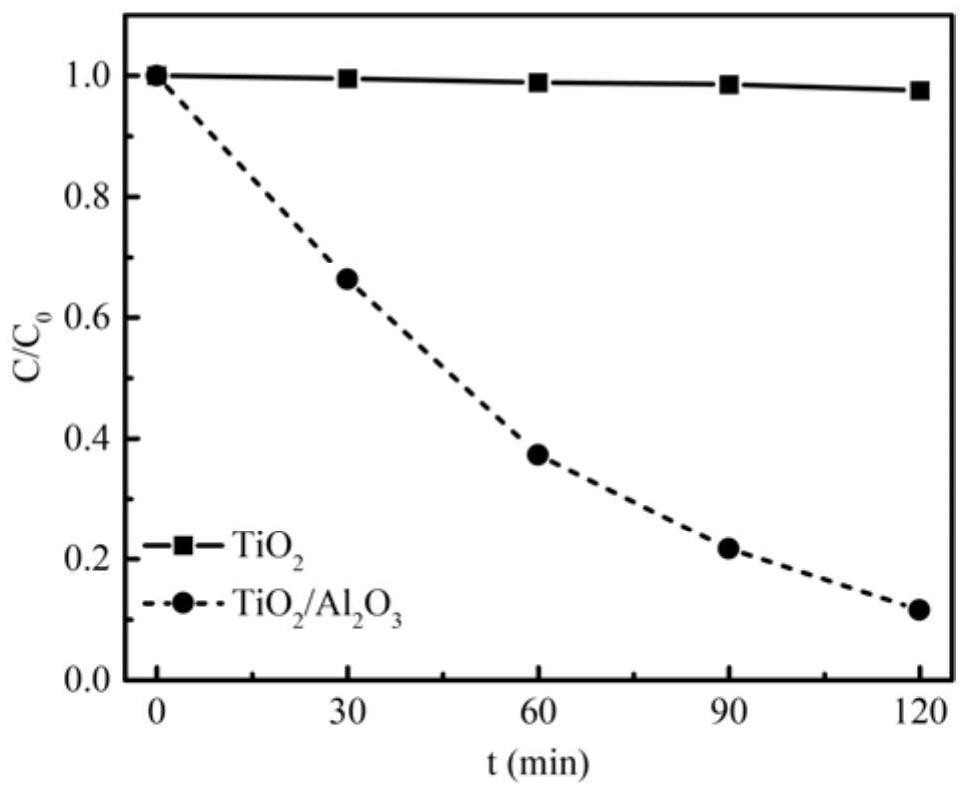

[0065] Pulse Chemical Vapor Deposition of Al 2 o 3 Film layer for surface modification of TiO 2 Pigment, the specific process is as follows:

[0066] In the already coated SiO 2 TiO 2 The surface of the pigment, then deposit Al by the method in the present invention 2 o 3 Floor.

[0067] Uncoated TiO 2 The particle size of the pigment is 100-250nm.

[0068] Pulse Chemical Vapor Deposition of Al 2 o 3 Film layer for surface modification of TiO 2 Pigment, and pigment is applied in water-based paint, investigates its weatherability, comprises the following steps:

[0069] (1) Pretreatment: 0.6gTiO 2 / SiO 2 The pigment is dispersed on the porous distribution plate built in the reactor, dried at 120°C for 2 hours, and the pigment is pretreated by heating.

[0070] (2) Clearing: 0.5g precursor AlCl 3 Place at the bottom of the reactor, seal the reactor, and then evacuate to remove the air in the reactor.

[0071] (3) The first half-reaction: the reactor is heated to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com