Multifunctional device pin tailoring tool and application method

A component and multi-functional technology, applied in the field of multi-functional component pin cutting tooling, can solve the problems of excessive lead cutting size, lead bending deformation, internal damage of the device, etc., achieving wide practicability and eliminating impact stress. , high consistency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, mechanism feature and use effect of the present invention will be further described.

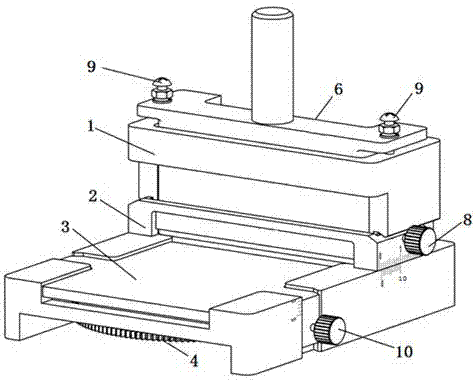

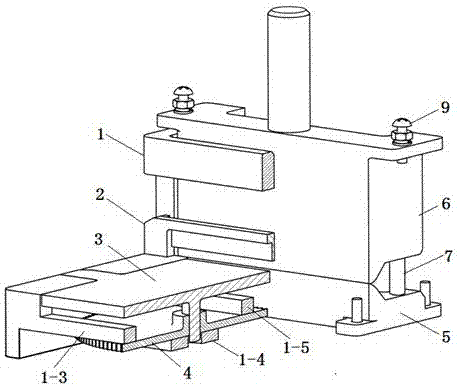

[0030] like Figure 1 to Figure 10 As shown, a multifunctional component pin cutting tool includes a base 1, a positioning plate 2, a lifting table 3, a driving wheel 4, a lower cutter 5, an upper cutter 6, a guide column 7, a locking screw Ⅰ 8, and a limit screw 9. Lock screw Ⅱ10.

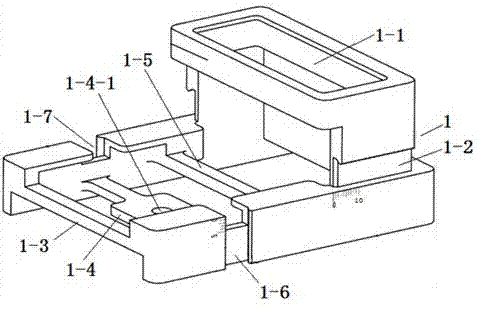

[0031] The lower end of the base 1 is a rectangular frame structure, and the top of the rear frame of the base 1 is two vertical walls, and above the two vertical walls is a rectangular upper tool hole 1-1, the upper tool hole 1-1 communicates with the frame of the base 1, and the two vertical walls The part where the outer surface is in contact with the frame of the base 1 is a concave surface Ⅰ1-2. On the frame surface of the base 1 below the concave surface Ⅰ1-2 of one vertical wall, there is a ten-degree marking ruler horizontally. The 0 scale line and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com