Hollow slab extrusion molding machine

A hollow board and forming machine technology, which is applied in the direction of objects with hollow walls, other household appliances, household appliances, etc., can solve the problems of uneven stability of the board and easy deformation of the hollow board, and achieve excellent stability. The effect of uniform and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

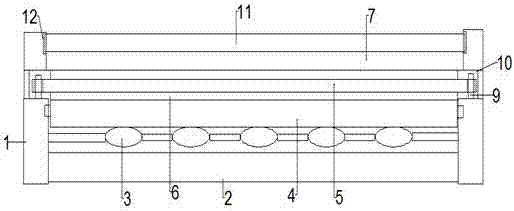

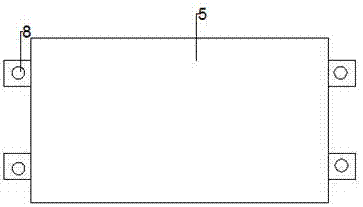

[0015] see figure 1 and figure 2 , the present invention provides a technical solution: a hollow plate extrusion molding machine, comprising a thermoforming box 1, a cold circulation box 2 and a cold cutting box 3, the upper end of the thermoforming box 1 is provided with a urea-formaldehyde resin inlet 9 and an adhesive agent inlet 10, and an exhaust port 7 is fixedly installed between the urea-formaldehyde resin inlet 9 and the adhesive inlet 10, and a hollow plate extrusion die 8 is arranged inside the thermoforming box 1, and the hollow plate extrusion die 8 Die extruding hole 16 is arranged inside, and electrical box 11 is installed on the right side of described thermoforming box 1, and the side of electrical box 11 is connected with reduction box 14, is installed between electrical box 11 and reduction box 14 and is equipped with wood. A hopper 13, a water inlet pipe 5 is installed on the upper end of the cold circulation box 2, and a water outlet pipe 6 is provided b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com