Automobile steering knuckle structure and machining process thereof

A technology of automobile steering knuckle and processing technology, which is applied in the field of automobile steering knuckle structure and processing technology, which can solve problems such as unstable quality of automobile steering knuckle and affect safety, and achieve easy automatic production, improve safety, and improve wear resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

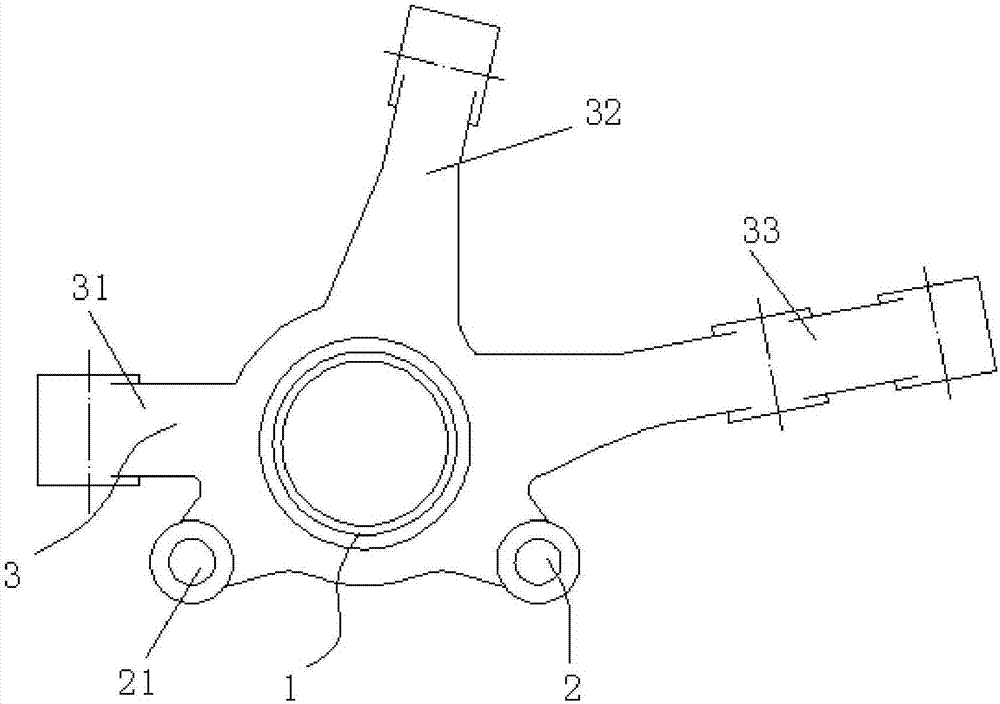

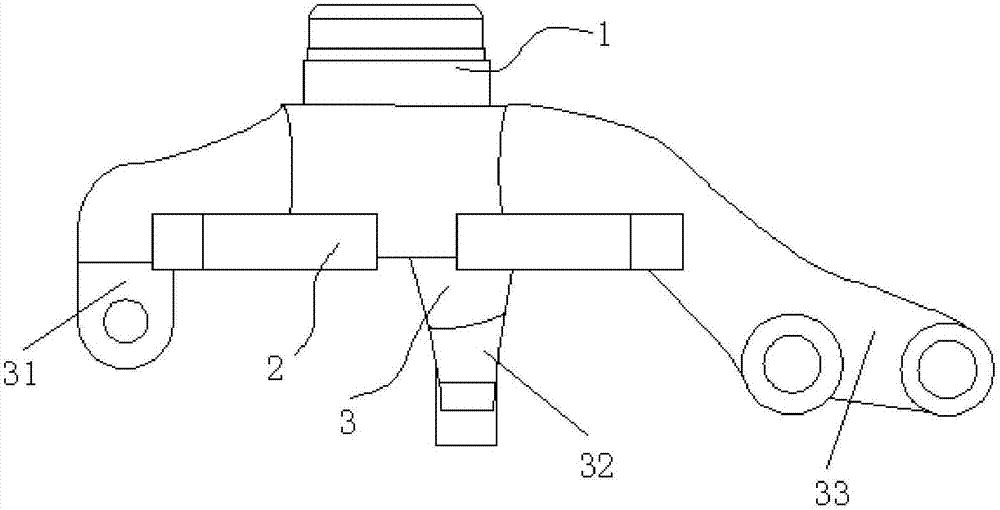

[0021] figure 1 with figure 2 The specific embodiment of the present invention is shown: an automobile steering knuckle structure, including a support journal 1, a flange 2 and a fork 3, and the support journal 1, flange 2 and fork 3 are integrally forged, The fork frame 3 is composed of a lower swing arm connection pair 31 , a steering push rod connection pair 32 and an upper swing arm connection pair 33 .

[0022] In this embodiment, the flange 2 is provided with two installation and fixing holes 21 .

[0023] In this embodiment, the surface of the automobile steering knuckle structure is coated with a wear-resistant metal coating.

[0024] The automobile steering knuckle adopts a forging process, including the following process steps:

[0025] 1) Material detection: rapid detection of the composition of the material before cutting;

[0026] 2) Cutting: Choose a high-speed sawing machine for cutting, and adopt the cutting method of rotary shearing;

[0027] 3) Heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com