A kind of high extension sound insulation two-component water-based waterproof coating and preparation method thereof

A waterproof coating, two-component technology, applied in the direction of coating, etc., can solve the problems of attenuation of waterproof coating extension performance, small accumulation density of fly ash, affecting waterproof effect, etc., and achieve the effect of reducing oil absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

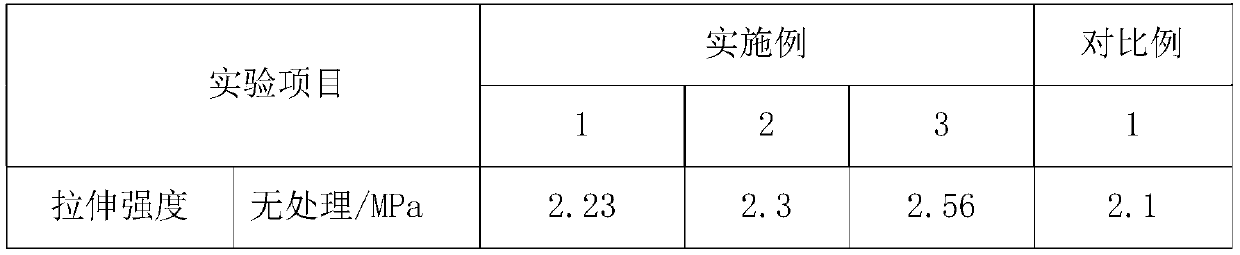

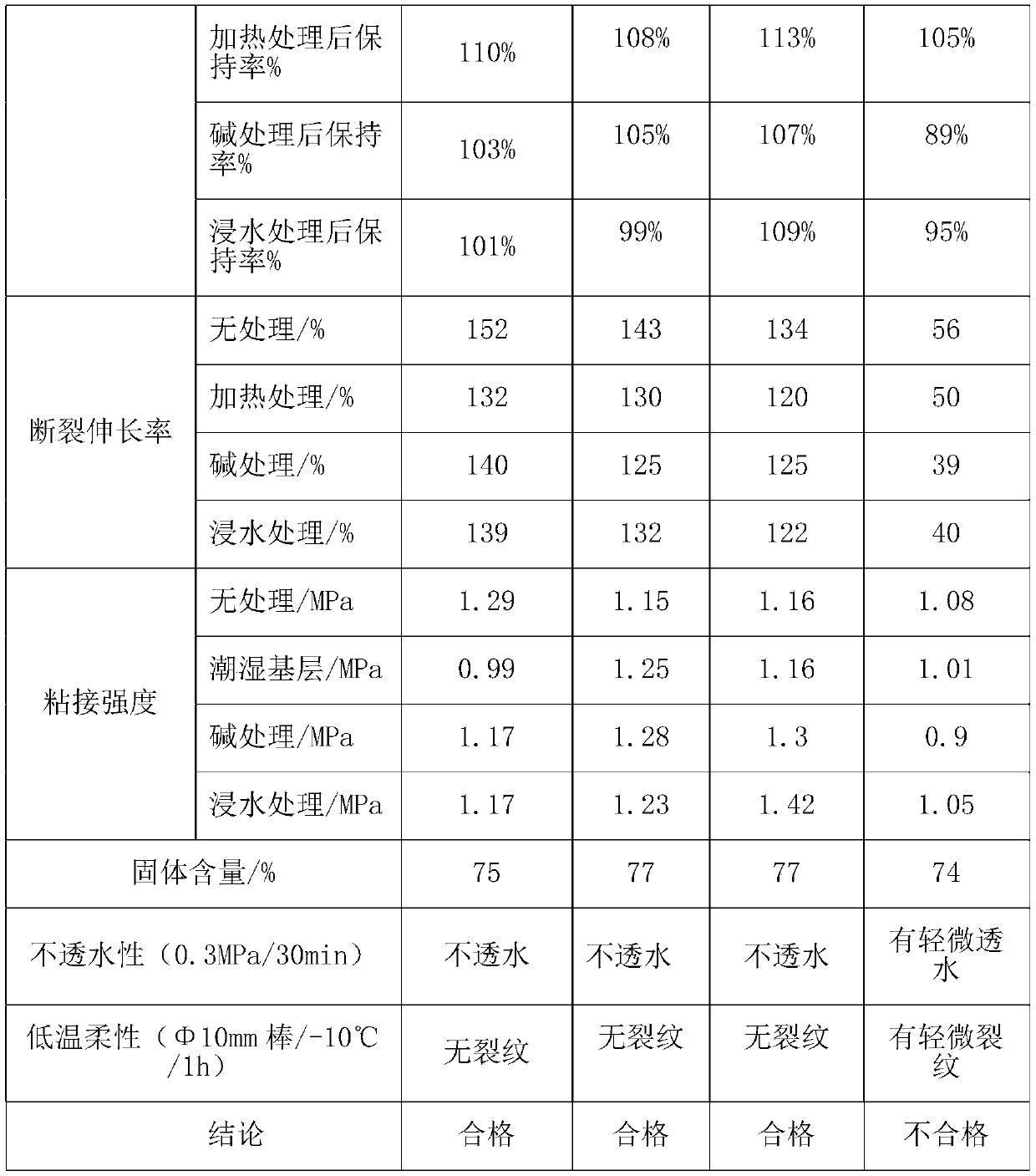

Embodiment 1

[0031] Prepare the raw materials of the liquid material according to the formula: 900g of VAE emulsion, 15g of defoamer, 1g of antifungal agent, and 100g of water; choose a stirring container that can be connected to a vacuum pump to vacuumize, and add the above-mentioned VAE emulsion, defoamer, and antimold to the container in sequence agent and water, close the feeding port, turn on the vacuum pump to vacuumize, control the stirring speed in the container to 350r / min, reduce the stirring speed to 150r / min after continuous stirring for 15 minutes, turn off the stirring after continuous stirring for 10 minutes, turn off the vacuum pump, and obtain the liquid material;

[0032] Prepare powder raw materials according to the formula: gray cement 500g, sodium hydroxide powder 30g, 325 mesh quartz powder 100g, water reducing agent 20g, fly ash 200g; add fly ash and sodium hydroxide to the filler pre-dispersion mixing equipment, Turn on the stirring at a speed of 1000r / min, pre-disp...

Embodiment 2

[0034] Prepare the raw materials of the liquid material according to the formula: 900g of VAE emulsion, 20g of defoamer, 1g of antifungal agent, and 100g of water; choose a stirring container that can be connected to a vacuum pump, and add the above-mentioned VAE emulsion, defoamer, and antimold to the container in sequence agent and water, close the feeding port, turn on the vacuum pump to vacuumize, control the stirring speed in the container to 350r / min, reduce the stirring speed to 150r / min after continuous stirring for 15 minutes, turn off the stirring after continuous stirring for 10 minutes, turn off the vacuum pump, and obtain the liquid material;

[0035] Prepare powder raw materials according to the formula: gray cement 600g, sodium hydroxide powder 20g, 325 mesh quartz powder 150g, water reducing agent 15g, fly ash 300g; add fly ash and sodium hydroxide to the filler pre-dispersion mixing equipment, Turn on the stirring at a speed of 1000r / min, pre-disperse and stir...

Embodiment 3

[0037] Prepare the raw materials of the liquid material according to the formula: 900g of VAE emulsion, 20g of defoamer, 1g of antifungal agent, and 100g of water; choose a stirring container that can be connected to a vacuum pump, and add the above-mentioned VAE emulsion, defoamer, and antimold to the container in sequence agent and water, close the feeding port, turn on the vacuum pump to vacuumize, control the stirring speed in the container to 350r / min, reduce the stirring speed to 150r / min after continuous stirring for 15 minutes, turn off the stirring after continuous stirring for 10 minutes, turn off the vacuum pump, and obtain the liquid material;

[0038] Prepare powder raw materials according to the formula: gray cement 700g, sodium hydroxide powder 20g, 325 mesh quartz powder 150g, water reducing agent 15g, fly ash 200g; add fly ash and sodium hydroxide to the filler pre-dispersion mixing equipment, Turn on the stirring at a speed of 1000r / min, pre-disperse and stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com