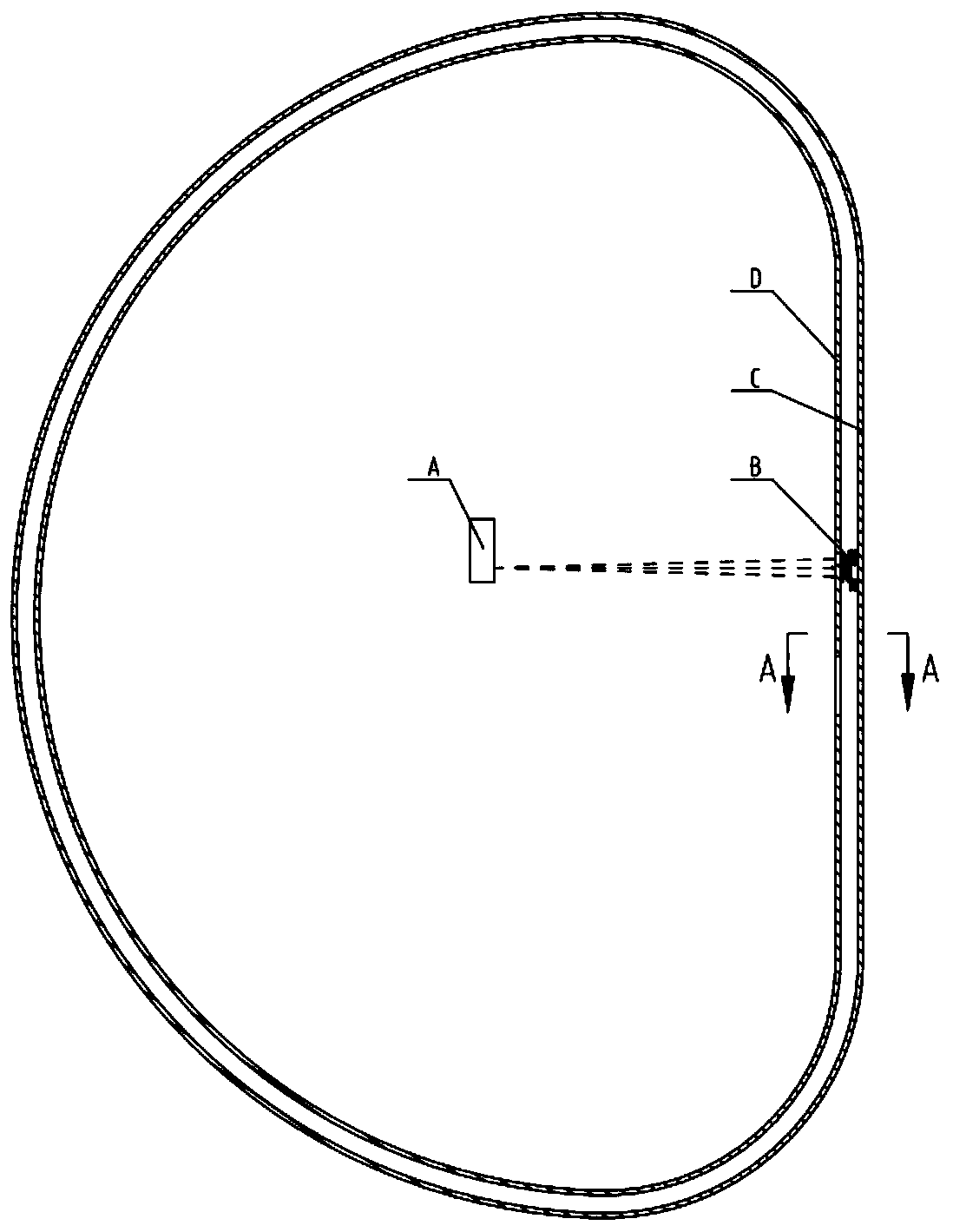

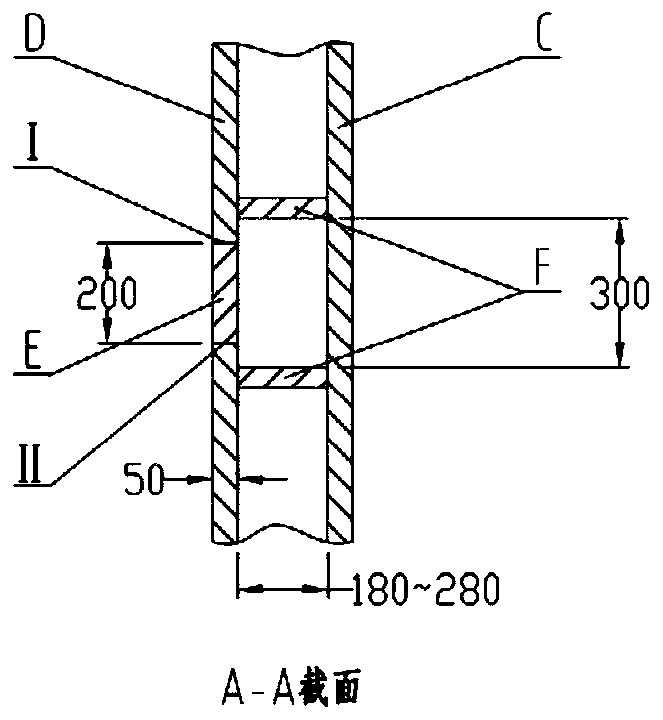

Internal automated flaw detection system for nuclear power rectangular variable cross-section pipelines

A variable cross-section, rectangular technology, applied in the direction of pipe components, special pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of high wall flatness, stainless steel, non-ferromagnetic materials, uneven unevenness, and guarantee Detection effect, meet the change of detection space, and reduce the effect of overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

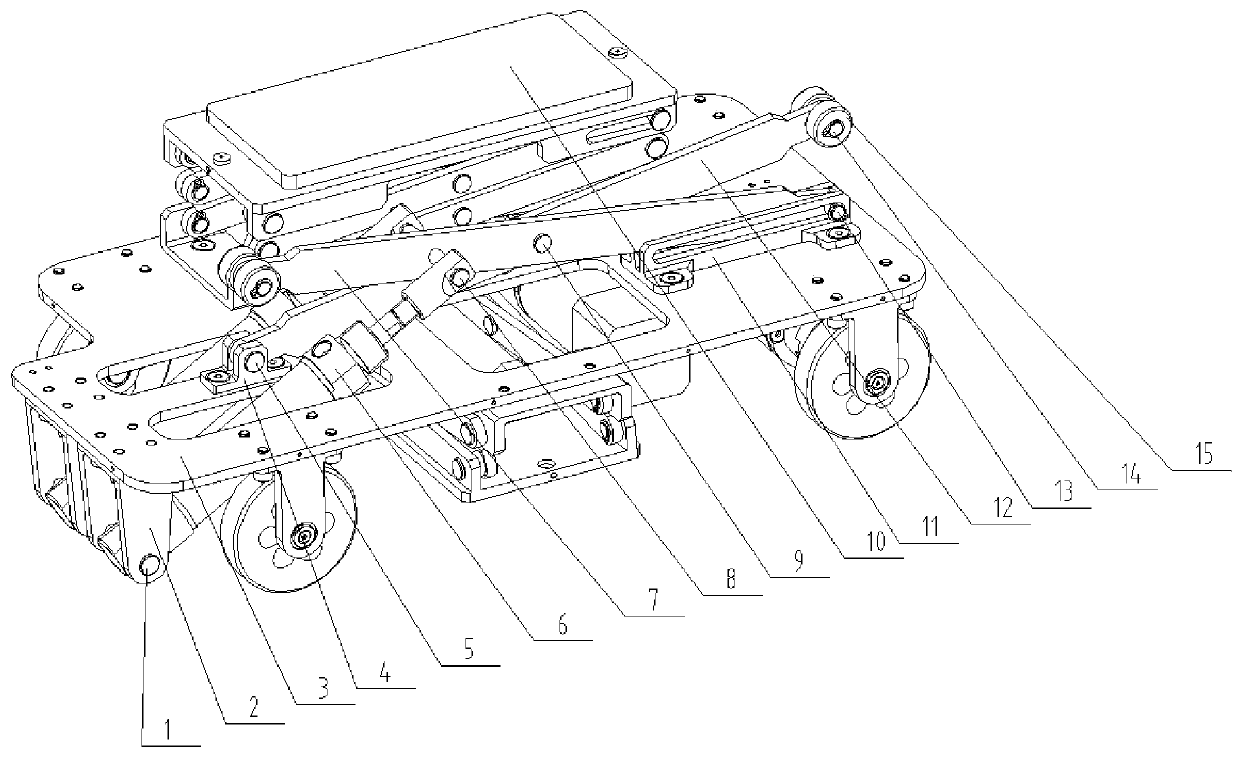

[0034] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

[0035] The internal automatic flaw detection system of the nuclear power rectangular variable cross-section pipeline includes

[0036](1) positioning system; the positioning system is used to accurately locate the position of the film, and provides target orientation for the ray source machine. It is composed of two magnets 25, sensors 42, and sound and light alarms 43 fixed on the fixed plate of the dark bag. A group of positioning systems are respectively arranged on the dark bag fixing plate 24 and the transverse dark bag fixing plate 45 . When the fabric mechanism is stretched out, the film is close to the weld seam, and the magnet 25 is close to the weld seam, the sensor 42 can accurately locate the magnet 25 at an interval of 50 mm thick stainless steel 316L, and the sound and light alarm 43 sends out an audible and visual alarm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com