Spring length detection control method and detection control system

A detection and control system and detection and control technology, applied in measuring devices, instruments, electrical devices, etc., can solve problems such as affecting efficiency, accuracy, high heat dissipation system, and many tolerance errors, and improve the efficiency and accuracy of zero adjustment. Digitalization High degree and improve the effect of compensation mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

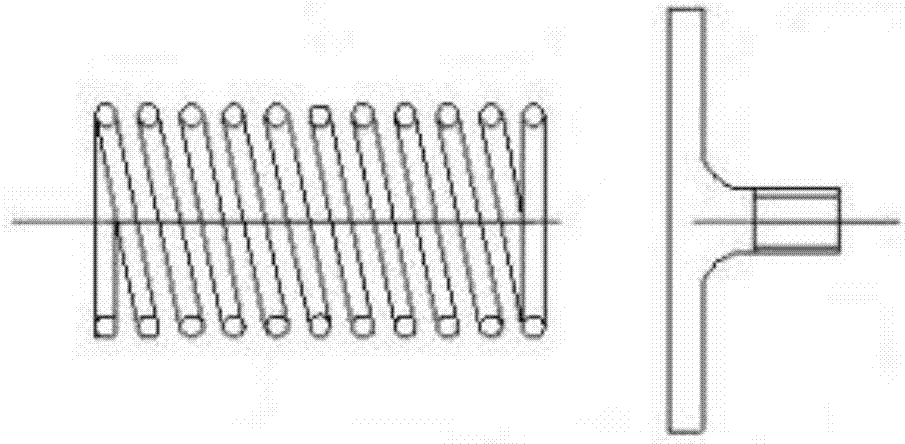

[0037] A spring length detection control system, such as figure 1 As shown, including non-contact detection probe, conditioning amplifier circuit, multi-level processing circuit, A / D conversion circuit, embedded microcontroller (ie embedded MCU), output signal processing circuit, temperature and humidity detector outside the chassis, inside the chassis Temperature and humidity detector, the temperature and humidity detector outside the chassis is used to compensate the measurement error caused by the probe with the change of ambient temperature and humidity, and the temperature and humidity detector inside the chassis is used to compensate the measurement error caused by the electronic components in the chassis with the change of temperature and humidity. The non-contact detection probe is sequentially connected to the conditioning amplifier circuit, the multi-stage processing circuit, the A / D conversion circuit, and the embedded microcontroller, and the embedded microcontrolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com