A stress-strain test method for a metal hydride hydrogen storage tank

A stress-strain test and test method technology, applied in the direction of measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of increased tank expansion, hydrogen storage tank increase, hydrogen storage tank failure, etc., to achieve simple operation , Efficient evaluation method, accurate effect of test point selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

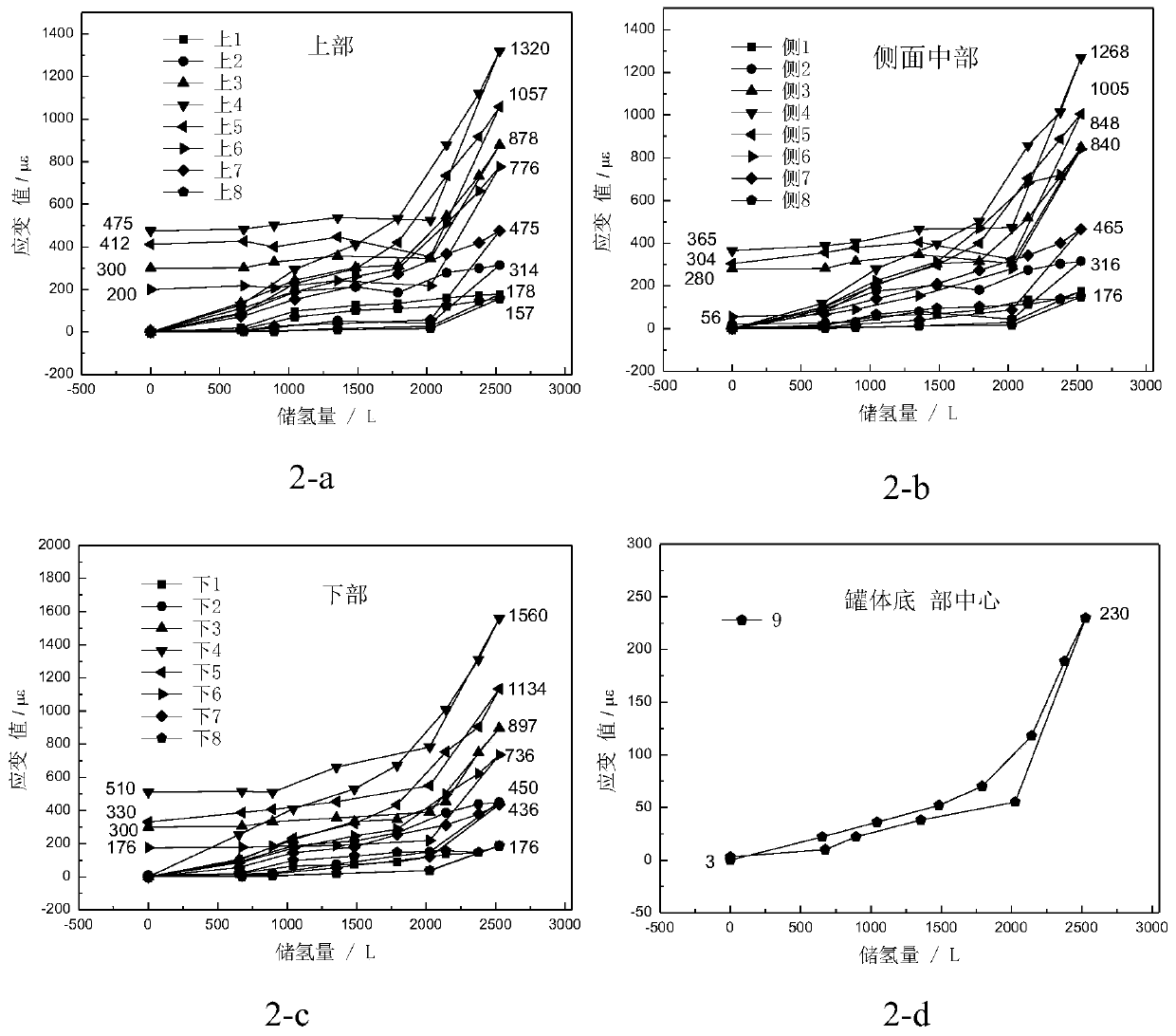

[0031] The application environment of the stainless steel metal hydride hydrogen storage tank is a 25°C water bath environment, placed horizontally. The length of the straight section of the hydrogen storage tank is H=330mm, the inner diameter r=125mm, and the outer diameter d=133mm. The hydrogen storage tank is filled with XY 2 Type hydrogen storage alloy, the alloy filling rate is 54%, the total hydrogen storage capacity is about 2500L, and the rated working pressure is 4MPa.

[0032] Stress-strain testing of stainless steel metal hydride hydrogen storage tanks involves the following steps:

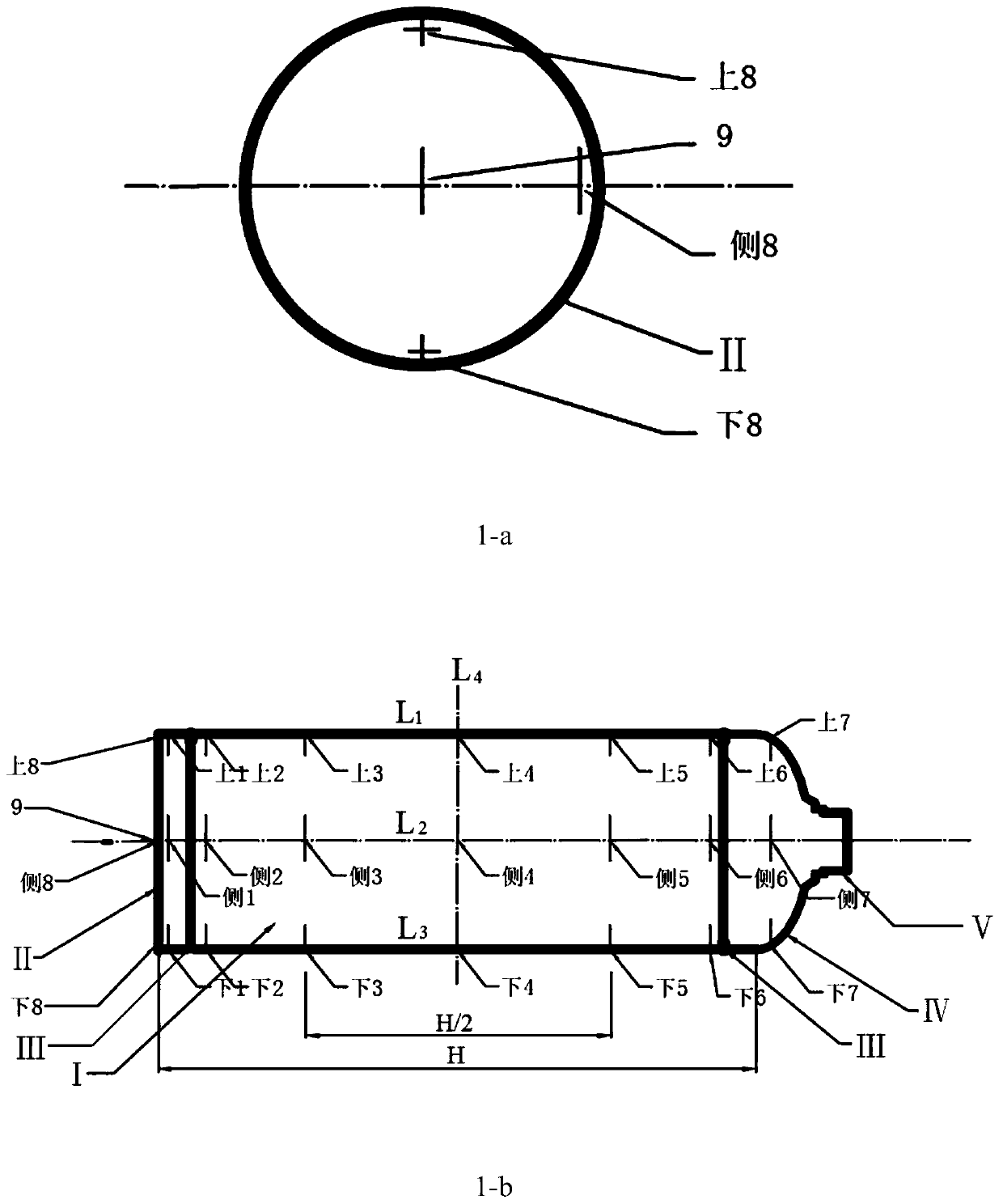

[0033] (1) Select the strain point of the test

[0034] Place the hydrogen storage tank horizontally, specifically as figure 1 As shown in -b, draw a straight line L on the upper part, the middle part and the lower part of the side along the axial direction of the hydrogen storage tank 1 , L 2 , L 3 , and then draw a straight line L perpendicular to the axial direction at the cente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com