Space error decoupling compensation method for numerically controlled worm grinding wheel gear grinding machine

A technology of worm grinding wheel and compensation method, which is applied in the direction of program control, computer control, general control system, etc., and can solve the problems that a unified and effective machine tool error decoupling compensation method has not yet been formed, and the theory is not very mature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0042] Taking the YW7232 CNC worm wheel gear grinding machine produced by a certain factory as the research object, the present invention will be further described in detail in conjunction with the accompanying drawings and specific implementation methods.

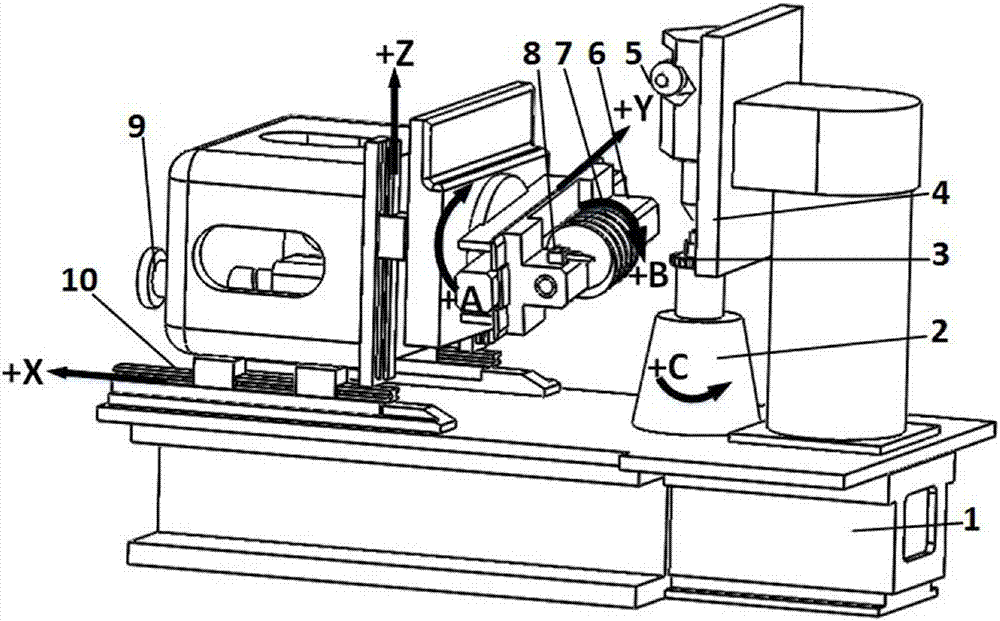

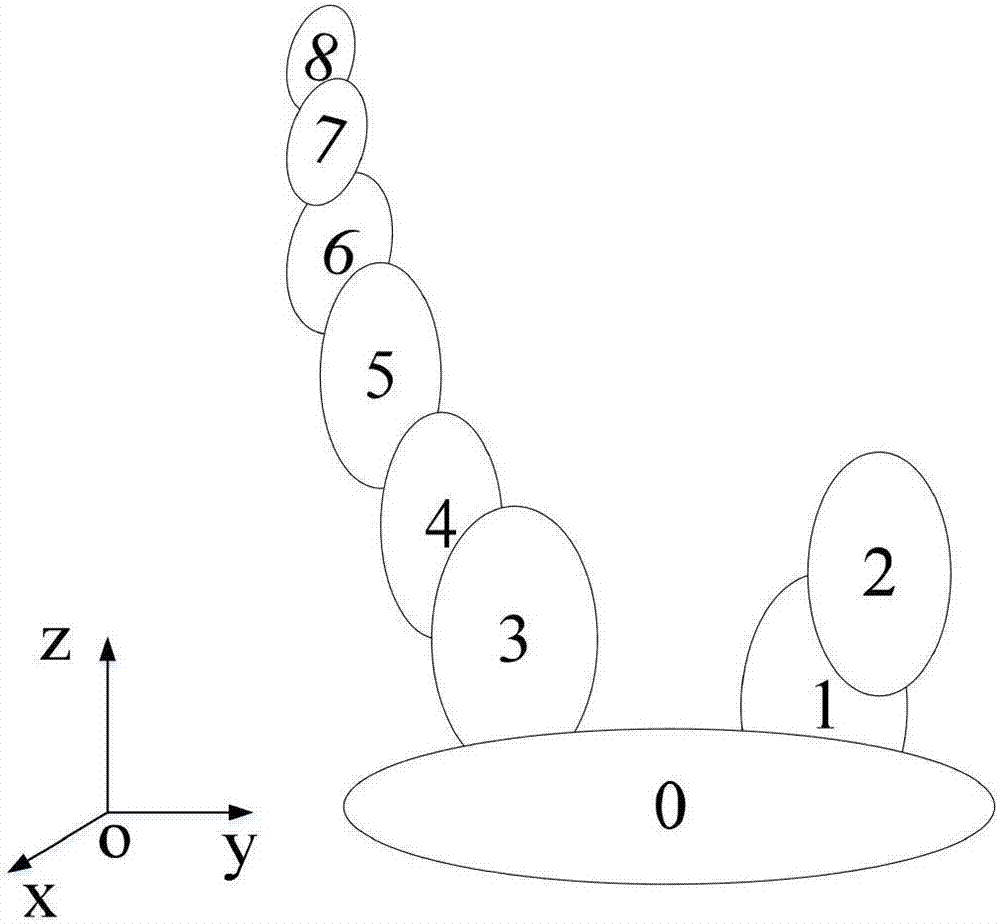

[0043] Such as figure 1 , 2 As shown, a spatial error decoupling compensation method of CNC worm gear grinding machine, the structural analysis and motion analysis of CNC worm gear grinding machine, the 41 geometric error elements of the machine tool are obtained as shown in the following table:

[0044] All geometric error elements of the machine tool are as follows, a total of 41 geometric error elements, including 30 position-related errors and 11 position-independent errors.

[0045]

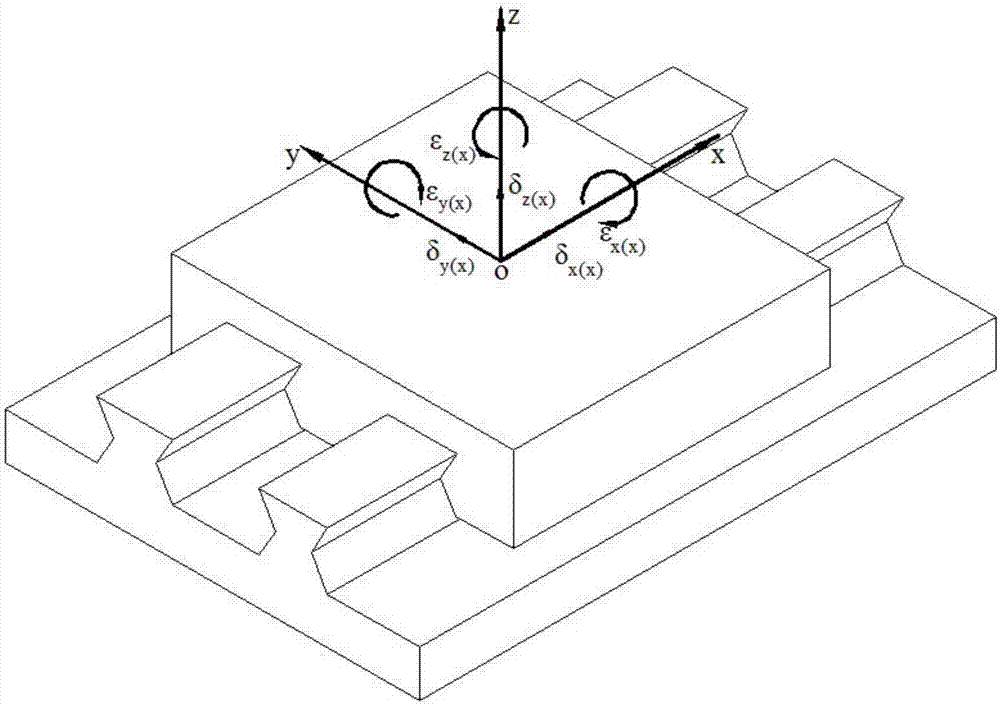

[0046] (Taking the X-axis and C-axis as examples to illustrate the meanings of position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com