Construction site operation safety remote management and control system and method

A construction site and management and control system technology, applied in the direction of instruments, data processing applications, resources, etc., can solve problems such as effective management and control, power supply enterprises have not been established, and risk assessment databases have not been established, so as to reduce work carrying capacity and save human and material resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

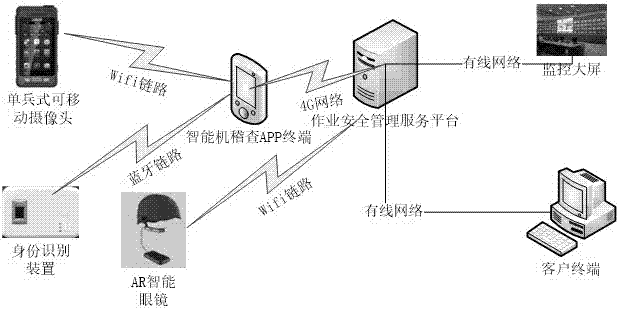

[0042] Front-end systems include:

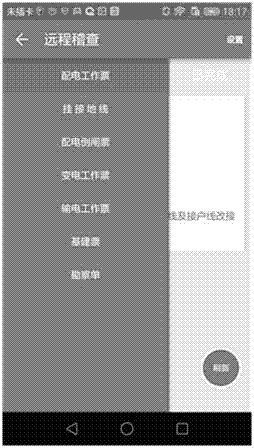

[0043] 1) Handheld terminal device: Android system-based intelligent terminal customized application software, according to the operation process, take pictures of on-site personnel sign-in, risk points, and safety measures, and the photos will be automatically uploaded to the operation site safety and quality control platform when the network is smooth.

[0044] 2) Individual equipment: For small-scale scattered operation sites, individual equipment can record the scene in real time through fixed erection and realize real-time audio intercom with the monitoring center. Realize the automatic upload function of offline recording video when charging.

[0045] 3) AR smart glasses equipment: For small-scale scattered on-site operations such as distribution network operations, through the video transmission function of the AR smart glasses system, the real-time picture of the job site can be transmitted to the supervision and command center from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com