Method for prolonging shelf life of milk

A technology of shelf life and milk, applied in the preservation of milk, dairy products, applications, etc., can solve problems such as extending the shelf life of milk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

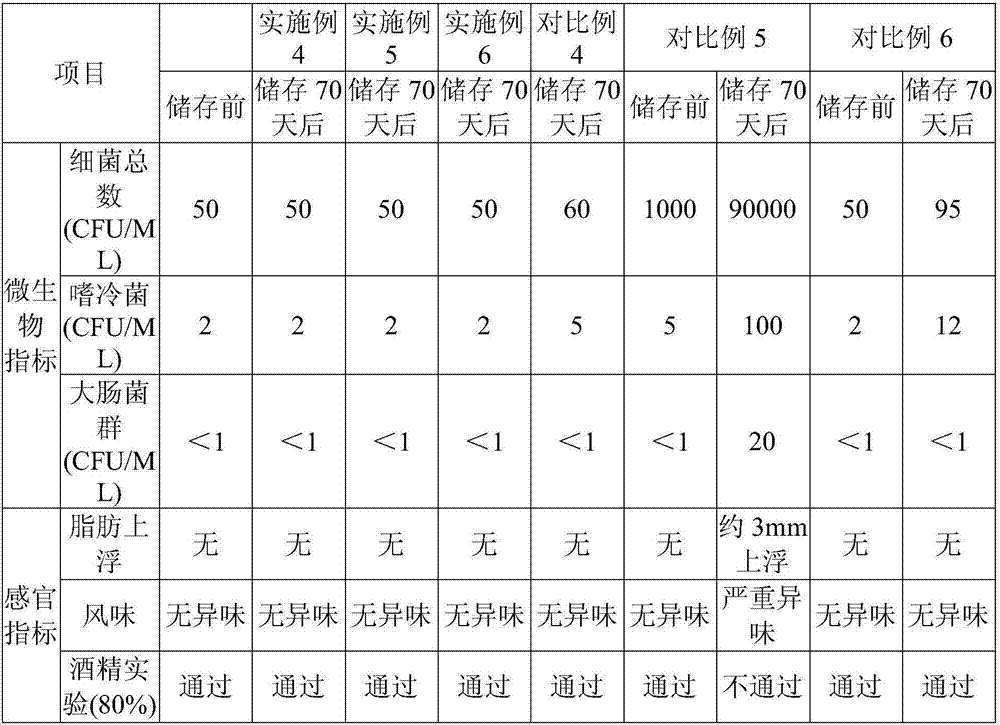

Examples

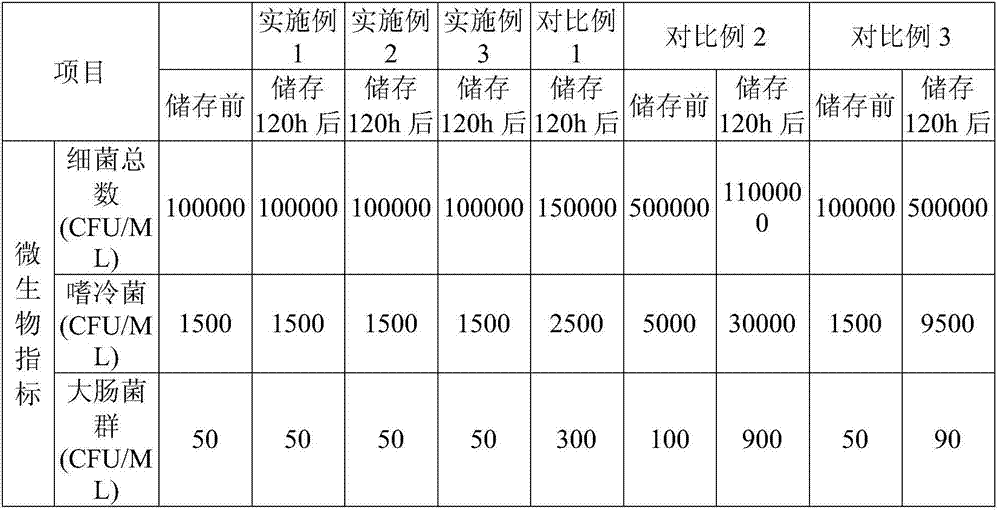

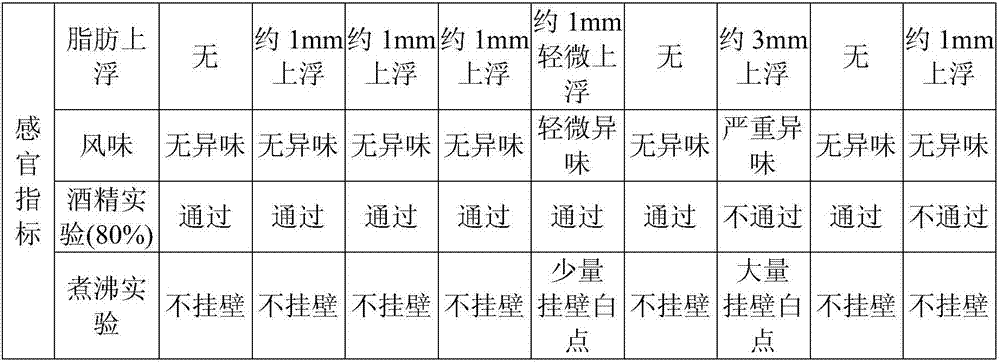

Embodiment 1

[0017] The raw milk at about 37°C just extruded from the pasture is rapidly cooled to 0°C within 1-2 minutes through a high-efficiency plate heat exchanger. The total number of raw milk bacteria is 100,000 CFU / ML, and then the raw milk is quickly stored in a sterile , airtight, airtight, and light-tight container (the volume of raw milk in the container should exceed 95% of the total volume), and then fill nitrogen in the aseptic, airtight, airtight, and light-proof container to ensure that the inside of the container The residual oxygen content is below 0.2v% and the pressure in the container is above 0.5MPa, then stored at 0°C for 120 hours, and the microbial indicators (total number of bacteria, psychrophilic bacteria, coliform group) and sensory indicators (fat floating, flavor) of raw milk are observed. , alcohol test, boiling test).

Embodiment 2

[0019] It is basically the same as Example 1, except that the raw milk at about 37°C just extruded from the pasture is rapidly cooled to 1°C within 1-2 minutes through a high-efficiency plate heat exchanger, and stored at a constant temperature of 1°C.

Embodiment 3

[0021] It is basically the same as Example 1, except that the raw milk just extruded from the pasture at about 37°C is rapidly cooled to 2°C within 1-2 minutes through a high-efficiency plate heat exchanger, and stored at a constant temperature of 2°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com