Antifreeze essence for beverage and preparation method thereof

A technology for beverages and flavors, which is applied in the field of antifreeze flavors for beverages and its preparation, which can solve the problems of easy demulsification of flavors, achieve good stability, improve dispersibility, and maintain the effect of taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

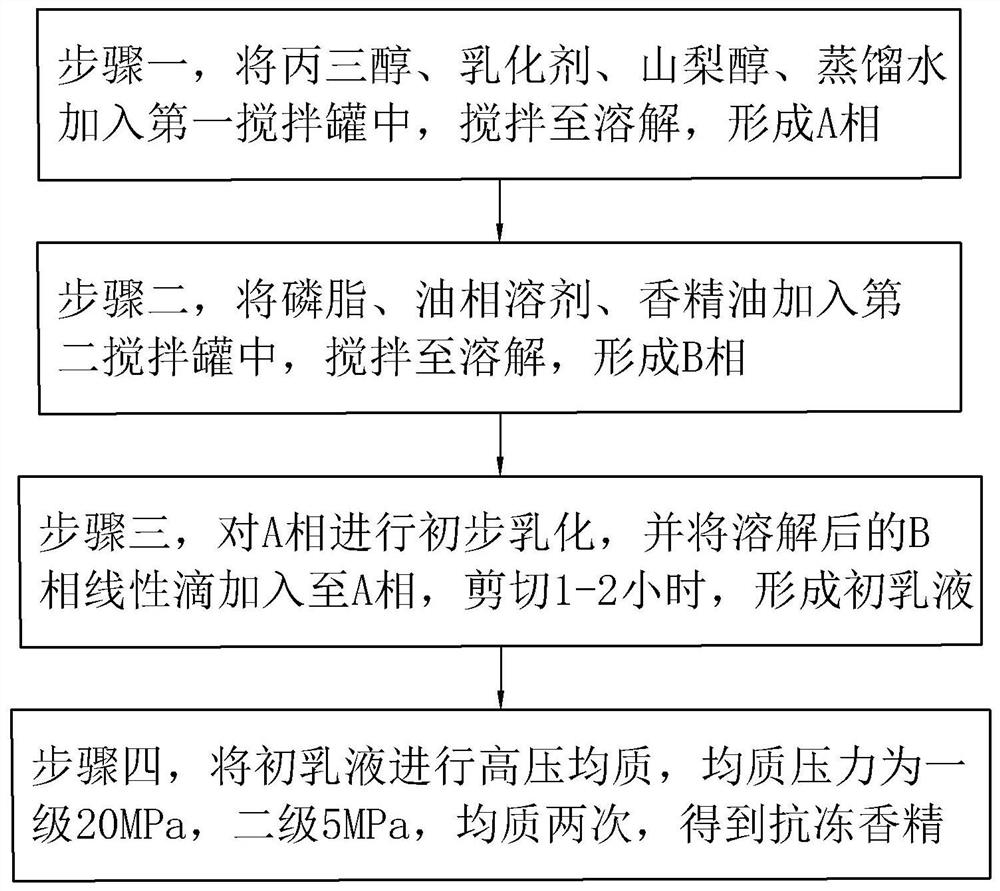

[0036] Embodiment 1: as figure 1 As shown, a kind of antifreeze essence for beverages, each component and corresponding parts by weight thereof are as shown in Table 1, and are prepared through the following steps:

[0037] Step 1, add glycerol, emulsifier, sorbitol, and distilled water into the first stirring tank, stir until dissolved, and form A phase;

[0038] Step 2, adding phospholipids, oil phase solvent, and essential oil into the second stirring tank, stirring until dissolved to form phase B;

[0039] Step 3, open the homogenizing head of the first stirring tank, carry out preliminary emulsification on phase A, and linearly drop the dissolved phase B into phase A, cut for 1-2 hours, and form a primary emulsion;

[0040] Step 4: Homogenize the primary emulsion under high pressure. The homogenization pressure is 20 MPa for the first stage and 5 MPa for the second stage. Homogenize twice to obtain the antifreeze essence.

[0041] Wherein the emulsifier is soap bark ext...

Embodiment 2-5

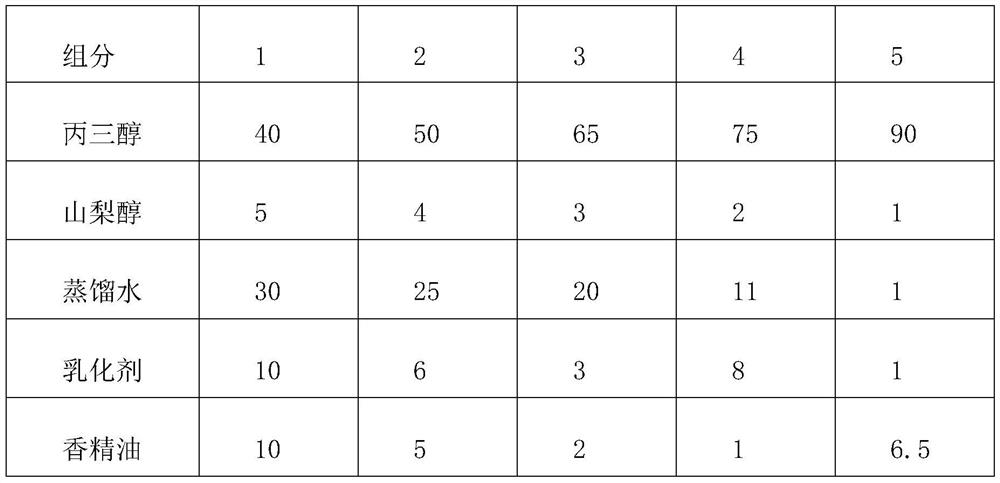

[0042] Embodiment 2-5: An antifreeze essence for beverages. The difference from Embodiment 1 is that each component and its corresponding weight percentage are shown in Table 1.

[0043] Each component and weight percent thereof in table 1 embodiment 1-5

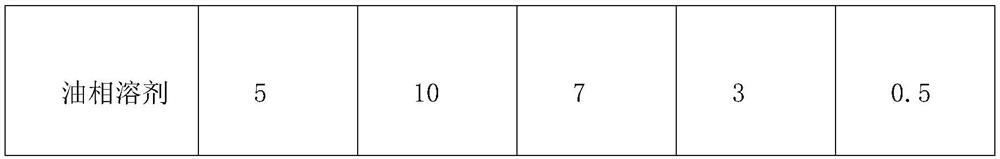

[0044]

[0045]

Embodiment 6

[0046] Embodiment 6: An antifreeze essence for beverages. The difference from Embodiment 1 is that the emulsifier is citric acid fatty acid glyceride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com