Cavity noise reduction tire and manufacturing method thereof

A tire and noise reduction technology, applied in special tires, tire parts, tires, etc., can solve problems such as increased fluidity, weak bonding properties, tire balance or adverse effects on uniformity, and achieve the effect of maintaining life.

Active Publication Date: 2019-10-01

HANKOOK TIRE WORLDWIDE

View PDF14 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the characteristics of hot-melt adhesives determine that the higher the temperature is, the lower the viscosity will be, and the fluidity will increase. Therefore, the position of the sound-absorbing material adhered to the tire will change during driving, which will affect the balance or uniformity of the tire. produce adverse effects

Although there are patents for the use of silicone series or silane-modified polyester adhesives, the pollution source on the surface of the inner liner inside the tire or the transfer of the bladder (Bladder) release agent will reduce the surface adhesion, which is affected by the tire during driving. The high temperature and large deformation effect will cause the adhesive properties to become weak

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

manufacture example 1

manufacture example 2

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Login to View More

Abstract

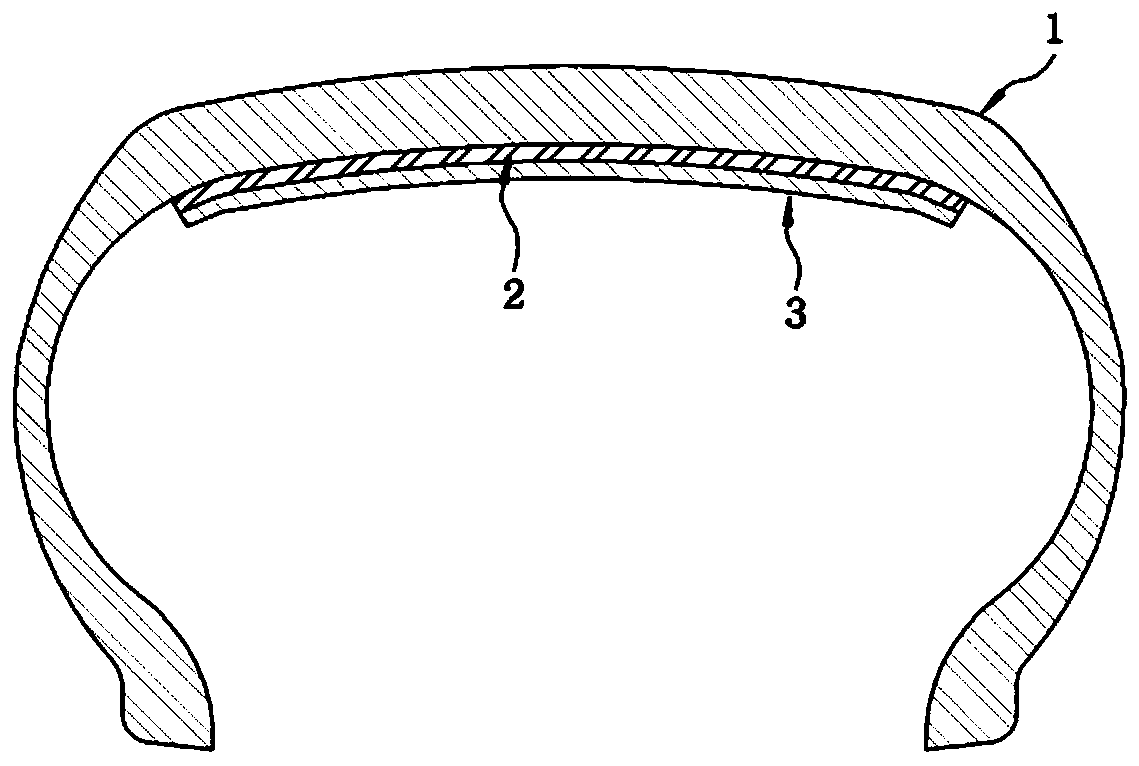

The invention relates to a cavity noise-reducing tire, comprising: an airtight layer; an adhesive layer coated on the inner side of the airtight layer; and a sound-absorbing material layer adhered to the adhesive layer. That is, the present invention provides a stable cavity noise reduction tire in which the sound absorbing material does not come off even if it generates heat and deforms during running.

Description

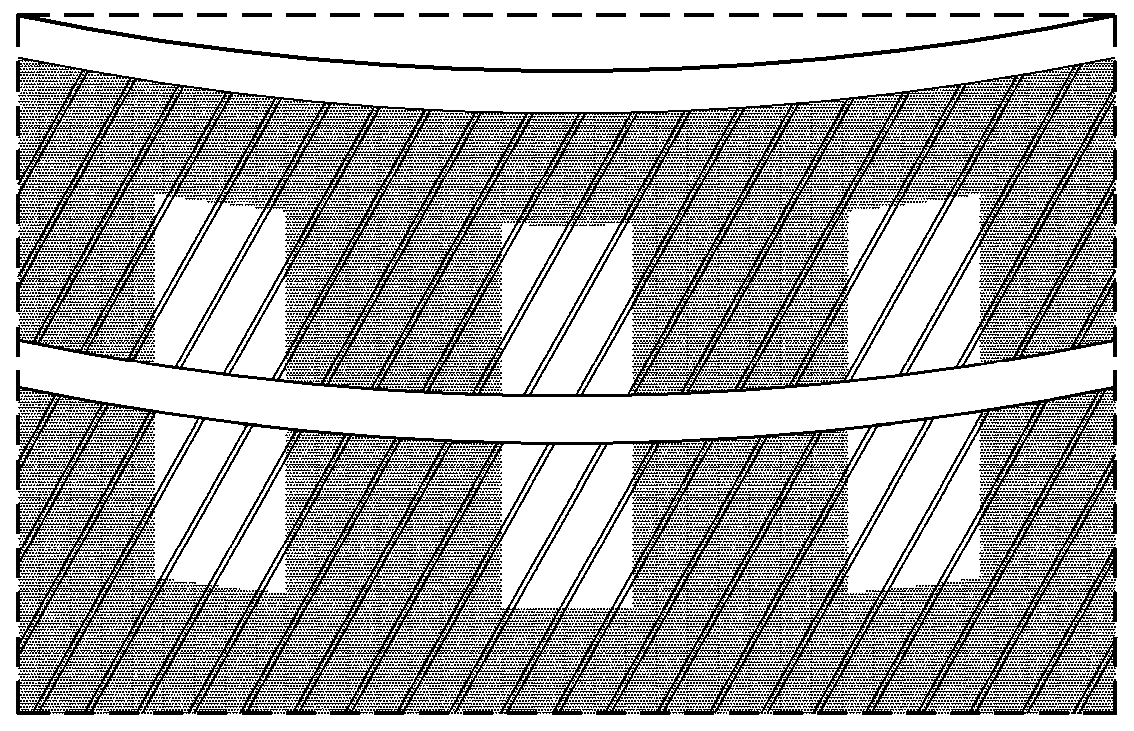

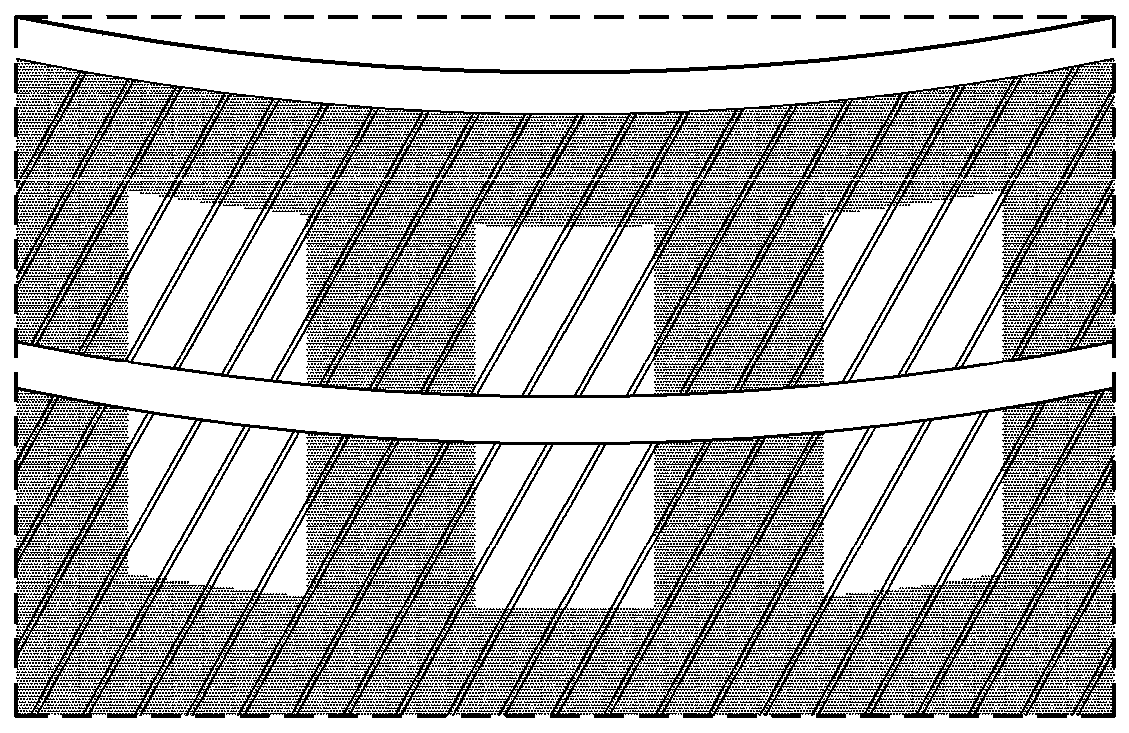

technical field The present invention relates to a method of enhancing the adhesion of tire adhesives for cavity noise reduction, and in particular to a method of using a method that does not contaminate the interior of the tire, or using an airtight Cavity noise-reducing tire with layer to enhance adhesive adhesion and method for manufacturing the same. Background technique With regard to vehicle noise, there is a gradual increase in the need to reduce the noise generated by tires with the strengthening of government regulations and the expansion of demand for electric vehicles. However, according to recent research and development trends, UHP (Ultra High Performance) tires, which have a wide tread portion where the tire contacts the road surface and have a low sidewall aspect ratio, are attracting attention. Due to the structural characteristics of this kind of tire, the rigidity of the sidewall is increased, so the structure of the tire itself cannot exert a proper dampi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B60C19/00

CPCB60C19/002B60C1/00C08L21/00B29D30/0005C08J9/00C08L75/04C09J183/04B60C1/0008C08G2350/00

Inventor 徐炳镐

Owner HANKOOK TIRE WORLDWIDE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com