Automatic conveying trolley

A technology of automatic transportation and trolley, which is applied to non-electric variable control, vehicle position/route/height control, instruments, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained in detail below in conjunction with the accompanying drawings and specific embodiments, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

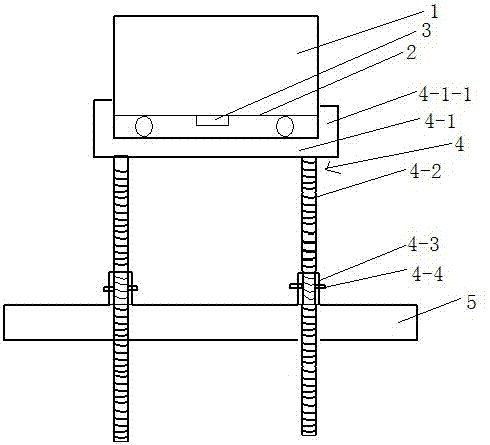

[0015] Such as figure 1 As shown, the present invention relates to an automatic transport trolley, comprising a car body 1, a chassis 2 placed at the bottom of the car body 1, a magnetic navigation sensor 3 installed on the chassis 2, a driving device for driving the trolley and connecting the chassis 2 The lifting device 4 is provided with a magnetic strip on the trolley running track 5, and the magnetic navigation sensor 3 senses the magnetic strip to make the transport trolley run along the track 5, and the lifting device 4 includes a fixed connection with the chassis 2. Connecting seat 4-1, screw rod 4-2 and motor, one end of the screw rod 4-2 is fixedly connected to the connecting seat 4-1, the motor drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com