Method for designing cross section of corrugated steel plate arch bridge based on optimal stress state

A technology of corrugated steel plate and stress state, which is applied in the direction of computer-aided design, calculation, special data processing application, etc., can solve the problems of increasing section bending moment, increasing vertical settlement of arch bridge, prone to deformation, etc., and achieves reduction Effects of horizontal thrust, reduced steel consumption, and reduced bending moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

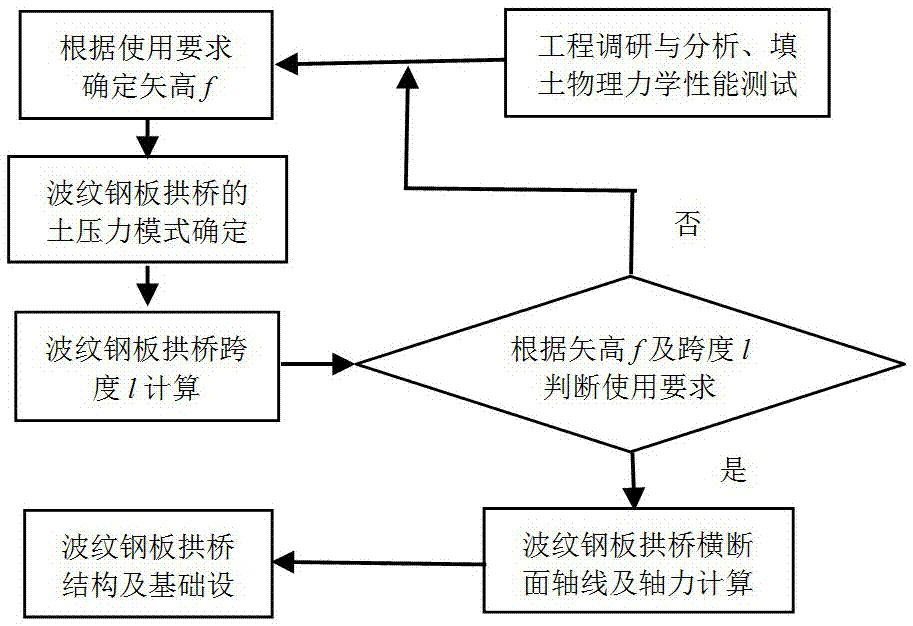

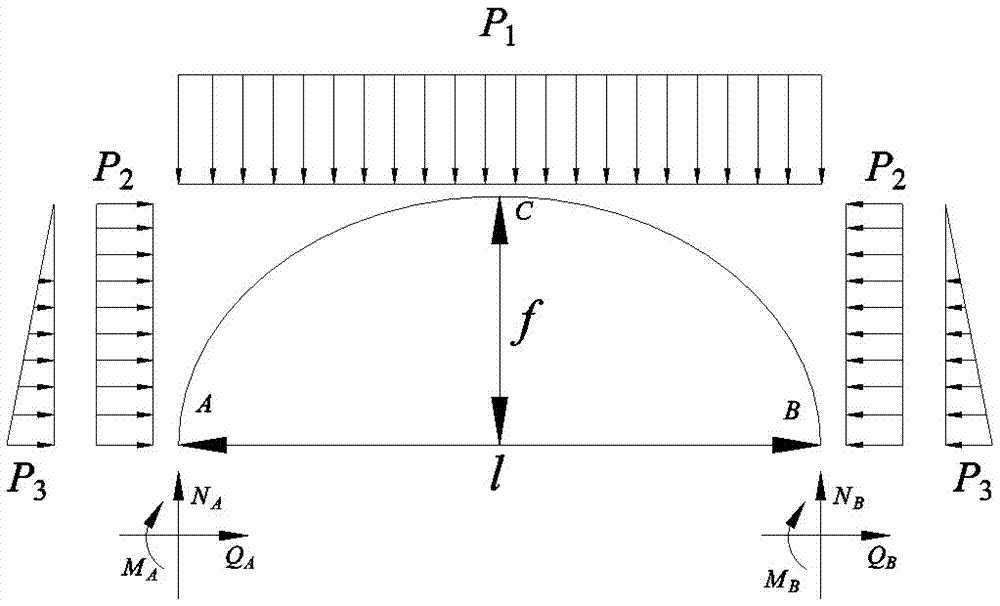

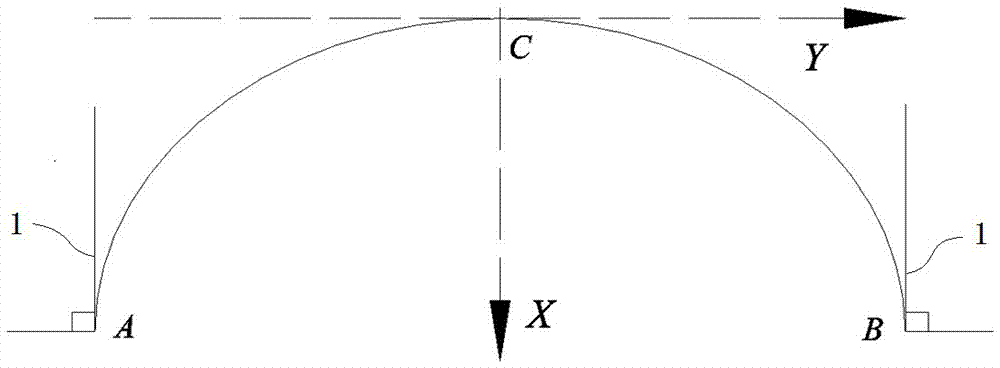

[0064] Example: such as Figure 1-6 As shown, this embodiment specifically relates to a method for designing the cross section of a corrugated steel plate arch bridge based on the optimal stress state. The thickness of the overlying soil and the mechanical properties of the overlying soil, the cross-section axis of the corrugated steel plate arch bridge is vertical at the tangent line 1 at the arch foot position, and the arch foot structure 2 is hinged; the optimal stress state referred to here It means that the theoretical bending moment of the cross section of the corrugated steel plate arch bridge is zero, and the horizontal thrust of the corrugated steel plate arch bridge at the arch foot is also zero; therefore, figure 2 Medium M A =0; M B =0;Q A =0;Q B =0; the cross-section design method of the corrugated steel plate arch bridge specifically includes the following steps:

[0065] (1) Preliminarily determine the sagittal height of the corrugated steel plate arch bri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com