Battery module cell mounting structure

A technology for installing structures and battery modules, which is applied to battery pack parts, structural parts, circuits, etc., can solve the problems of large support frame, variability of support frame, unfavorable battery box assembly, etc., and achieve the effect of fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] combine Figure 1 to Figure 7 , the present invention is further described:

[0016] The following is a detailed introduction to the cell installation structure of the battery module in combination with the entire battery module:

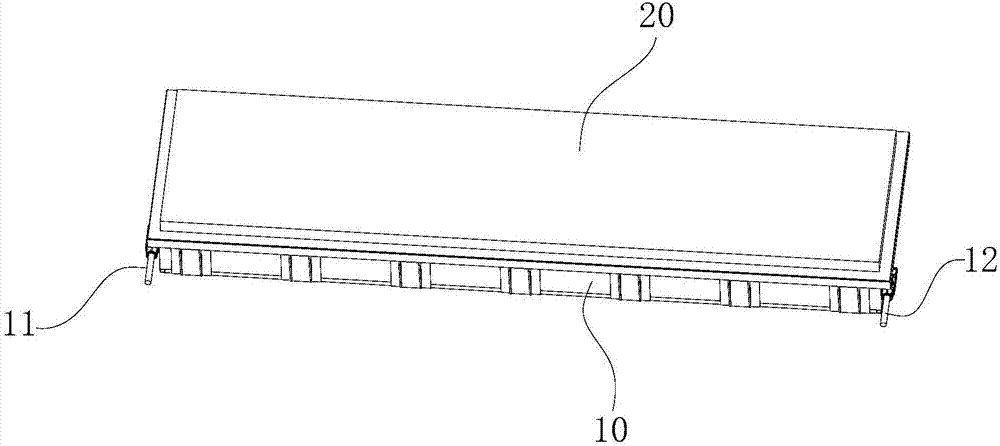

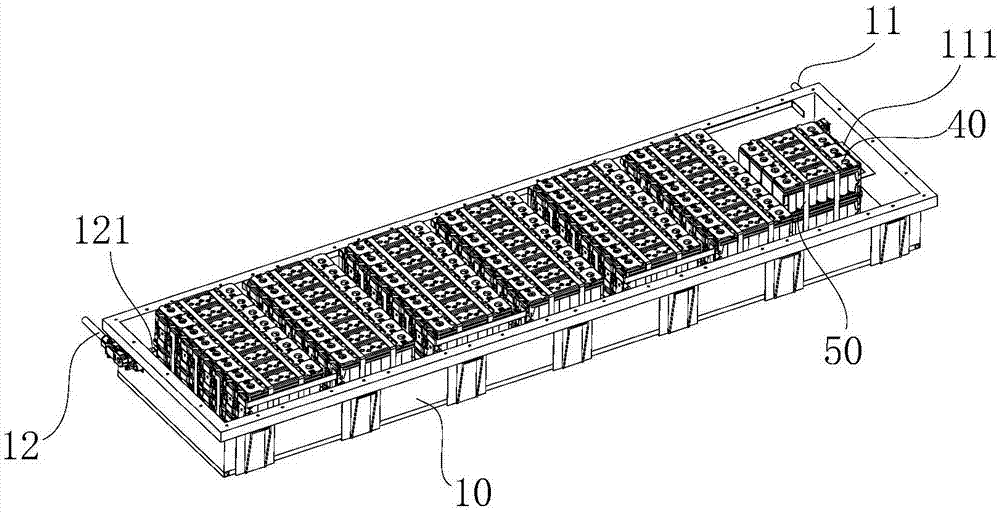

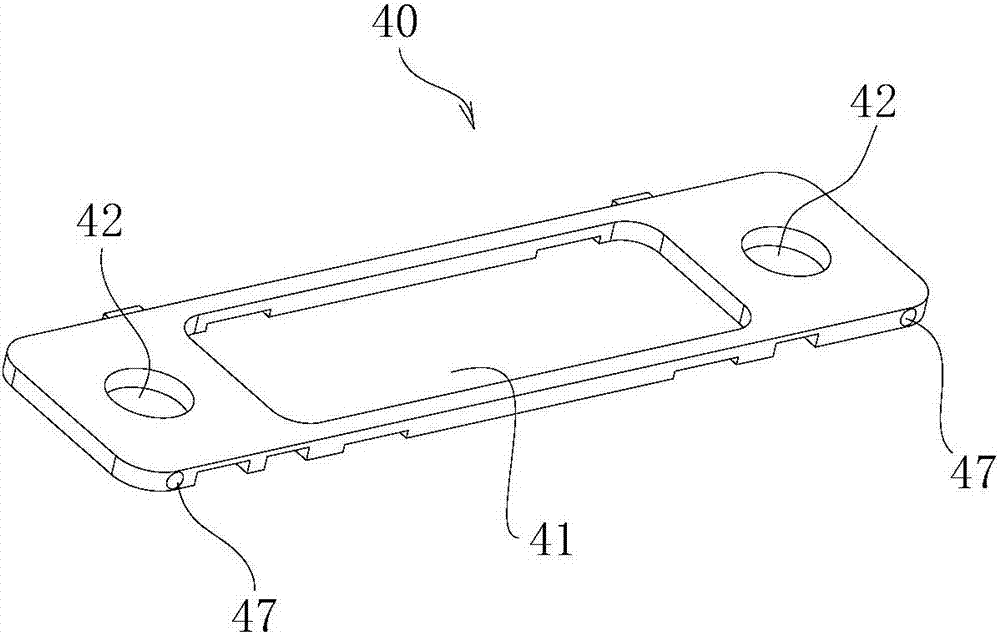

[0017] The battery module includes a bottom bracket 10 for installing the battery module, the bottom bracket 10 has an open box-like structure, the opening of the bottom bracket 10 is provided with a box cover 20, and a plurality of batteries are arranged in the bottom bracket 10 The battery pack is connected in series with each other through the electrical connecting piece 31, and the battery pack is composed of a plurality of battery cells 30, the upper end of the battery cell 30 is provided with a fixing plate 40, and the fixing plates 40 at the upper ends of the adjacent battery cells 30 are spliced together As a whole, the side walls at both ends of the bottom bracket 10 are respectively provided with a negative connection terminal 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com