Simple acid waste gas purification apparatus

A technology of acid waste gas and purification device, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, separation methods, etc. It can solve the problems of increasing contact area, harsh cleaning environment, and heavy workload, and achieves simple installation, low investment, Configure flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

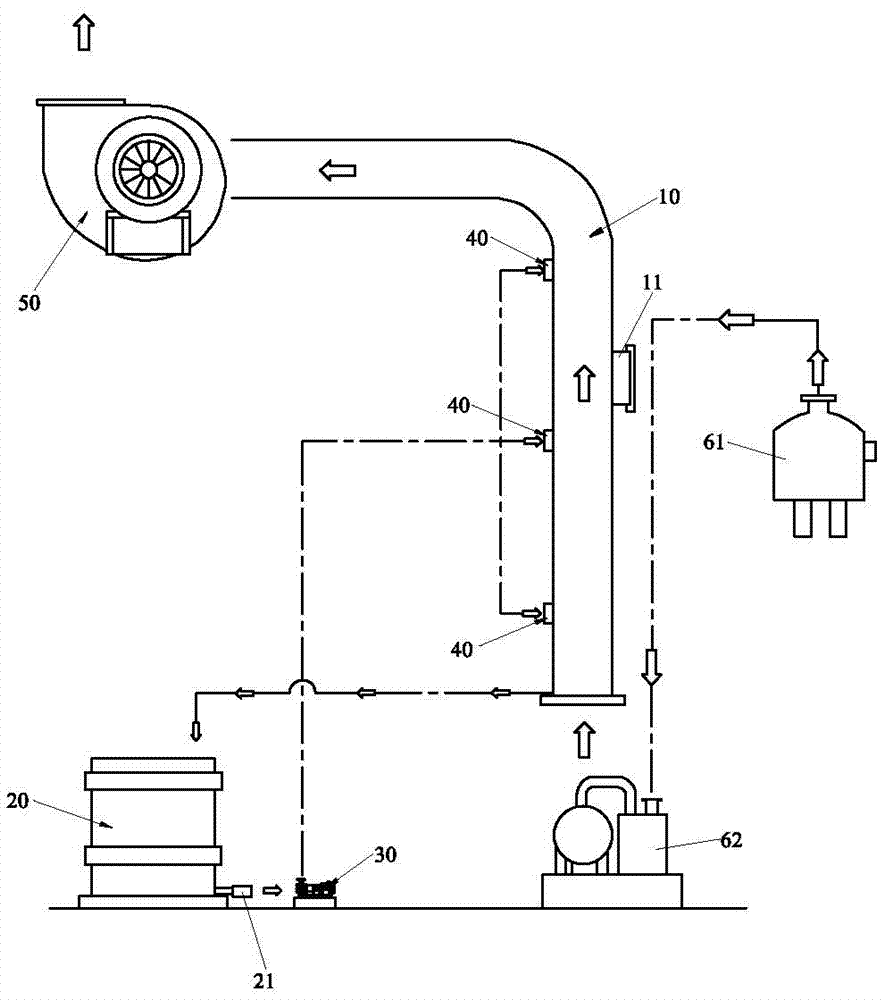

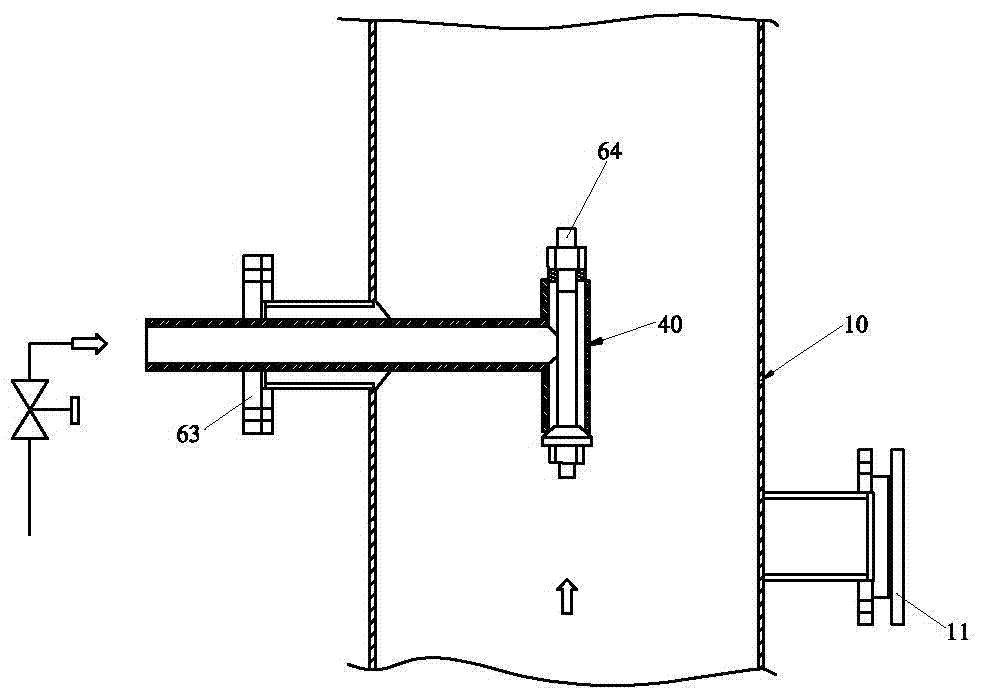

[0024] Please refer to Figure 1 to Figure 2 As shown, it shows the specific structure of the preferred embodiment of the present invention, including the vent pipe 10, the lye storage tank 20, the lye circulation pump 30, the nozzle 40 and the exhaust fan 50.

[0025] The ventilation pipe 10 accepts the waste gas discharged from the system. Specifically, a steam-water separation tank 61 is arranged on the side of the ventilation pipe 10, and the acid waste gas is stored in the steam-water separation tank 61. The acid waste gas in the steam-water separation tank 61 passes through a vacuum pump. 62 is pressed into the ventilation pipe 10;

[0026] The lye storage tank 20 communicates with the lye return port at the lower end of the ventilation pipe 10, and the outlet of the lye storage tank 20 is provided with a valve 41 to control the output of the lye.

[0027] The liquid inlet of the lye circulation pump 30 is connected with the liquid outlet of the lye storage tank 20 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com