Double-end copper wire large drawing mill

A large drawing machine and copper wire technology, applied in wire drawing dies, metal wire drawing, manufacturing tools, etc., can solve the problems of inconvenient drawing, stuck, large investment, etc., and achieve good stability, balanced force, and small friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] For ease of understanding, the present invention will be further explained in detail below in conjunction with the accompanying drawings.

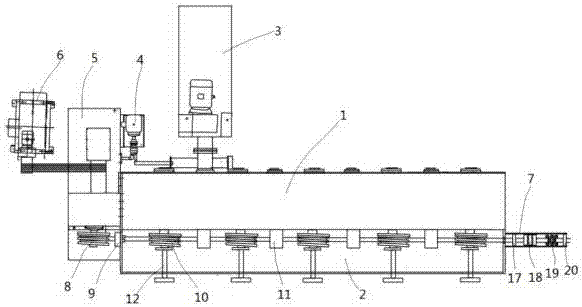

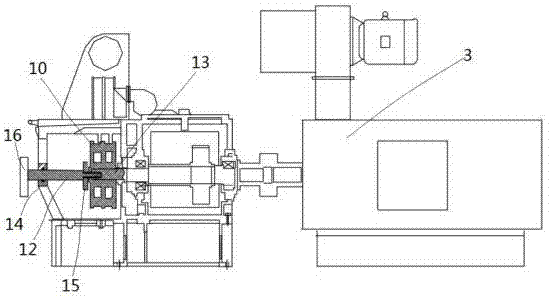

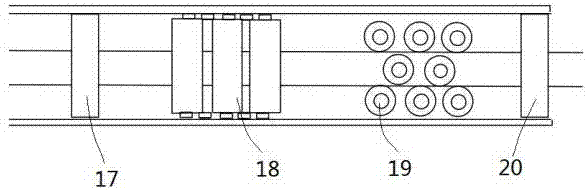

[0020] A double-ended copper wire drawing machine, such as figure 1 , 2 As shown in .3, it includes a large drawing machine body 1, the large drawing machine body 1 is provided with a drawing box 2, and a plurality of drawing wheels 10 are arranged in the drawing box 2, and the drawing wheels 10 are provided with two drawing grooves, adjacent to the drawing box A wire drawing die 11 is arranged between the wheels 10, the wire drawing die 11 is provided with two wire drawing holes, the left end of the drawing box 2 is provided with an outlet die 9, and the right end of the drawing box 2 is equipped with a wire inlet device 7, which includes The first wire entry die 20, the vertical straightening roller system 19, the horizontal straightening roller system 18, and the second wire entry die 17 are arranged in sequence in the moving di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com