Intermediate-frequency welding machine for manufacturing steel grid plate and welding method

A steel grating and welding machine technology, applied in the field of steel grating manufacturing, can solve the problems of hindering the passage of transmission lines, large current loss, low efficiency, etc., and achieve the effects of reducing processing costs, improving work efficiency, and accurately controlling the magnitude of the current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

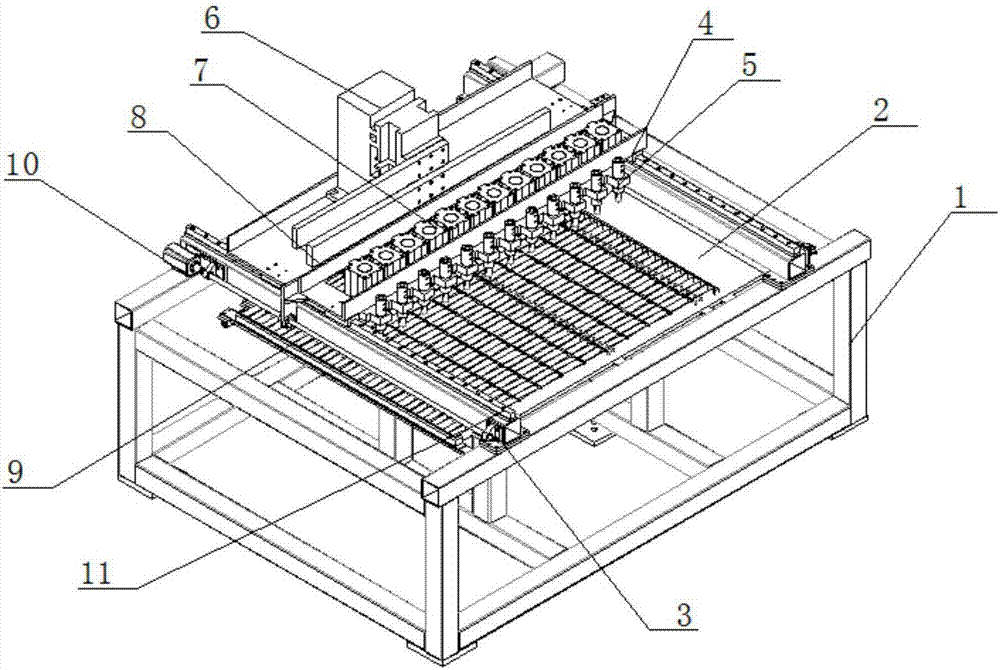

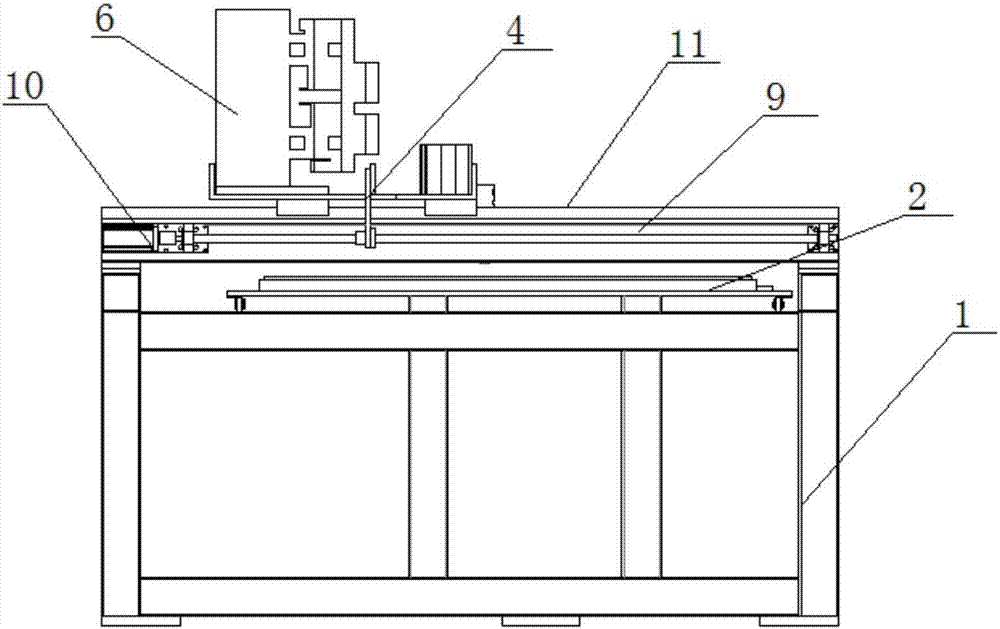

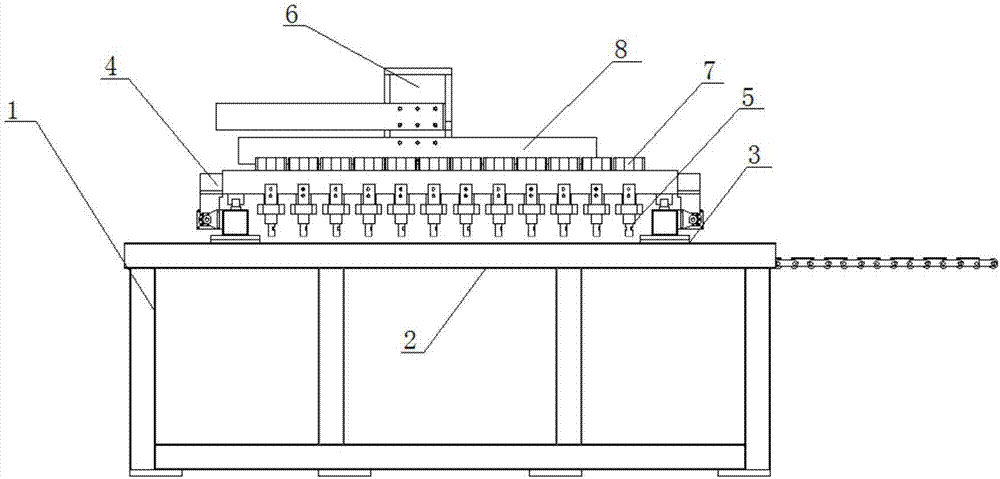

[0054] Such as figure 1 As shown, an intermediate frequency welding machine for the manufacture of steel gratings includes a frame 1, the frame 1 supports a working surface 2, the Y-axis beam 3 is installed on the frame 1, and the Z-axis beam 4 passes through the Y-axis guide rail 11 is slidably installed on the Y-axis beam 3, and a power source is fixedly installed on the Z-axis beam 4, and the power source is connected to at least one welding electrode 5.

[0055] In this embodiment, a driving method for the welding electrode to move up and down is provided. The power source includes a transformer 6 and a cylinder 7. Both the transformer 6 and the cylinder 7 are fixedly installed on the Z-axis beam, and the welding electrode 5 is connected to On the cylinder 7 , the welding electrode 5 is electrically connected to the welding frequency electrode 8 , and the welding frequency electrode 8 is connected to a power source through a transformer 6 . The transformer 6 is used to ch...

Embodiment 2

[0060] This embodiment provides an intermediate frequency welding method using an intermediate frequency welding machine for steel grating manufacturing as in Embodiment 1, including the following steps:

[0061] Step 1: Prepare raw materials: Prepare a flat steel frame which is welded together by several flat steels and several horizontal bars of equal length. The flat steels are provided with a plurality of flat steel beams parallel to each other, and each flat steel beam Support grooves of the same shape and size are provided at several identical positions on one side edge;

[0062] Step 2: Prepare the fixture: prepare the fixture, and the fixture is provided with a limit groove corresponding to the outline of the flat steel frame described in step 1;

[0063] Step 3: Pre-installation: Install the flat steel frame described in step 1 into the corresponding limit groove on the fixture described in step 2, so that the outline of the flat steel frame matches the limit groove, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com