Improved slitting device

A technology for guide rails and workbenches, which is applied to work accessories, manufacturing tools, stone processing equipment, etc., can solve the problems of low work efficiency and high labor intensity of workers, and achieve the effect of simple structure, reduced labor efficiency, and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

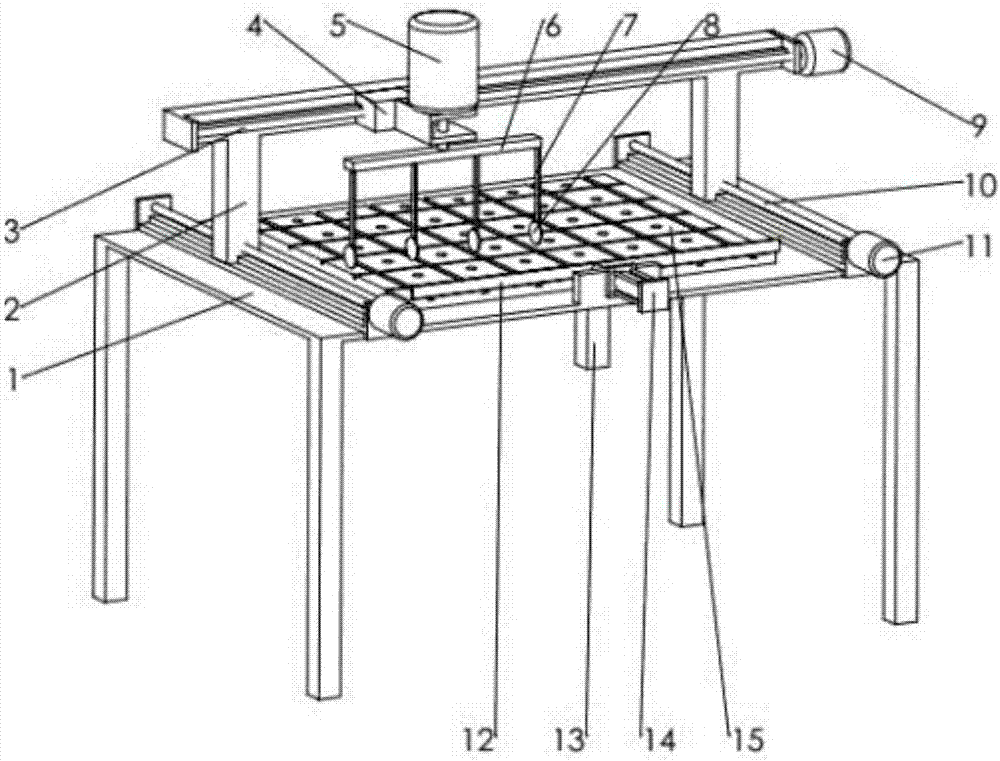

[0012] combined with figure 1 An improved cutting device of the present invention will be further described.

[0013] An improved slitting device, including a workbench 1, two mutual first guide rails are installed on the workbench 1, a vacuum suction cup 15 is installed between the two first guide rails, and a vacuum generator is also installed on the workbench 1 13. The vacuum generator 13 communicates with the vacuum suction cup 15. A support 2 is also installed on the first guide rail. The support 2 is also provided with a support drive mechanism. The support 2 is also provided with a second guide rail that is horizontally arranged and perpendicular to the first guide rail. , a slider 4 is installed on the second guide rail, a slider drive mechanism is provided on the slider 4, a support rod 6 is also horizontally and rotatably installed on the slider 4, and a plurality of vertically arranged The connecting rod 7 is equipped with a cutting wheel 8 at the lower end of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com